Slurry lamination automatic supply device with variable area range and control method

An automatic supply and paste technology, applied in the field of additive manufacturing, can solve the problems that the uniformity of the paste coating and printing quality cannot be guaranteed, the feeding method is single and fixed, and the paste is unevenly covered, so as to save the paste , the auxiliary material area can be changed, and the effect of improving the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

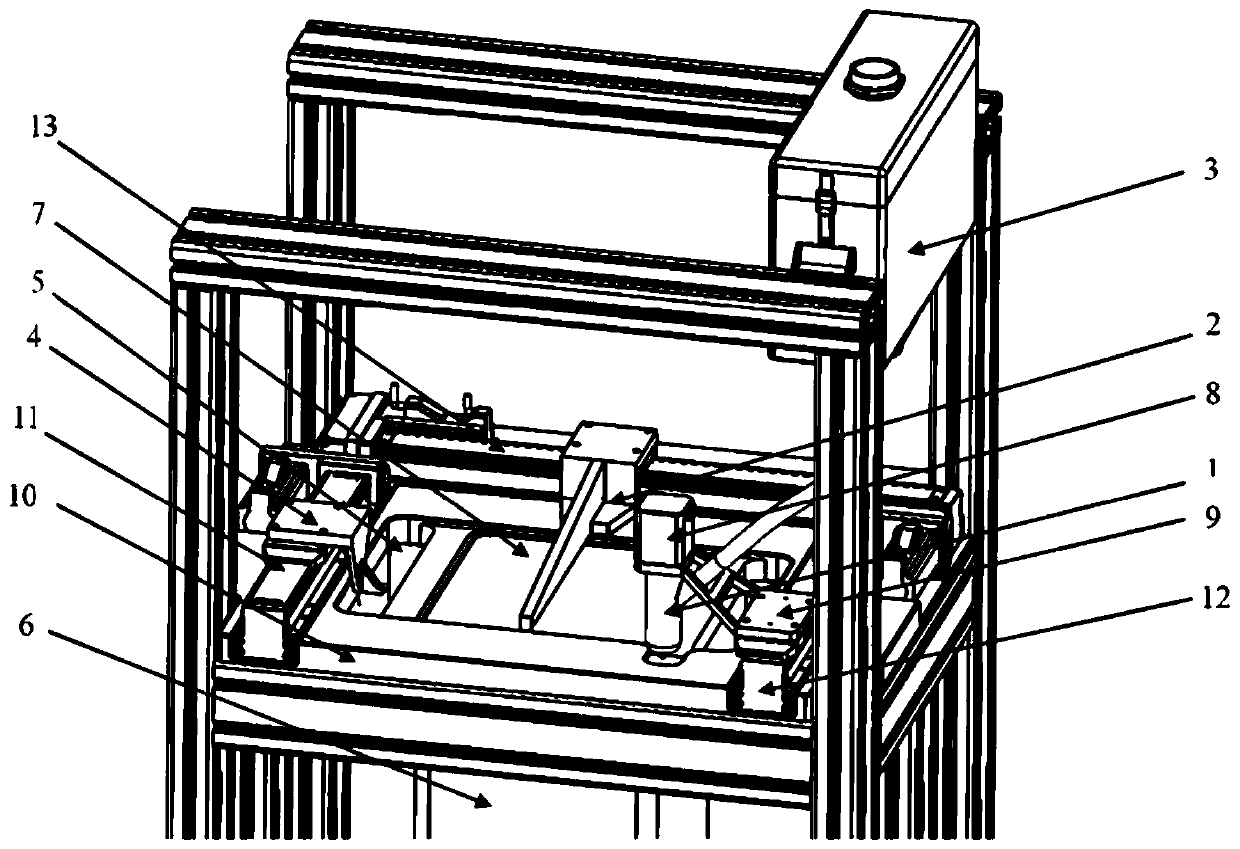

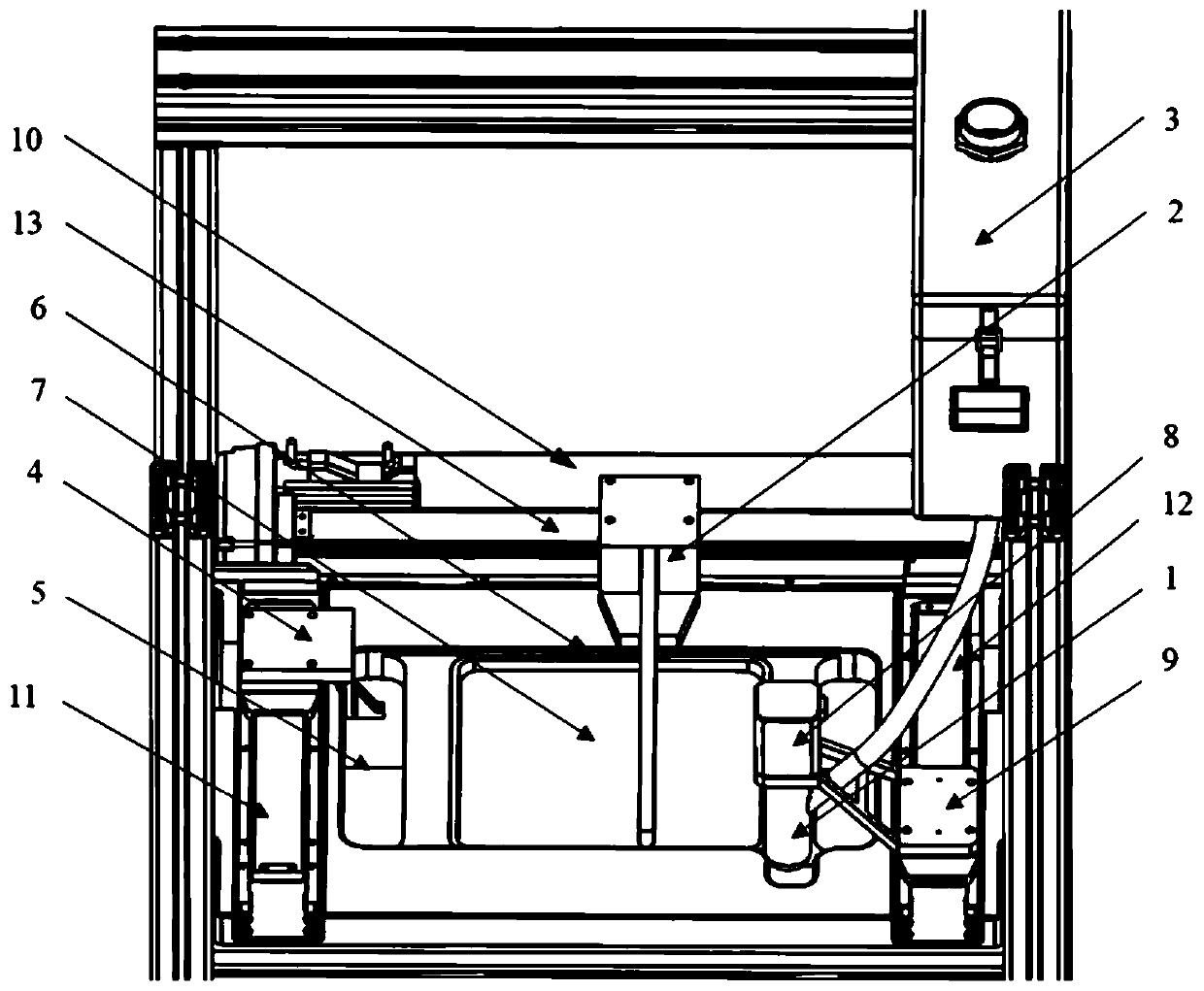

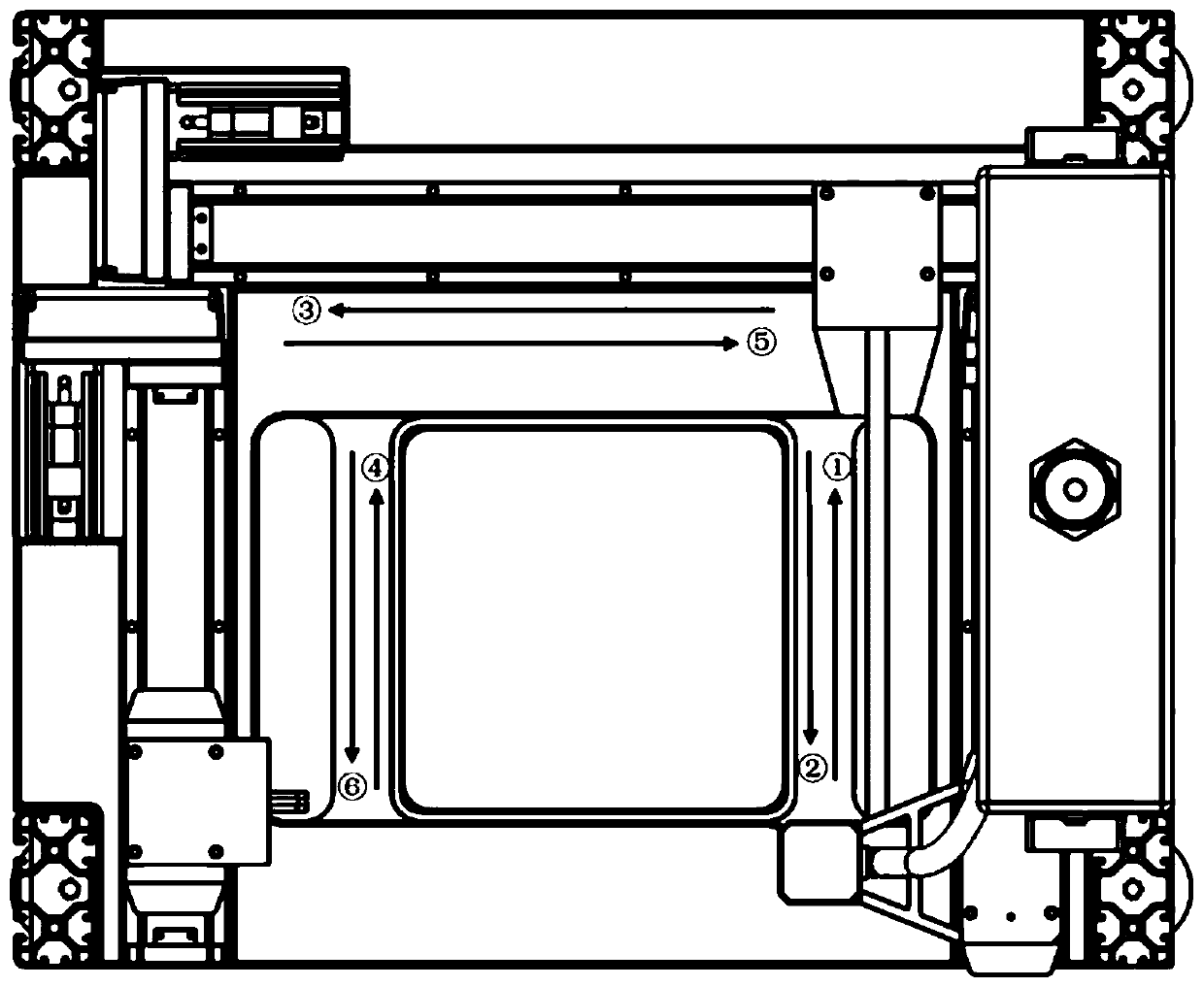

[0043] like figure 1 , figure 2 As shown, the present invention relates to a slurry lamination automatic supply device with a variable range, including a feeding nozzle 1, a scraper 2, a material storage cylinder 3, a pressurized air pump, a scraper cleaning device 4, a waste collection cylinder 5, a forming Cylinder 6, printing platform 7, feeding nozzle drive motor 8, feeding nozzle support frame 9, installation backplane 10, No. 1 X-axis moving platform 11, No. 2 X-axis moving platform 12, Y-axis moving platform 13 and screw propulsion Device 14; the scraper 2 is fixed on the Y-axis mobile platform through a combination of bolts and jackscrews, and its relative position with the Y-axis mobile platform can be adjusted by bolts and jackscrews so as to have a leveling function; the scraper cleaning device 4 It is mechanically connected with the No. 1 X-axis mobile platform 11 through the combination of bolts and jackscrews; the feeding nozzle 1 is connected with the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com