Carbon fiber grooved roller sizing device

A carbon fiber and grooved roll technology, which is applied in the field of carbon fiber manufacturing, can solve the problems of high pulp consumption, decreased carbon fiber quality, sticking of the squeezing roll, etc., to reduce costs and labor intensity, increase fiber bundles, and reduce the amount of pulp. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The purpose of the present invention will be further described in detail through specific examples below, and the examples cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following examples.

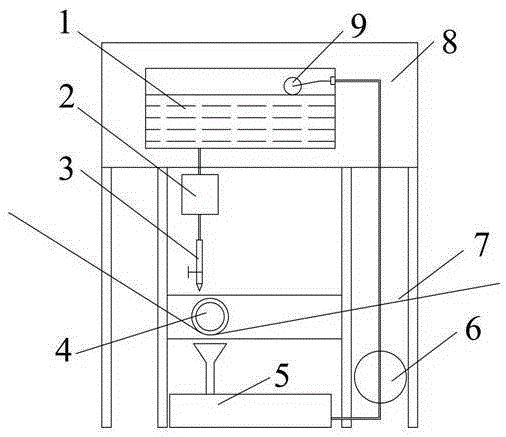

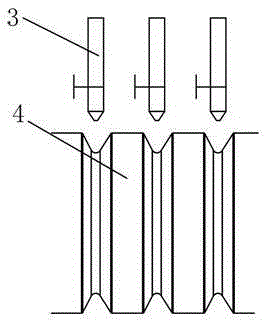

[0024] Such as figure 1 As shown, a carbon fiber groove roller sizing device includes: a slurry tank 1 fixed on a slurry tank fixing plate 8, a flow controller 2 connected to the bottom of the slurry tank 1 through pipelines in sequence, and an outlet valve with a gate valve. The slurry nozzle 3, the flow rate of the slurry is regulated by the flow controller above the slurry nozzle, which plays the purpose of controlling the amount of sizing. The bottom of the slurry outlet 3 is provided with a sizing groove roller 4 with grooves on the surface. The outlet nozzle 3 is arranged opposite to the groove of the sizing groove roller 4, and a backflow groove 5 is arranged below the sizing groove roller 4, and a carbon f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com