Numerically controlled inner tooth grinding head

A technology for grinding teeth and internal teeth, which is applied to gear teeth manufacturing tools, gear teeth manufacturing devices, gear teeth, etc. The rigidity of the head and the installation angle of the grinding wheel, the effect of reducing the load of the grinding head and improving the grinding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

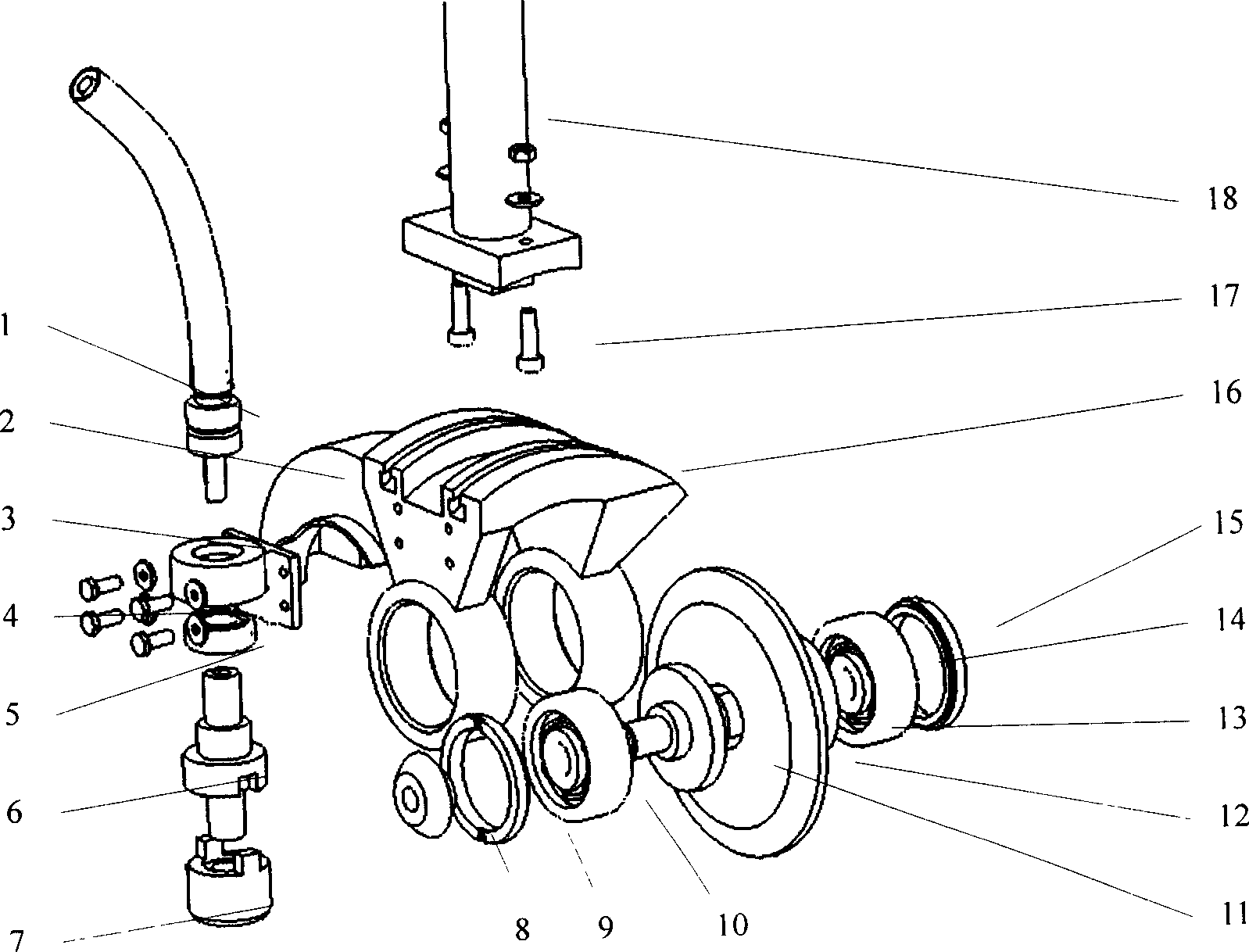

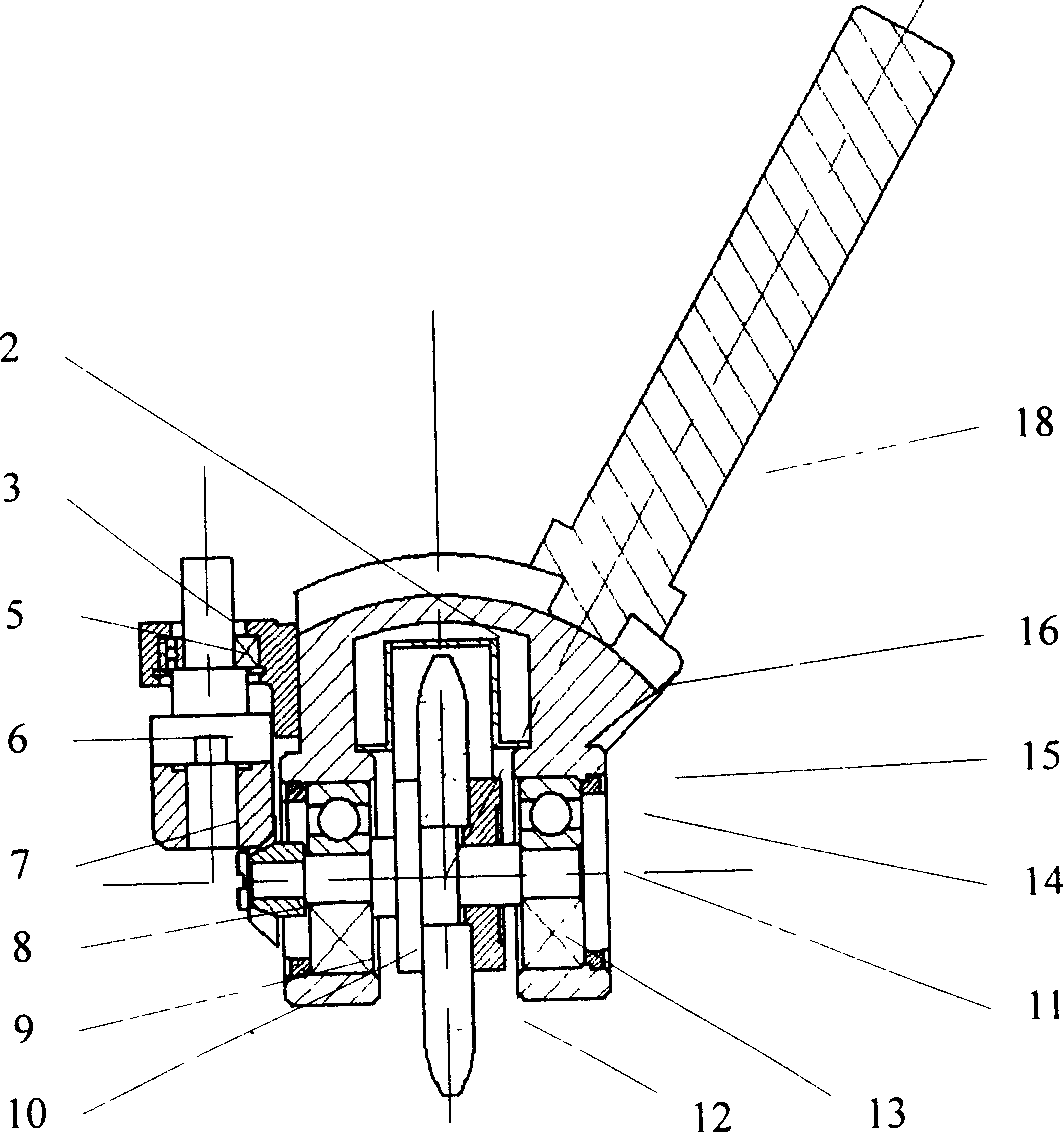

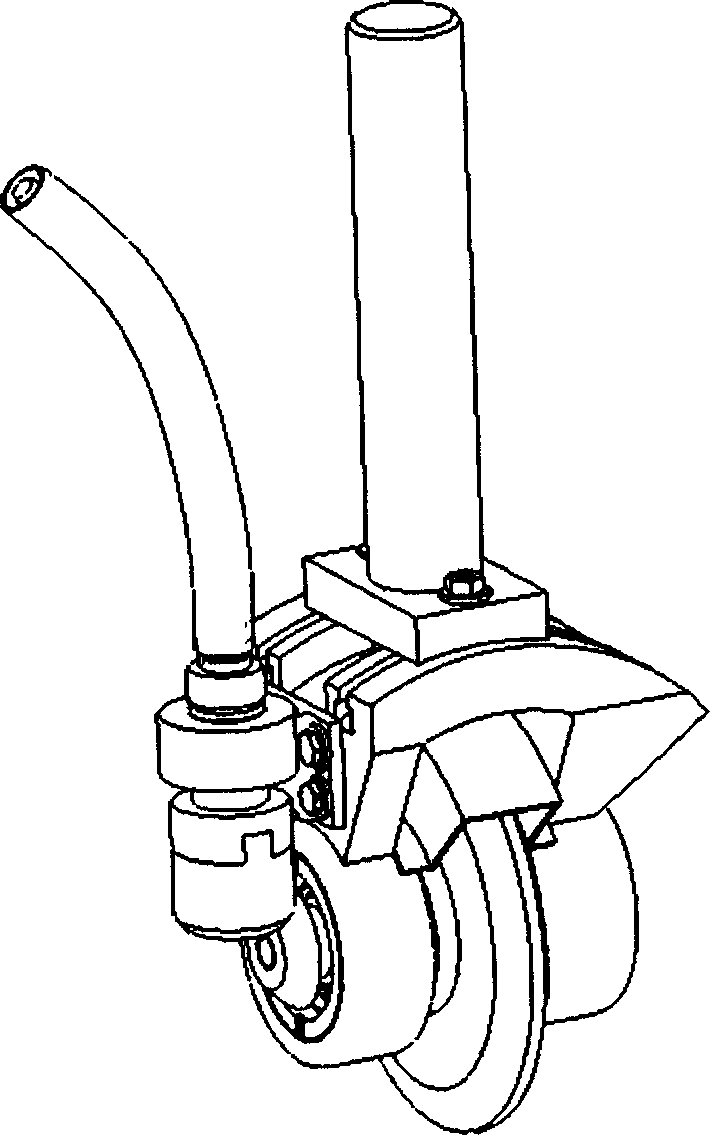

[0021] The present invention is described in further detail below in conjunction with embodiment and accompanying drawing, figure 1 ~ Fig. 4 shows the specific implementation structure of the present invention, but the embodiment of the present invention is not limited thereto.

[0022] Depend on figure 1 , 2 It can be seen that the special grinding head is composed of a cutter bar, a grinding wheel support mechanism, a grinding wheel installation angle adjustment mechanism and a power transmission mechanism.

[0023] The grinding wheel support mechanism is composed of a formed grinding wheel 12, a grinding wheel bracket 16, and a grinding wheel shaft assembly: a grinding wheel shaft 11, a grinding wheel clamping nut 13, a pair of precision bearings 10, 14, a pair of threaded end covers 9, 15 and a shield 2. The connection The relationship is as follows: the forming grinding wheel 12 is screwed on the grinding wheel shaft 11 by the grinding wheel clamping nut 13 . The grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com