Cross joint grouting pipeline of concrete arch dam or gravity-type arch dam and manufacturing method of cross joint grouting pipeline

A production method and concrete technology, which are applied to arch dams, dams, ceramic forming cores, etc., can solve the problems of the slurry outlet of the grouting pipe being not easily blocked and the slurry outlet of the grouting pipe being easily blocked, so as to reduce the number of grouting pipelines. The effect of layout, material saving and smooth pulping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

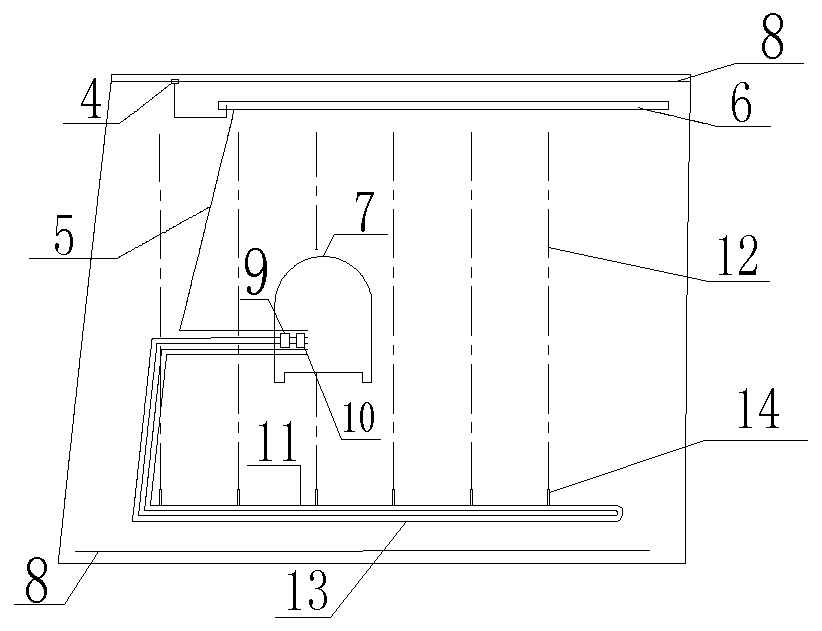

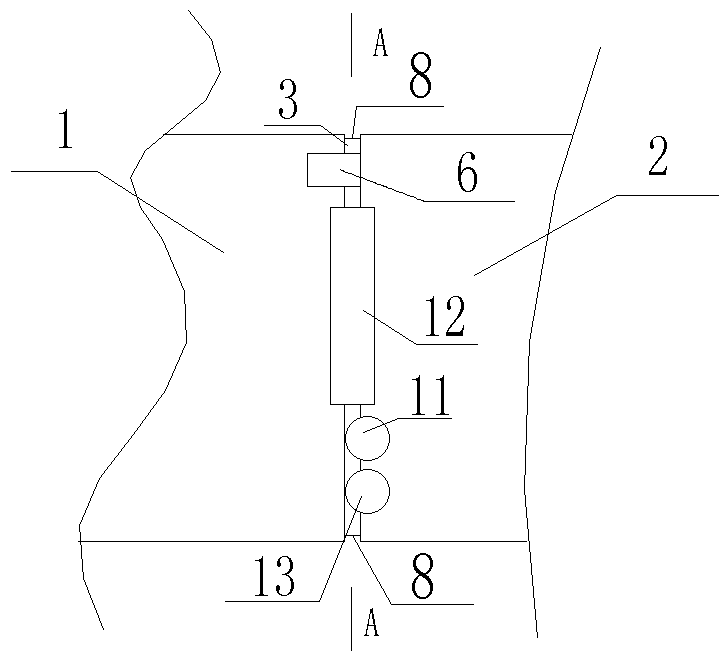

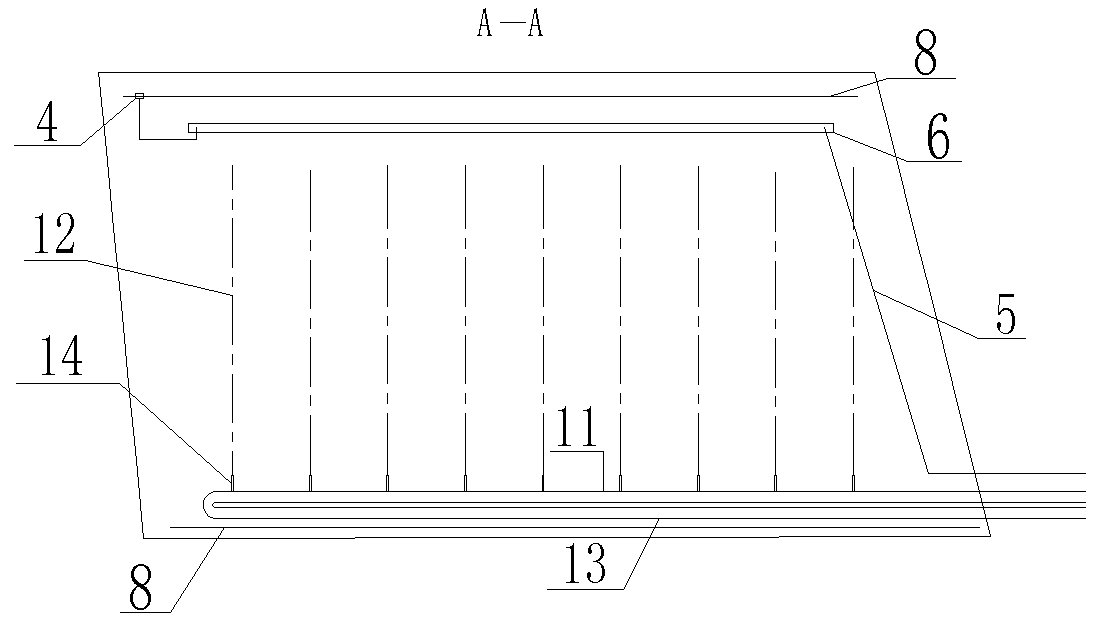

[0033] The present invention will be described in detail below in conjunction with the drawings. The enumerated embodiments can enable those skilled in the art to better understand the present invention, but do not limit the present invention in any form.

[0034] Such as Figure 1-5 As shown, a transverse joint grouting pipeline of a concrete arch dam or a gravity arch dam is improved on the basis of the existing concrete dam transverse joint grouting technology, retaining the grout inlet pipe 11, the grout return pipe 13 and the grouting pipes required for grouting. Exhaust pipe 5, exhaust groove 6, exhaust pulp box 4 and spare pipeline etc. The standby pipeline is the same group of grout inlet and return pipes as the main grouting pipeline. Since the inlet and return grout pipes are buried in the concrete, one more set should be buried to ensure the smooth progress of the construction. The slurry inlet pipe, the slurry return pipe and the spare pipeline are arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com