Method for rapidly evaluating soft water erosion resistance capability of hydraulic inorganic cementing material

An inorganic gelling material, hydraulic technology, applied in the analysis of materials, material analysis by electromagnetic means, instruments, etc., can solve the problem of not being able to quickly evaluate the ability of materials to resist soft water erosion, representativeness, accuracy and repeatability of results Poor performance, insufficient objectivity of test results, etc., achieve the effect of reducing the requirements of test site and maintenance conditions, saving test time, and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

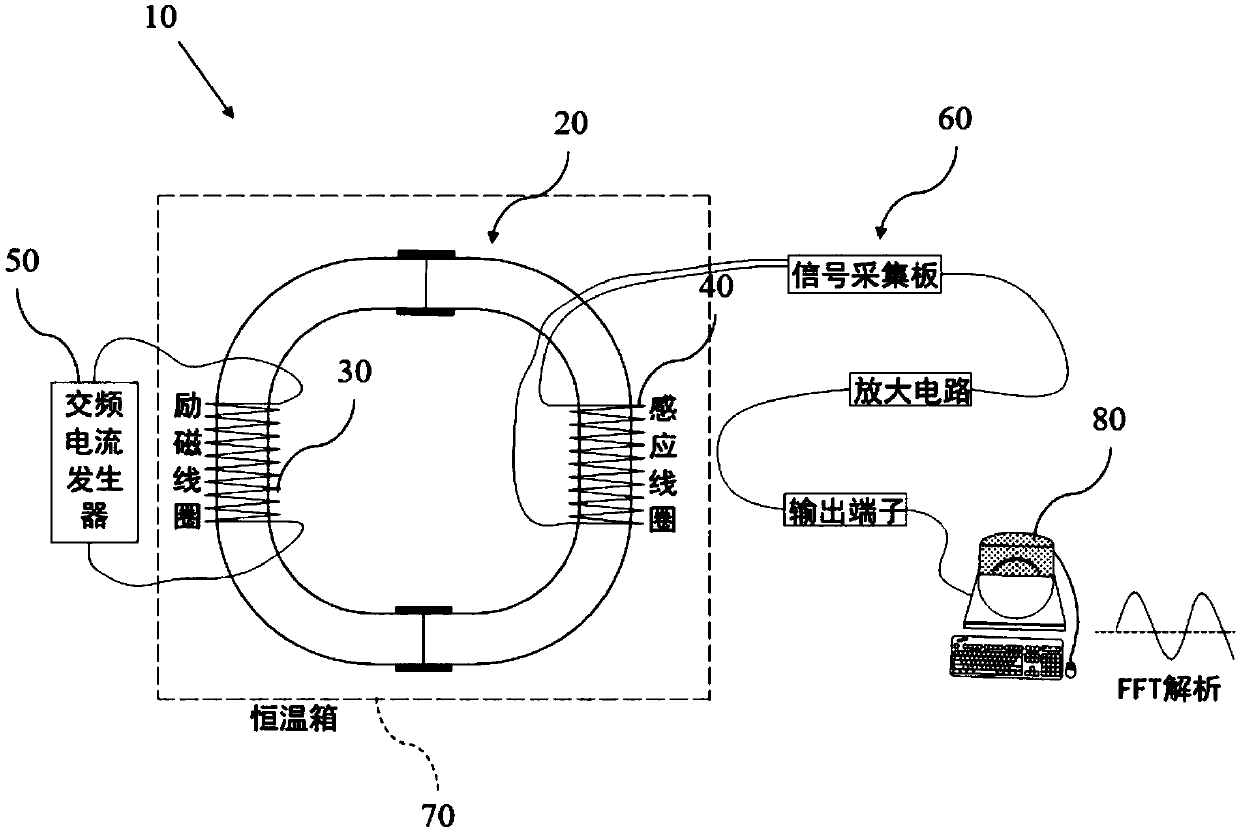

Method used

Image

Examples

Embodiment 1

[0072] The actual test results based on this method show that the judgment result of the water resistance coefficient I on the soft water erosion resistance of hydraulic inorganic gelling materials is consistent with the judgment result of the softening coefficient K. According to the interpretation of the material softening coefficient K in "Civil Engineering Materials" edited by Zhao Fangran (Zhao Fangran. Civil Engineering Materials. Shanghai: Tongji University Press, first edition, 2011:20-21), "the softening coefficient K of the material > 0.85 It shows that it has good resistance to soft water erosion and can be used for important structures in water or humid environments; while the softening coefficient K<0.75 of the material indicates that its ability to resist soft water erosion is poor and can only be used for light damp or secondary structures. To structure."

[0073] We use magnesium oxychloride cement (MC), Portland cement (PII), ordinary Portland cement (PO), rap...

Embodiment 2

[0079] In embodiment two, adopt the method of the present invention to evaluate the anti-soft water erosion ability of certain phosphate slag cement (PSA) in 24.6 ℃ environment:

[0080] Step 1. Slurry preparation and loading:

[0081] Take about 3000g of phosphate rock slag cement and pour it on a metal tray, spread it gently with a scraper, then place it in an electric blast drying oven, and dry it at 150°C for 24 hours until it is finally weighed repeatedly. The fluctuation of slag cement quality is about 0.8%.

[0082] Then accurately weigh 800g from the fully dried phosphate slag cement as a sample for testing. Accurately weigh 300g of distilled water according to 0.38 times the mass of the sample, and then make a slurry according to the method specified in "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Methods" (GB / T 1346-2011).

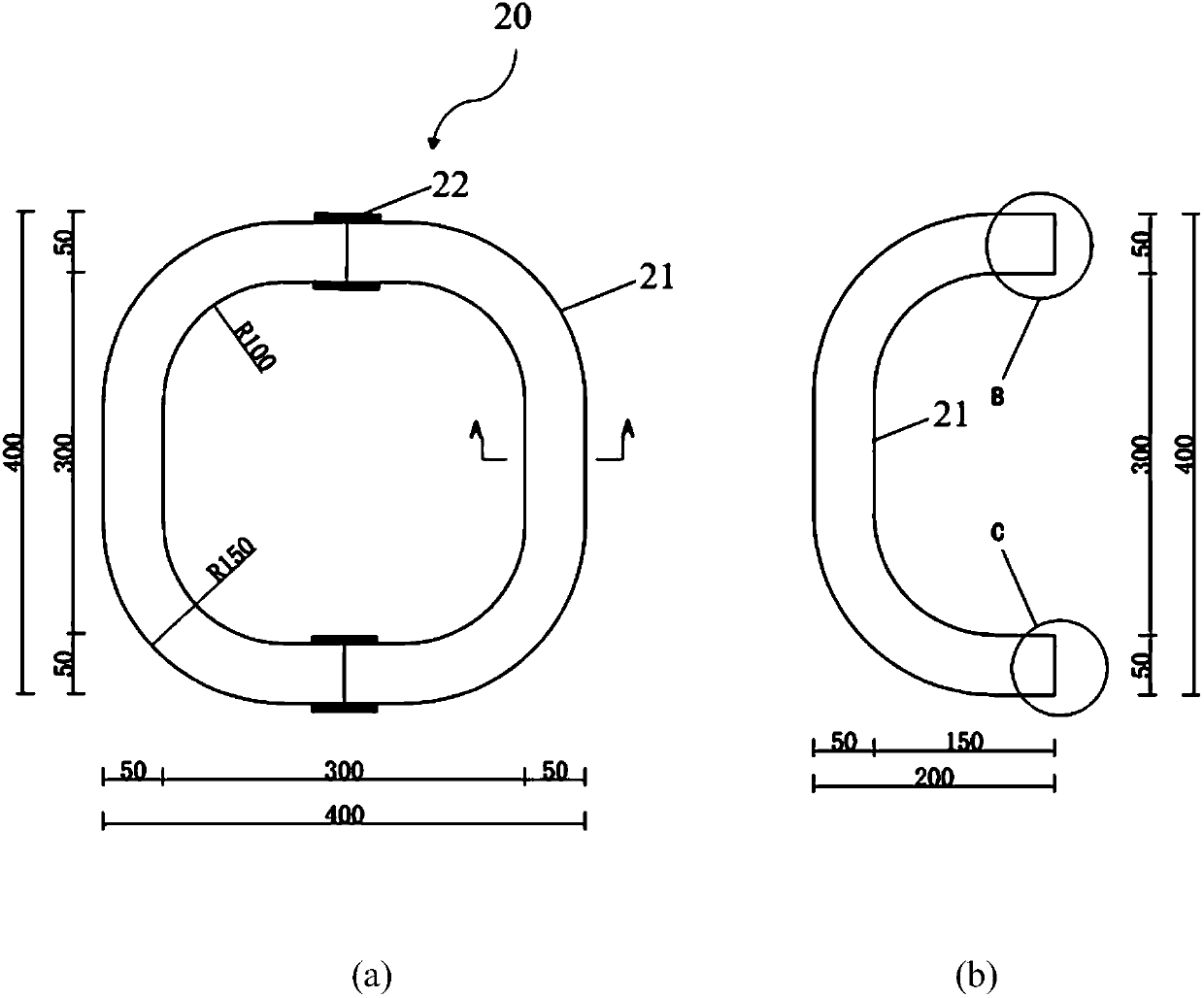

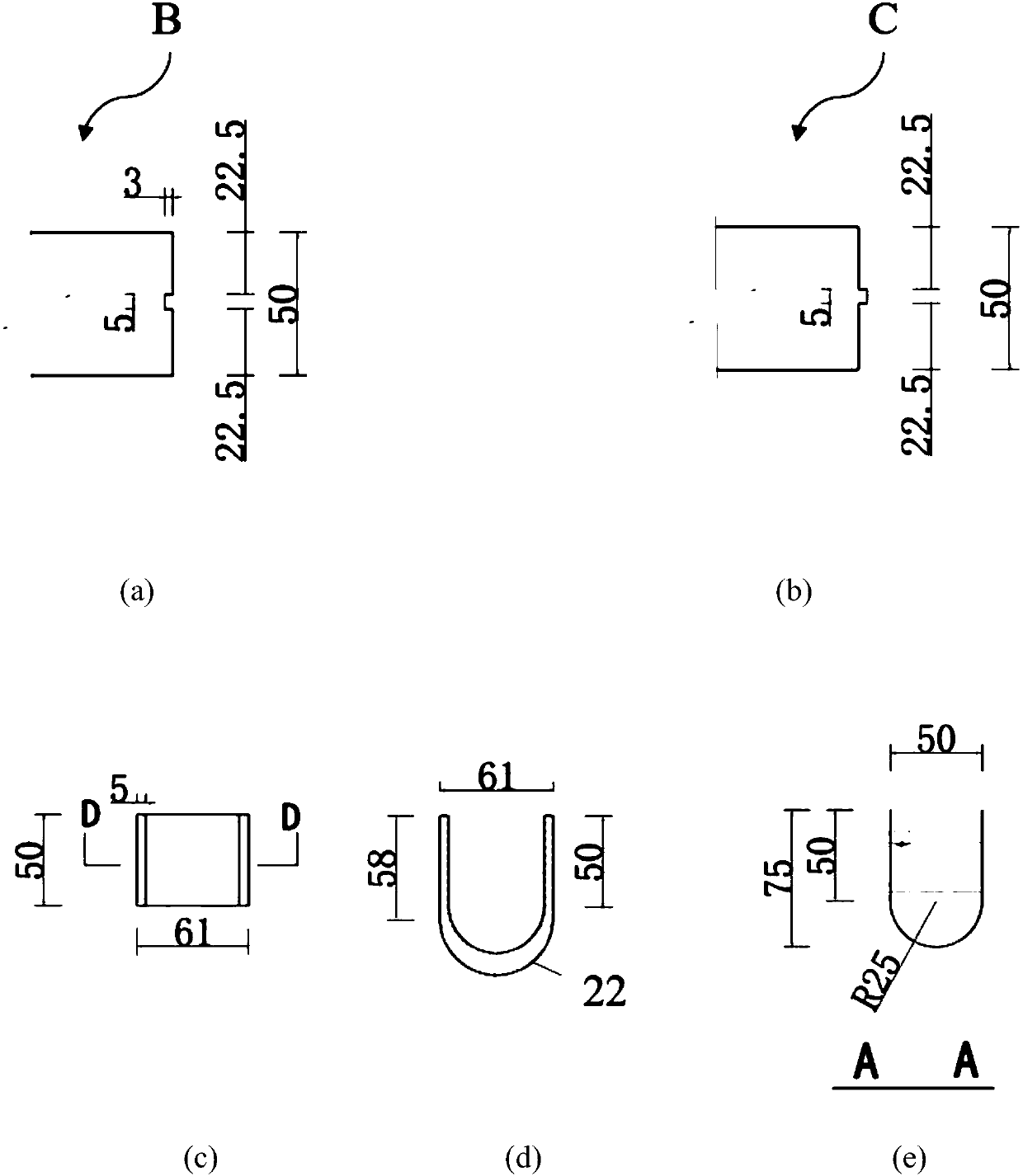

[0083] The slurry is introduced into the ring mold 20 and vibrated while loading. The whole process is com...

Embodiment 3

[0095] In Example 3, the method of the present invention is used to evaluate the anti-soft water erosion ability of a composite cement used as a composite cementitious material in an environment of 28.6 ° C after high-mixing fly ash and stone powder:

[0096] Step 1. Slurry preparation and loading:

[0097] Take about 5000g of composite gelling material and pour it on a metal tray, spread it gently with a scraper, then place it in an electric blast drying oven, and dry it at a temperature of 105°C for 48 hours until it is weighed repeatedly at the end. The fluctuation of slag cement quality is around 1.2%.

[0098] 600g was accurately weighed from the fully dried composite gelled material as a sample for testing. Accurately weigh 270g of deionized water according to 0.45 times the mass of the sample, and then make a slurry according to the method specified in "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Methods" (GB / T 1346-2011).

[0099] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance coefficient | aaaaa | aaaaa |

| water resistance coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com