Table device for polishing electrode caps

An electrode cap and desktop technology, which is applied in the field of automatic grinding devices for electrode caps, can solve the problems of scalding the operator's hands, partial wear of the electrode cap, affecting normal use, etc. The effect of quality, convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

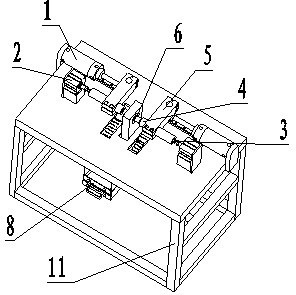

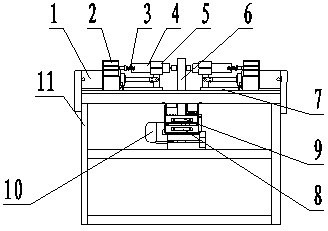

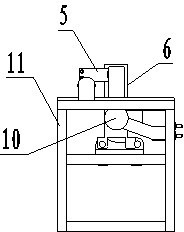

[0018] See Figure 1, Figure 2, image 3 , the present invention comprises motor and deceleration mechanism 10, grinding tool 6, electrode cap installation and propulsion mechanism, unloading mechanism, workbench 11 and electrical control system, described motor and deceleration mechanism 10 are installed under workbench 11 table tops, motor And the deceleration mechanism 10 is connected with the grinding tool 6. The grinding tool 6 is provided with two sets of blades supporting the grinding of the left and right electrode caps at the same time. It is located in the middle of the workbench 11 and floats axially. The installation of the electrode cap, the propulsion mechanism, and the discharge mechanism all include two symmetrical parts, and they are all installed on the table top of the workbench 11.

[0019] See Figure 1, figure 2 , image 3 , Figure 4 , the electrode cap installation and propulsion mechanism of the present invention comprises an electrode cap grinding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com