Dam concrete template structure

A formwork and dam technology, which is applied to formwork/formwork components, building structures, and on-site preparation of building components, can solve problems such as difficult construction, easy formation of construction gaps, and easy water leakage, etc., to reduce construction difficulty , Easy to install surface formwork, to avoid the effect of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

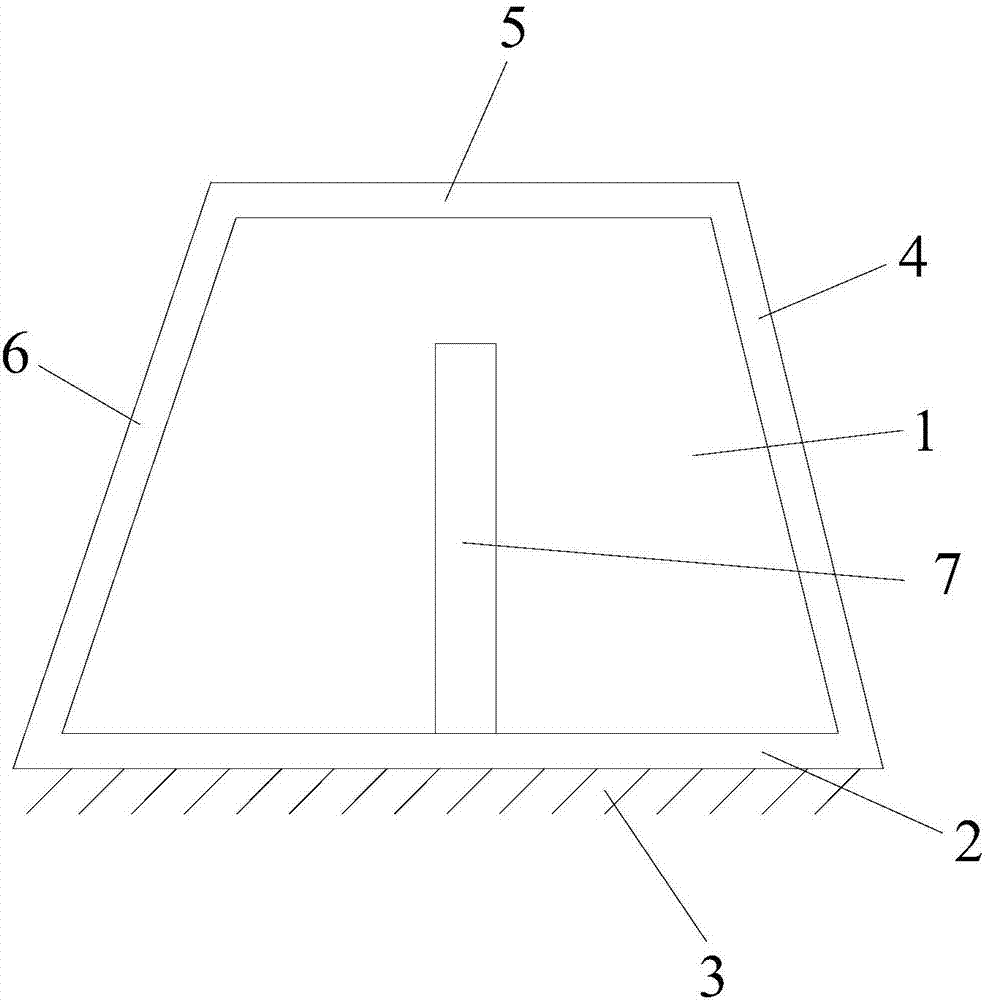

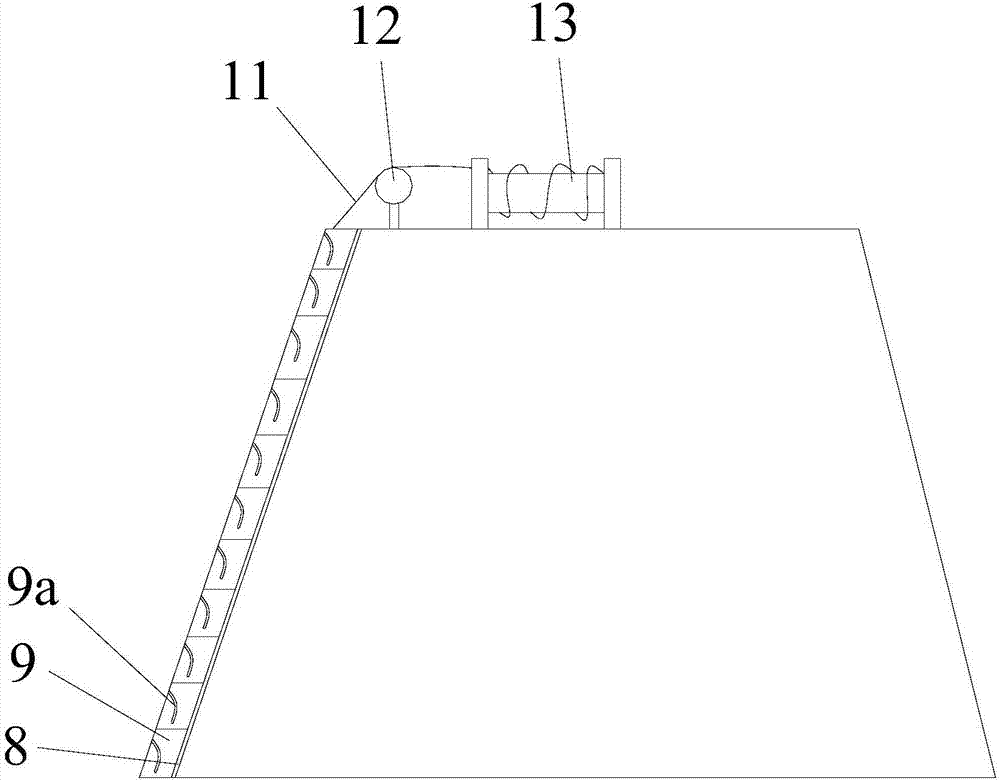

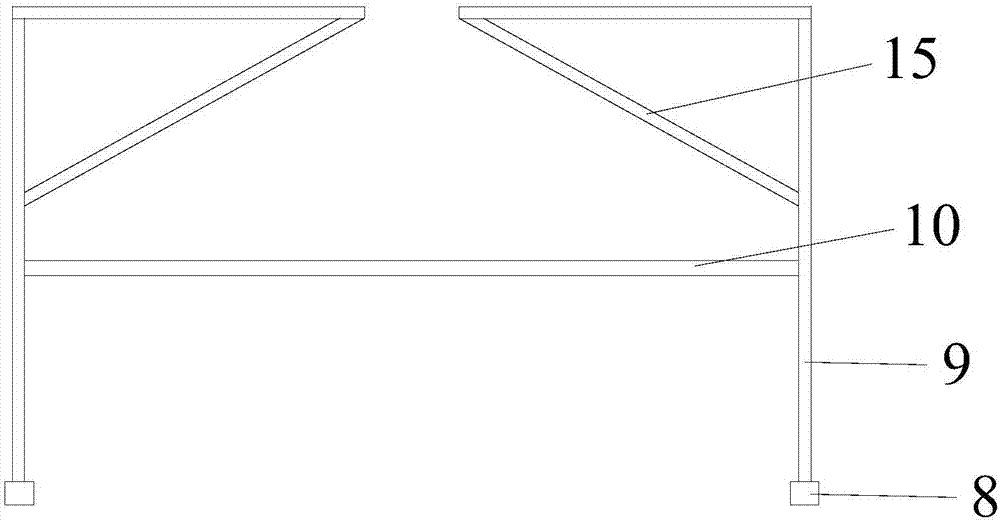

[0017] Please refer to Figure 1-3 , the dam concrete formwork structure comprises a dam body 1, a dam cushion 2 at the bottom of the dam body 1, the underside of the dam cushion 2 is a dam foundation 3, and the downstream side of the dam body 1 is a dam side shell 4, and the dam side shell 4 extends to the top of the dam body 1 to form the crest shell 5, the upstream side of the dam body 1 is a slope 6, and the end of the dam body 1 is an inclined core wall 7, and the surface of the slope 6 is provided with two parallel inclined rails 8. Two inclined rails 8 are arranged on the two opposite side edges of the slope 6. On each inclined rail 8, a plurality of steel formworks 9 spliced in sequence along the direction of the slope 6 are slided and laid. The steel formworks 9 on the two inclined rails 8 are one by one. Corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com