Large-scale concrete element mold and use method thereof

A technology of moulds and components, applied in building types, mould shells/templates/work frames, on-site preparation of building components, etc., can solve the problems of poor surface quality of concrete segments, low production efficiency and loose structure, etc. To achieve the effect of easy transportation, small footprint and saving slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment the present invention is described in further detail:

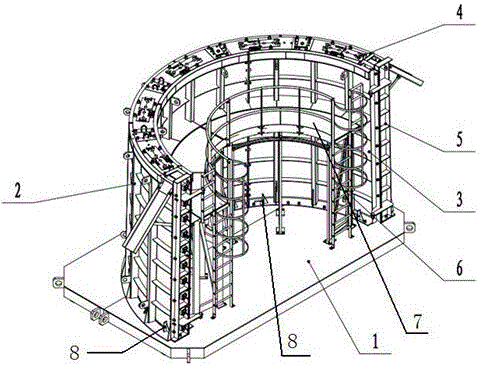

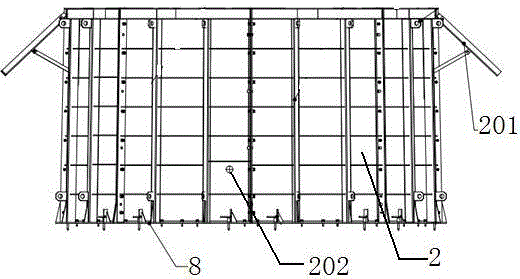

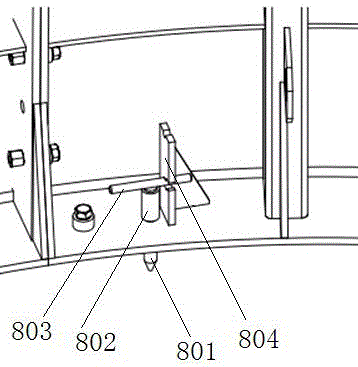

[0031] Such as figure 1 As shown, the present invention is a large-scale concrete element mold, which is used for pouring a semicircular concrete construction element. The present invention is mainly made up of several components such as seat plate 1, arc-shaped top cover 4, strip-shaped end cap 5, arc-shaped outer mold 2 and arc-shaped inner mold 3, seat plate 1 is flat plate, end cap 5 is elongated, and top cover 4 is C font. The inner mold 3 and the outer mold 2 are both semicircular, the radius of the inner mold 3 is smaller than that of the outer mold 2, and the difference between the radii of the inner mold 3 and the outer mold 2 is the thickness of the concrete construction element.

[0032] The inner mold 3 and the outer mold 2 are vertically installed above the seat plate 1 parallel to each other, the top cover 4 is installed above the inner mold 3 and the outer mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com