Method for sizing fiber filament by coating through hanging drop and used device thereof

A fiber filament and drip coating technology is applied in the field of fiber filament sizing, which can solve the problems of complex sizing device, large amount of slurry and high cost, and achieve the effects of reducing the input of human resources, less slurry, and long adding cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

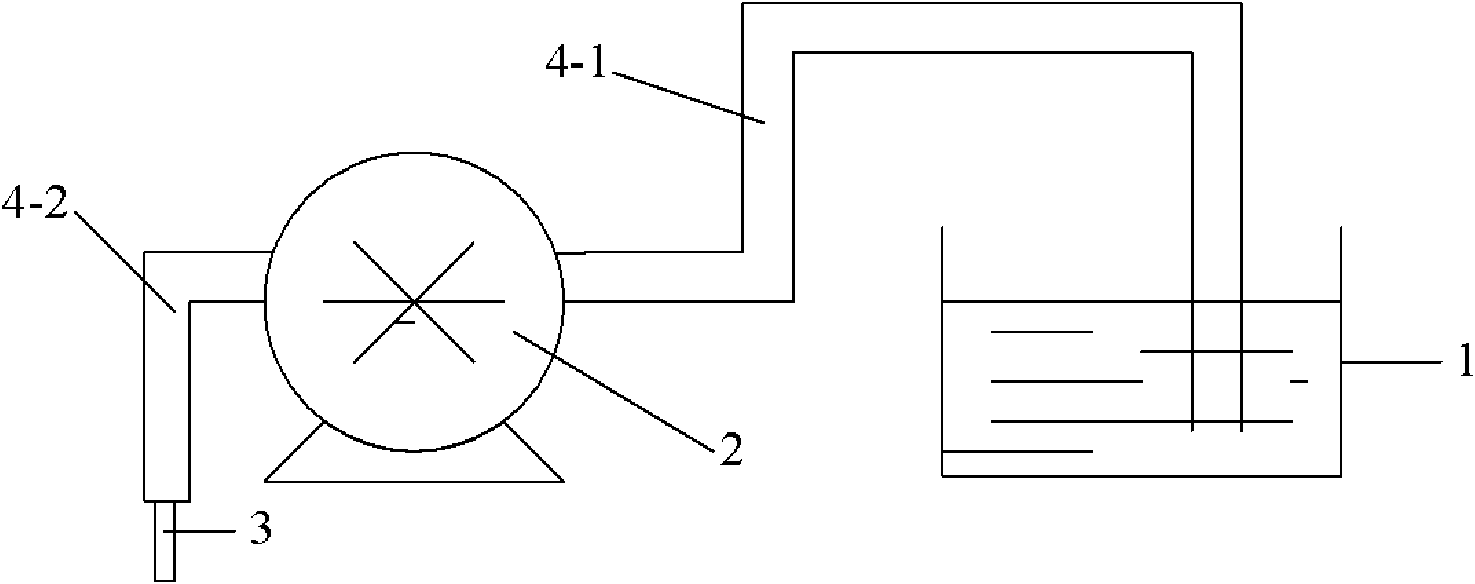

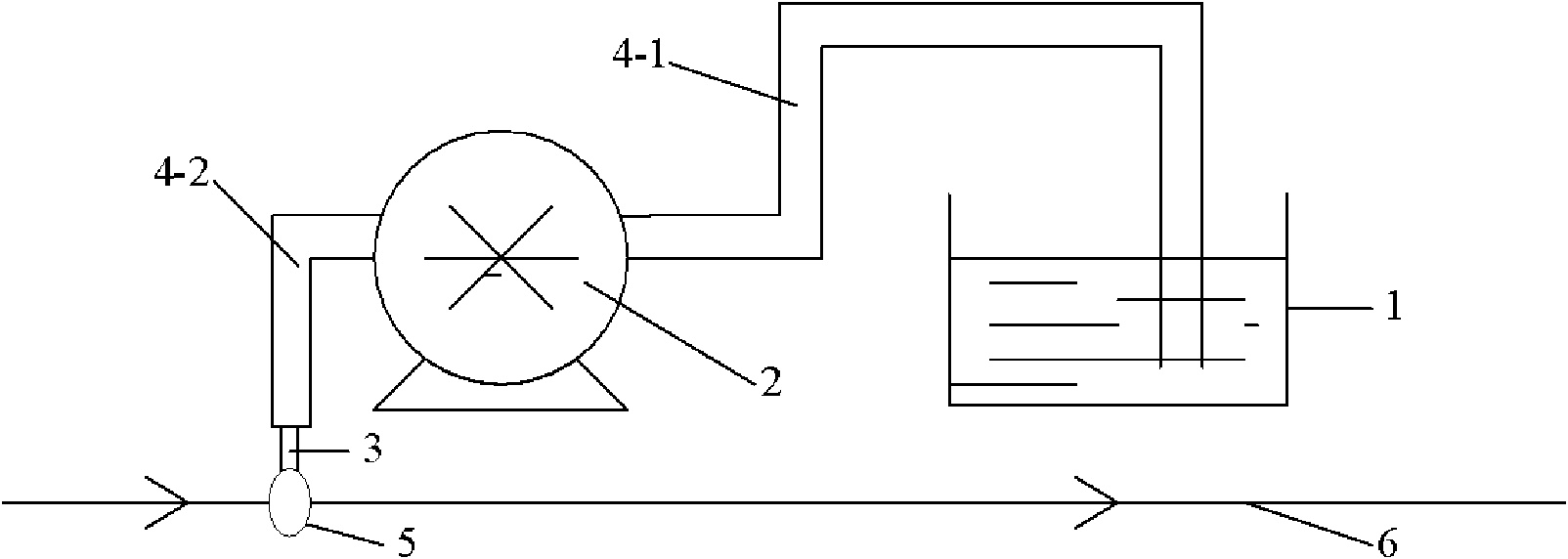

[0010] Specific Embodiment 1: In this embodiment, a hanging drop coating and sizing method for fiber filaments is to pass the fiber filaments through the inside of the hanging drops of the slurry, wherein the fiber collection speed is 0.6-1 m / min.

[0011] In this embodiment, the slurry exists in the form of hanging drops under the interaction of its own surface tension and gravity, and then the fiber filaments are driven by the take-up roller to continuously pass through the interior of the slurry hanging drops, thereby realizing the sizing of the fiber filaments. The amount of slurry required by this embodiment is small, which saves the slurry and reduces the cost, which is 1 / 5 of the amount of slurry required by the existing dipping method.

[0012] In this embodiment, the speed of fiber collection is determined by the properties of the slurry. The fluidity of the slurry is high, and the fiber collection speed is fast. When the fluidity of the slurry is poor, the fiber colle...

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment differs from Embodiment 1 in that the fiber collection speed is 0.7-0.9 m / min. Other parameters are the same as in the first embodiment.

[0014] This embodiment can be used to process slurries in ethanol containing 10% by weight epoxy resin.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiment 1 in that the fiber collection speed is 0.8 m / min. Other parameters are the same as in the first embodiment.

[0016] This embodiment can be used to process slurries in ethanol containing 2% by weight or 5% by weight epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com