Multifunctional cement pouring device

A multi-functional cement technology, which is applied in construction, building structure, and building material processing, can solve problems such as inability to form large-scale production, quantification, and slow speed, so as to ensure pouring quality, save slurry, and operate Labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

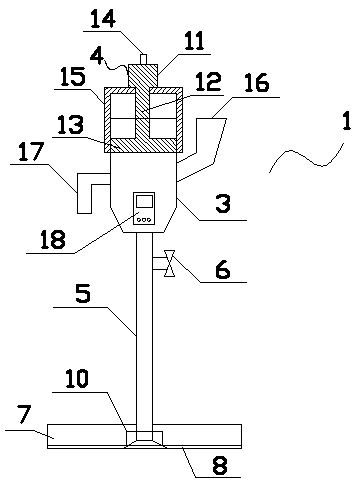

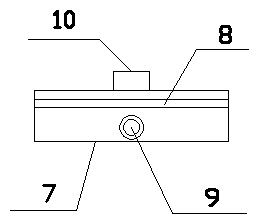

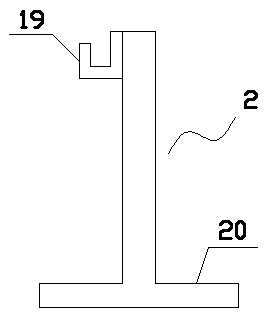

[0017] Such as figure 1 , figure 2 and image 3 As shown, a multifunctional cement pouring device includes a pouring device 1 and a support frame 2, the pouring device 1 includes a pouring part and a leveling part, the pouring part includes a storage tank 3 and a pressure pump 4, and the storage tank 4 It is an inverted cone with a large upper opening and a small lower opening. A discharge pipe 5 is welded at the lower opening of the storage tank 4. A control valve 6 is installed on the discharge pipe 5, and a lower end of the discharge pipe 5 is fitted with a Profile beam 7, profile beam 7 is perpendicular to discharge pipe 5, and arc beam 8 consistent with the length of profile beam 7 is installed at the bottom of profile beam 7, described discharge pipe 5 runs through profile beam 7, and discharge pipe 5 The discharge port 9 at the lower end is flush with the bottom surface of the shaped beam 7 .

[0018] Wherein, a vibrator 10 is installed at the middle part of the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com