Glass fiber soakage agent for reinforcing ABS plastic and AS plastic and preparation method and application of glass fiber soakage agent

A technology of ABS plastic and glass fiber, applied in the field of glass fiber sizing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

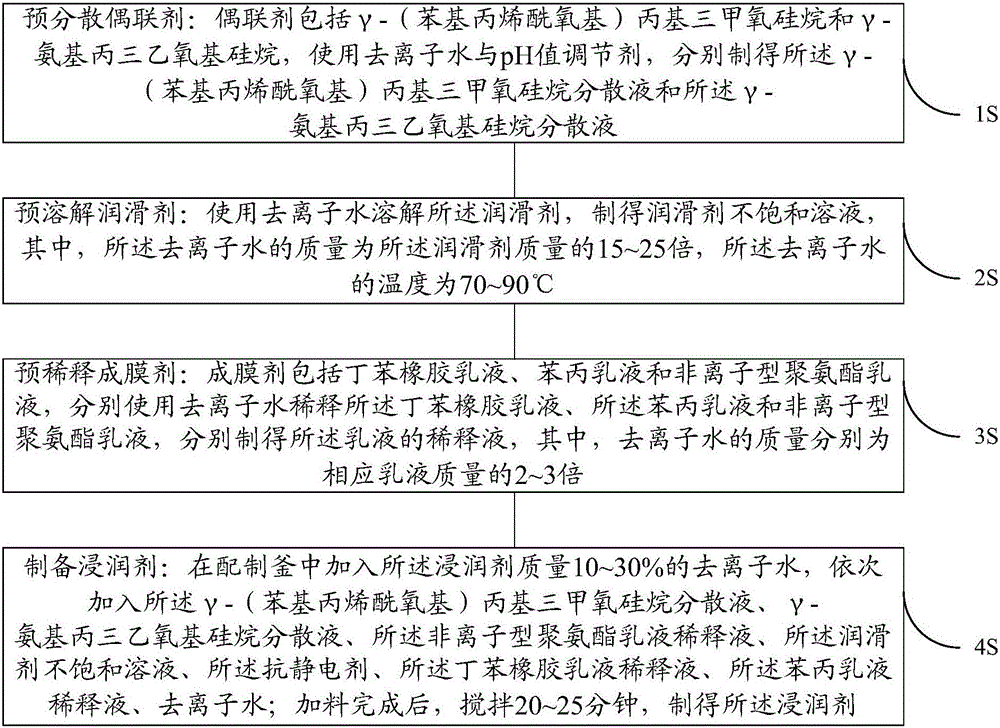

Method used

Image

Examples

Embodiment 1

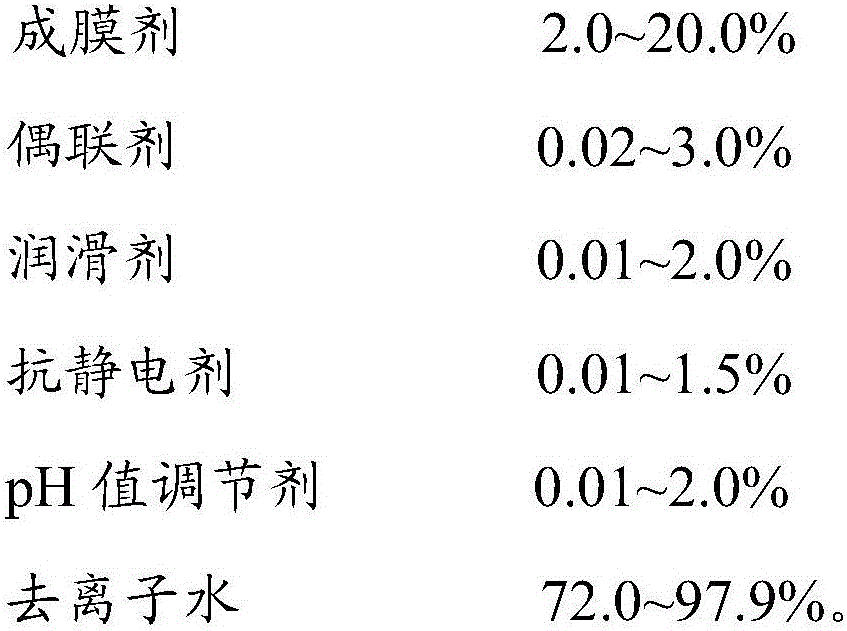

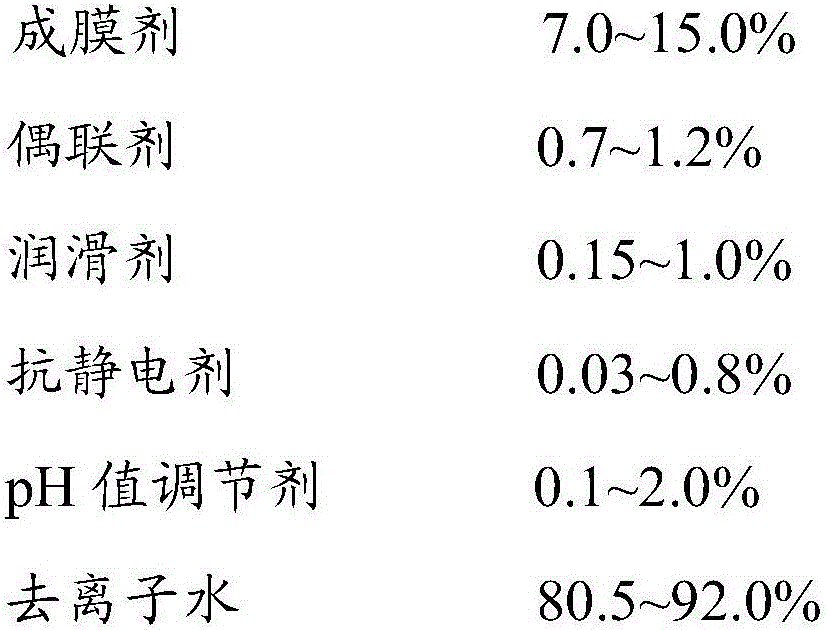

[0057] Weigh each component by mass percentage, respectively weigh 0.55% of coupling agent 1, 0.10% of coupling agent 2, 0.08% of lubricant, 0.03% of antistatic agent, 4.0% of film-forming agent 2, 4.0% % film former 3, 1.0% pH adjuster and 90.24% deionized water.

[0058] Among them, the coupling agent 1 is γ-(phenylacryloyloxy)propyltrimethoxysilane, the coupling agent 2 is γ-aminopropyltriethoxysilane, the lubricant is microcrystalline wax emulsion, and the antistatic agent is Polyoxyethylene fatty quaternary ammonium salt, film-forming agent 2 is medium and low molecular weight styrene-acrylic emulsion produced by Jushi Chemical Branch Factory, wherein the particle size of the emulsion is between 0.08-0.20 microns, the pH value is 5.5-6.5, and the Tg is between 18-25 Between ℃, the solid content is 40%, and the film-forming agent 3 is the Neoxil JS-108 raw material produced by Italian DSM company. This raw material is a kind of nonionic aliphatic polyurethane emulsion, and...

Embodiment 2

[0066] Weigh each component by mass percentage, respectively weigh 0.80% of coupling agent 1, 0.30% of coupling agent 2, 0.08% of lubricant, 0.03% of antistatic agent, 1.0% of film-forming agent 1, 6.6 % film former 2, 4.6% film former 3, 1.0% pH adjuster and 85.59% deionized water.

[0067] Wherein, the coupling agent 1 is γ-(phenylacryloyloxy)propyltrimethoxysilane, the coupling agent 2 is γ-aminopropyltriethoxysilane, and the lubricant is nonionic sorbitol fatty acid ester emulsion and Microcrystalline wax emulsion, antistatic agent is methyl sulfate salt, film-forming agent 1 is styrene-butadiene rubber emulsion TX-104 produced by Jushi Chemical Branch Factory, wherein the particle size is between 0.09 and 0.30 microns, and the solid content is 40 %, Tg is between -10 and -5°C, pH is controlled at 4.0-6.0, and viscosity is at 150mpa.s. Film-forming agent 2 is medium and low molecular weight styrene-acrylic emulsion produced by Jushi Chemical Branch Factory, wherein the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com