High-wettability glass fiber impregnating compound and preparation method thereof

A glass fiber and wettability technology, applied in the field of high wettability glass fiber sizing agent and its preparation, can solve problems such as gaps in infiltration requirements, and achieve the effects of easy operation, good uniformity and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

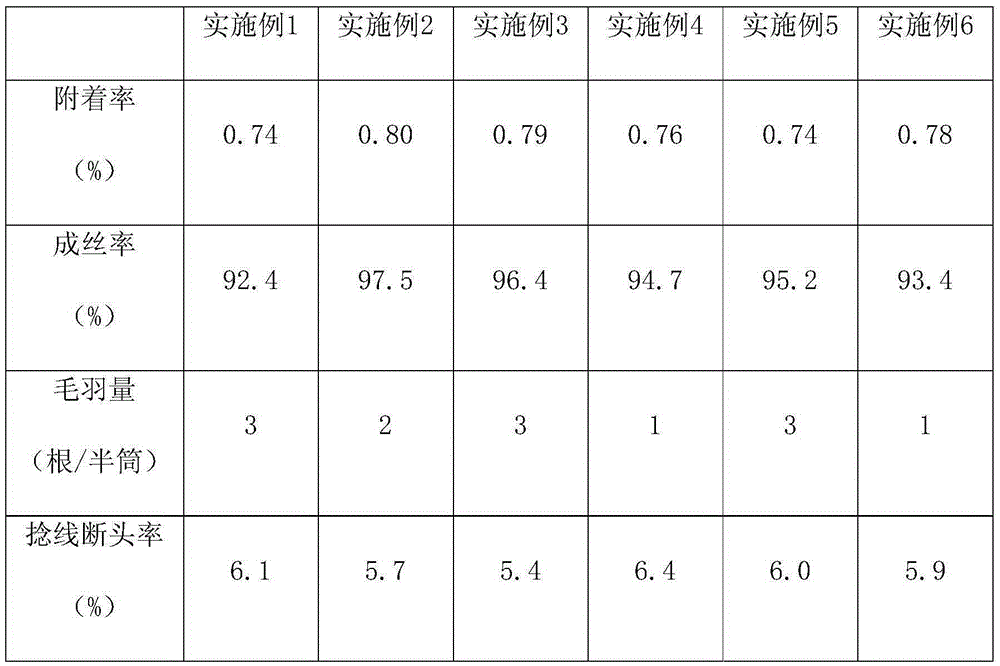

Examples

Embodiment 1

[0033] A component of a glass fiber sizing agent with high wettability, in parts by weight, comprising:

[0034] 5 parts of polyoxyethylene polyoxypropylene block copolymer and quaternary ammonium salt type cationic surfactant,

[0035] Epoxy equivalent is 45 parts of water-based epoxy resin emulsion and water-based polyurethane emulsion sizing agent of 415-437,

[0036] Grain Extract Rice Bran 10 parts,

[0037] 3 parts of polyoxyethylene type surfactant and fatty acid ester sulfate,

[0038] 1 part of citric acid and oxalic acid,

[0039] 2 parts of hydrolyzed chitosan,

[0040] 10 parts of dicumyl peroxide and vinyltriethoxysilane,

[0041] Softened deionized water 60 parts.

[0042] Concrete preparation method comprises the following steps:

[0043] (1) Add citric acid and oxalic acid with a volume ratio of 1:1 to softened deionized water, adjust the pH value of the solution to 3.2, stir for 30-50 minutes, until the mixture is complete, slowly add polyoxyethylene wit...

Embodiment 2

[0048] A component of a glass fiber sizing agent with high wettability, in parts by weight, comprising:

[0049]15 parts of polyoxyethylene polyoxypropylene block copolymer and quaternary ammonium salt type cationic surfactant,

[0050] Epoxy equivalent is 50 parts of water-based epoxy resin emulsion and water-based polyurethane emulsion sizing agent of 415-437,

[0051] Grain Extract Rice Bran 20 parts,

[0052] 8 parts of polyoxyethylene surfactant and fatty acid ester sulfate,

[0053] 5 parts of citric acid and oxalic acid,

[0054] 6 parts of hydrolyzed chitosan,

[0055] 15 parts of dicumyl peroxide and vinyltriethoxysilane,

[0056] Softened deionized water 80 parts.

[0057] Concrete preparation method comprises the following steps:

[0058] (1) Add citric acid and oxalic acid with a volume ratio of 1:1 to the softened deionized water, adjust the pH value of the solution to 4.3, stir for 50 minutes, until the mixture is complete, slowly add polyoxyethylene polyox...

Embodiment 3

[0063] A component of a glass fiber sizing agent with high wettability, in parts by weight, comprising:

[0064] 10 parts of polyoxyethylene polyoxypropylene block copolymer and quaternary ammonium salt type cationic surfactant,

[0065] Epoxy equivalent is 47 parts of water-based epoxy resin emulsion and water-based polyurethane emulsion sizing agent of 415-437,

[0066] Grain Extract Rice Bran 15 parts,

[0067] 5 parts of polyoxyethylene surfactant and fatty acid ester sulfate,

[0068] 3 parts of citric acid and oxalic acid,

[0069] 4 parts of hydrolyzed chitosan,

[0070] 12 parts of dicumyl peroxide and vinyltriethoxysilane,

[0071] Softened deionized water 70 parts.

[0072] Concrete preparation method comprises the following steps:

[0073] (1) Add citric acid and oxalic acid with a volume ratio of 1:1 to the softened deionized water, adjust the pH value of the solution to 3.7, stir for 40 minutes, until the mixture is complete, slowly add polyoxyethylene polyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com