Coating liquid with latex particle reflection deducting capability as well as preparation method and application of coating liquid

A technology of anti-reflection and latex particles, which is applied in textiles and papermaking, fiber type, fiber treatment, etc., can solve the problems such as the appearance of additives that are not mentioned, and achieve the effect of avoiding dependence and simple and easy finishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Weigh 0.2g of sodium lauryl sulfate and add it to 74.77g of water. After mechanical stirring and mixing, add 10g of methyl methacrylate and 8g of divinylbenzene to the solution. After mechanical stirring, put Water bath in the pass N 2 After 15 minutes, after heating up to 75°C, dissolve 0.03g of potassium persulfate in 5g of water and add it to the above reaction mixture. After 2.5h of reaction, the reaction solution (i.e. latex core structure emulsion) is obtained, and slowly drip into the reaction solution Add a mixed solution of 1.5g butyl acrylate and 0.5g methacryloxypropyltrimethoxysilane, and finish adding dropwise within 0.5h. After continuing to react for 3 hours, the temperature was raised to 90° C. and kept for 30 minutes to obtain an anti-reflection coating liquid composed of latex particle solution Product 1 with a core-shell structure, with a solid content of 20%.

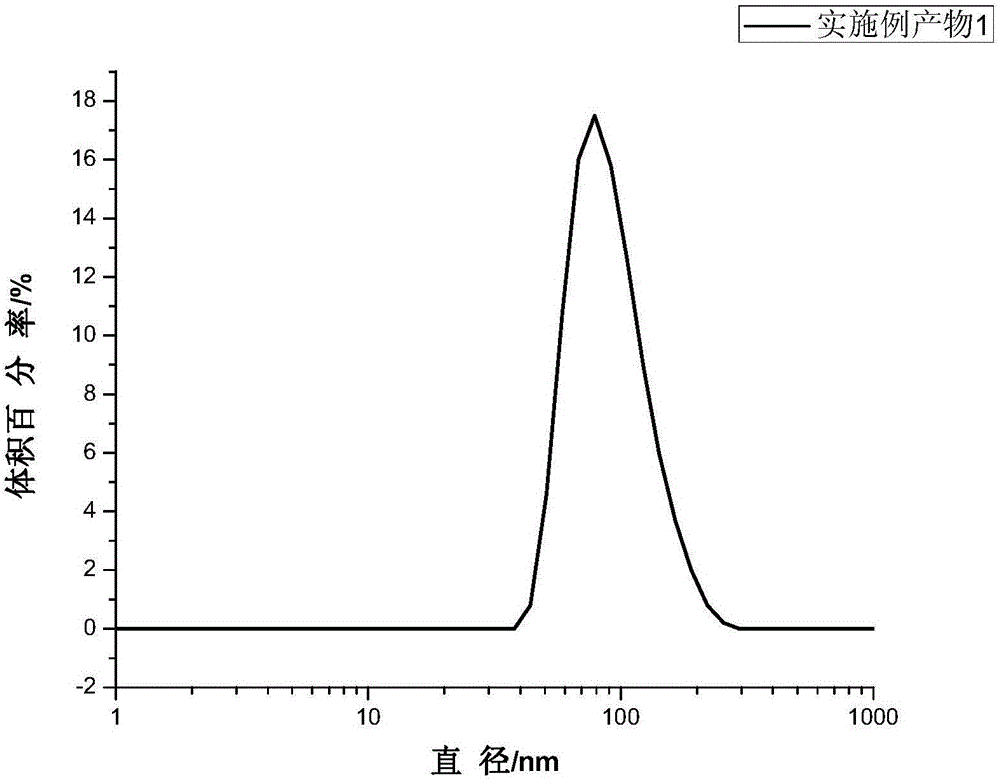

[0046] After diluting the product 1, the particle size distribution curve was measured re...

Embodiment 2

[0050] The sodium dodecylbenzene sulfonate that takes 0.5g joins in the water of 67.46g, after mechanical stirring mixes uniformly, adds the methyl methacrylate of 12g and the ethylene glycol dimethacrylate of 8g in the solution, mechanically After stirring evenly, put it in a water bath and turn on N 2 After 20 minutes, when the temperature reaches 70°C, dissolve 0.04g of potassium persulfate in 5g of water and add it to the above reaction mixture. After 2 hours of reaction, slowly add 5g of butyl acrylate and 2g of methacryloyloxy The mixed solution of propyltrimethoxysilane was added dropwise within 2 hours. After continuing the reaction for 2.5 hours, the temperature was raised to 85° C. and kept for 45 minutes to obtain an anti-reflection coating solution composed of latex particle solution Product 2 with a core-shell structure, with a solid content of 27%.

[0051] Figure 4 TEM photo of product 2. from Figure 4 It can be seen that the product 2 has formed a core-sh...

Embodiment 3

[0053] Weigh 1g of sodium alkyl sulfonate and add it to 68.95g of water, stir and mix evenly, add 10g of methyl methacrylate and 5g of divinylbenzene to the solution, stir evenly, put it into the water bath ZTO N 2 20min, after the temperature reaches 80°C, dissolve 0.05g of ammonium persulfate in 5g of water and add it to the above reaction mixture. After reacting for 3h, slowly add 8g of acrylonitrile and 2g of [4-(methacrylic Acyloxy) butyl] pentamethylsiloxane mixture, dropwise within 2h. After continuing the reaction for 3 hours, the temperature was raised to 90° C. and kept for 40 minutes to obtain an anti-reflection coating solution composed of latex particle solution product 3 with a core-shell structure, with a solid content of 25%.

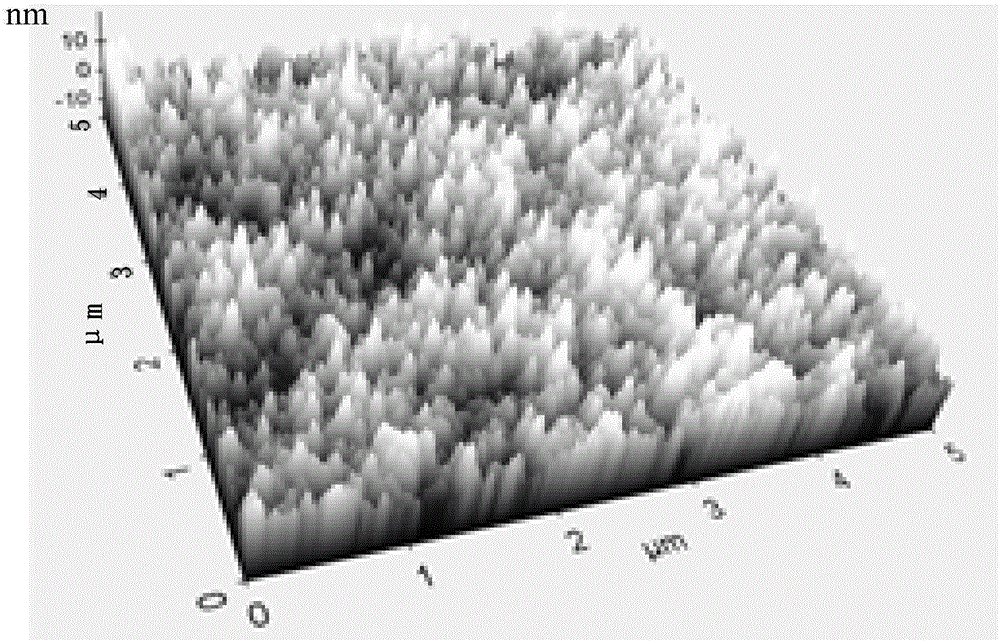

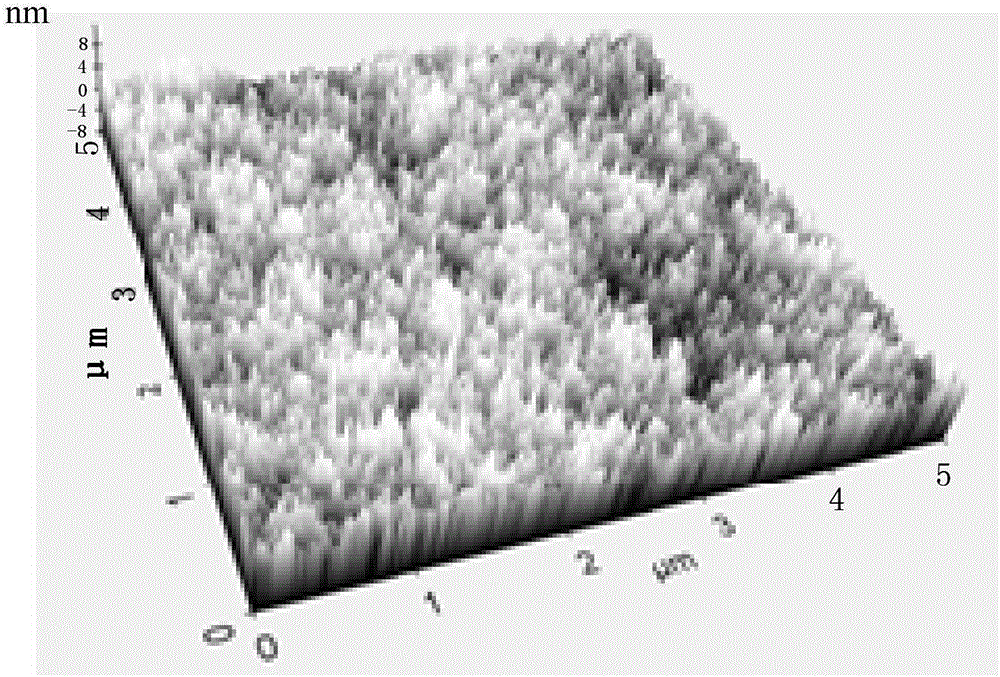

[0054] Figure 5 It is the AFM photograph of the latex film of product 3. It can be seen that the surface of the coating film has a concave-convex nano-rough structure. Depend on image 3 with Figure 5 It can be seen that compared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com