Slurry flow guide rod mechanism of solar silicon wafer fretsaw cutting machine

A technology for solar silicon wafers and saw cutting machines, which is applied to work accessories, fine work devices, stone processing equipment, etc. The effect of processing adaptability, saving slurry and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

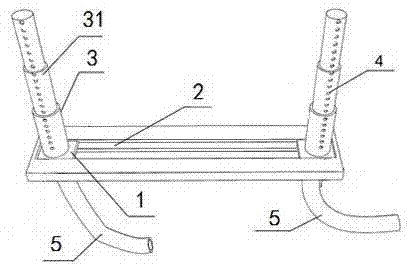

[0015] figure 1 As shown in the embodiment, a slurry guide rod mechanism for a solar silicon wafer wire saw cutting machine includes at least two guide rods, and is characterized in that each of the guide rods has a length telescopic mechanism.

[0016] Furthermore, the guide rod of the slurry guide rod mechanism of the solar silicon wafer wire saw cutting machine slides and cooperates with the slide rail 2 through the slider 1, and the slide rail 2 is perpendicular to the length direction of the guide rod.

[0017] To further explain this embodiment, the slurry guide rod mechanism of the current solar silicon wafer wire saw cutting machine is fixed on the workbench and cannot be stretched up and down and moved. For wire saw cutting machines, the length of silicon ingots is divided into many specifications. When cutting silicon wafers, it is necessary to adjust the appropriate winding width of the wire saw steel wire according to the length of the silicon ingot. The length o...

Embodiment 2

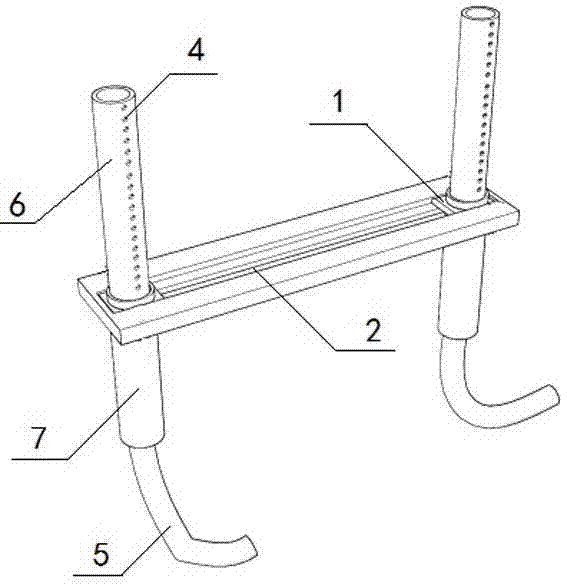

[0021] The difference between this embodiment and Embodiment 1 is: the slurry guide rod mechanism of the solar silicon wafer wire saw cutting machine, the length telescopic mechanism includes a fixed tube 6, a sliding tube 7, and a hose 5, and the fixed tube 6 The inner end and the hose 5 are socketed and fixed on the slider 1; the outer end of the sliding tube 7 is sealed; the lower part of the sliding tube 7 is inserted into the fixing tube 6, and is slidably matched and sealed with the sliding tube 7; A row of holes 4 is provided.

[0022] Further explanation of this embodiment: Different from Embodiment 1, the length telescopic mechanism of this embodiment is not formed by sliding and socketing a plurality of sleeve pipes 31 , but is composed of a sliding fit between the fixed pipe 6 and the sliding pipe 7 . The fixed pipe 6 is fixed on the slider 1, and the length of the guide rod is only adjusted by extending and withdrawing the slide pipe 7, thus avoiding the instabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com