Patents

Literature

30results about How to "Reduce grinding error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

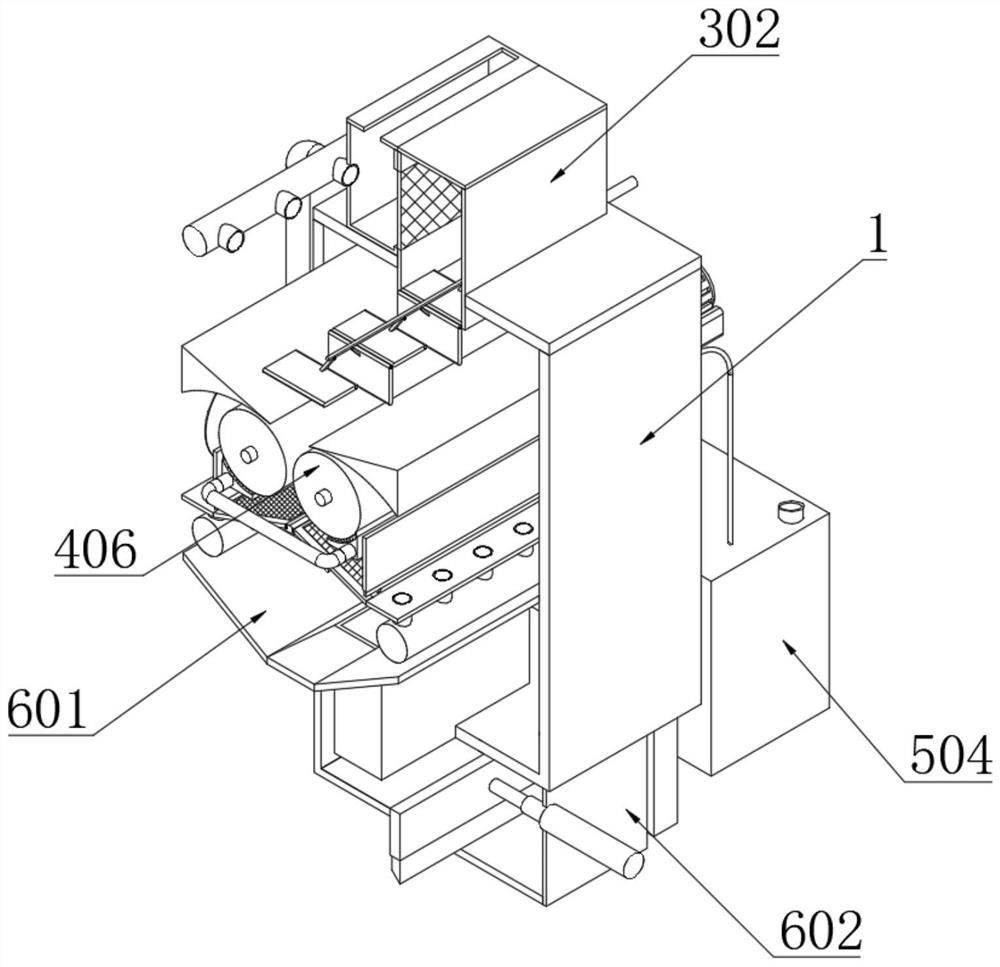

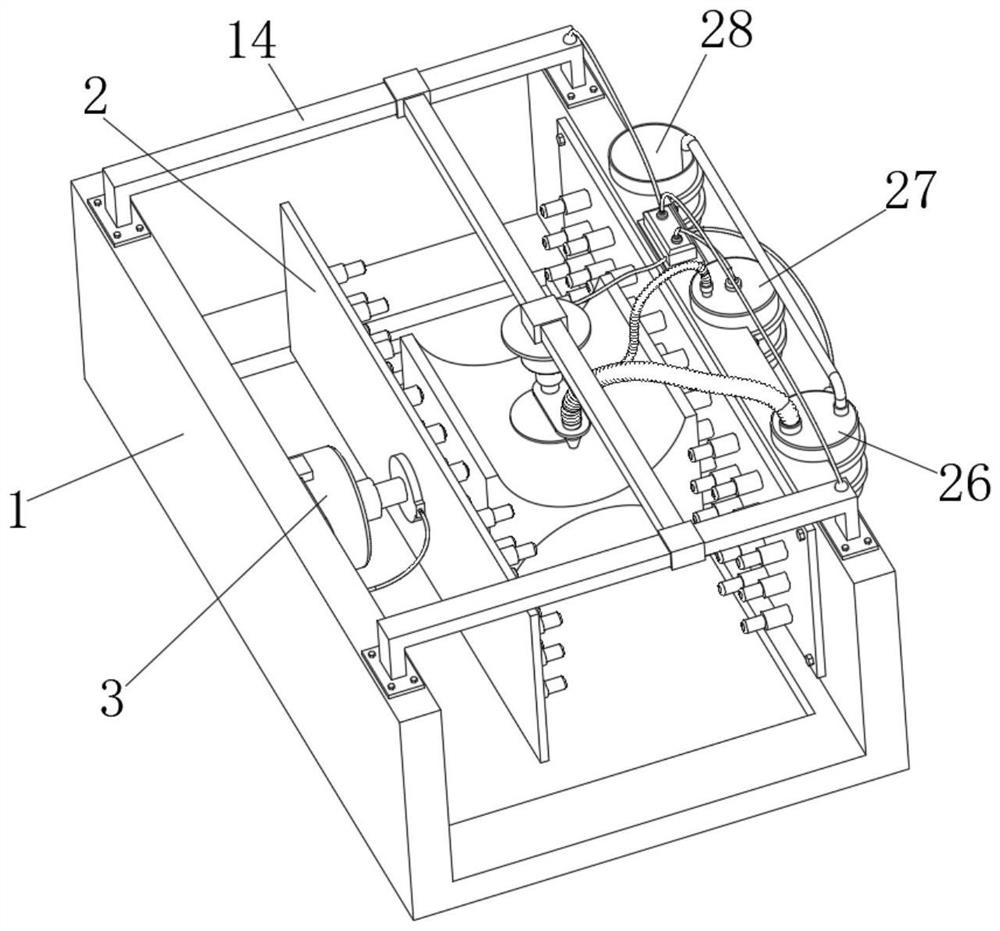

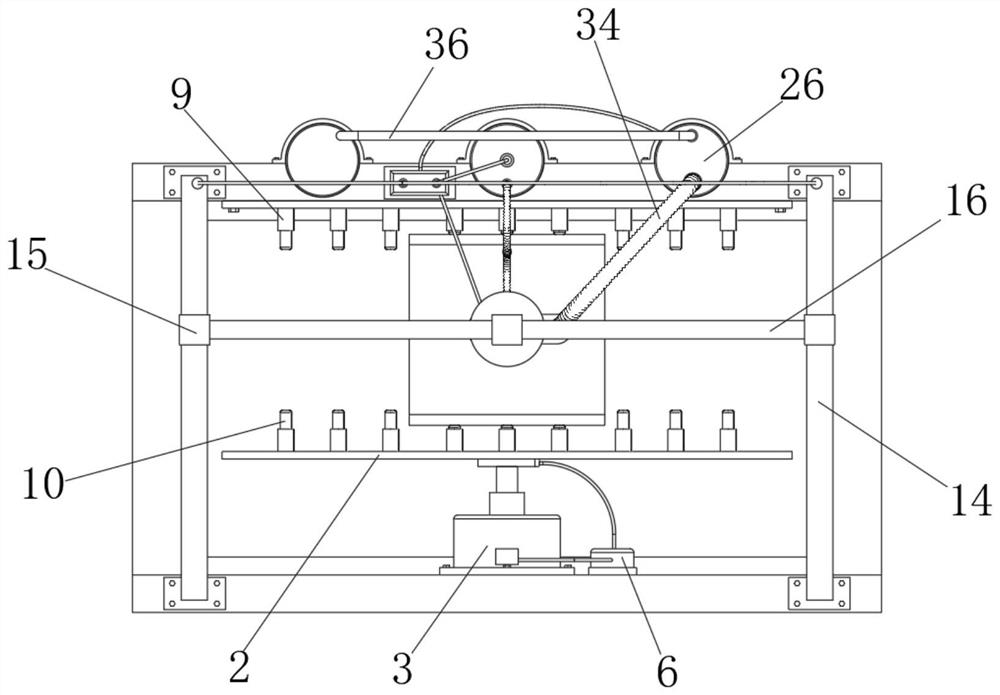

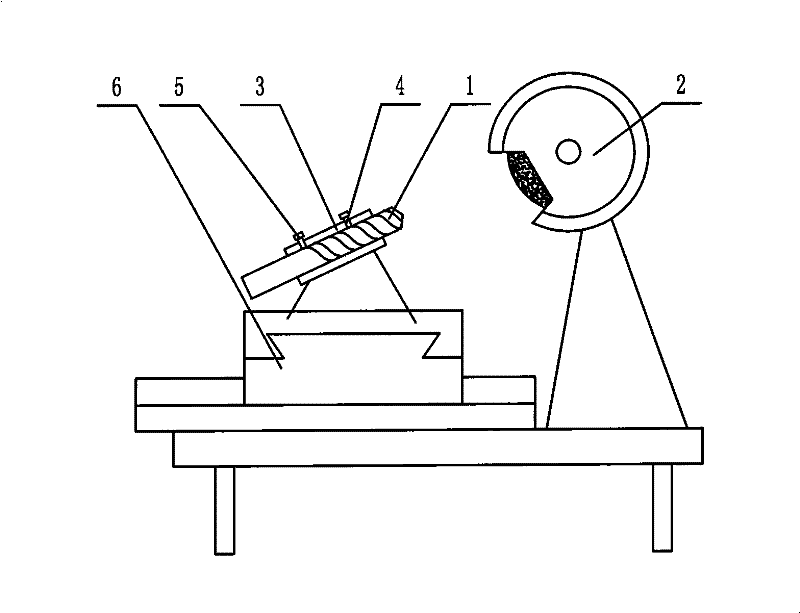

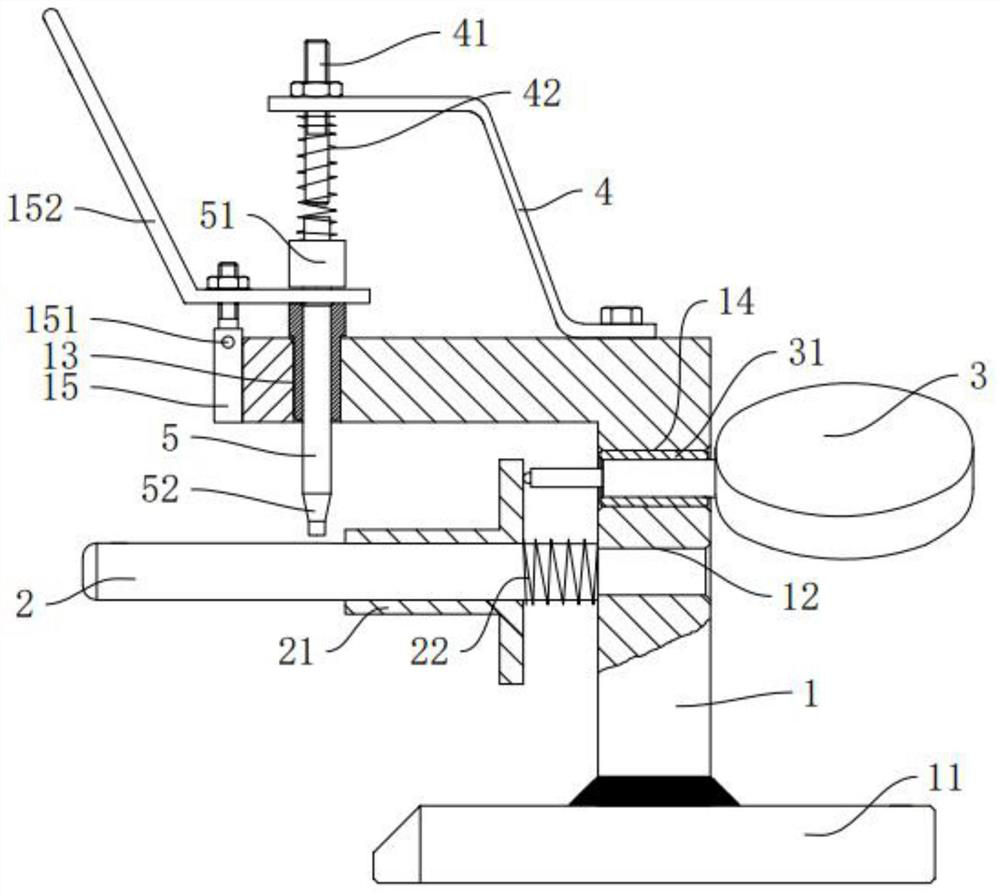

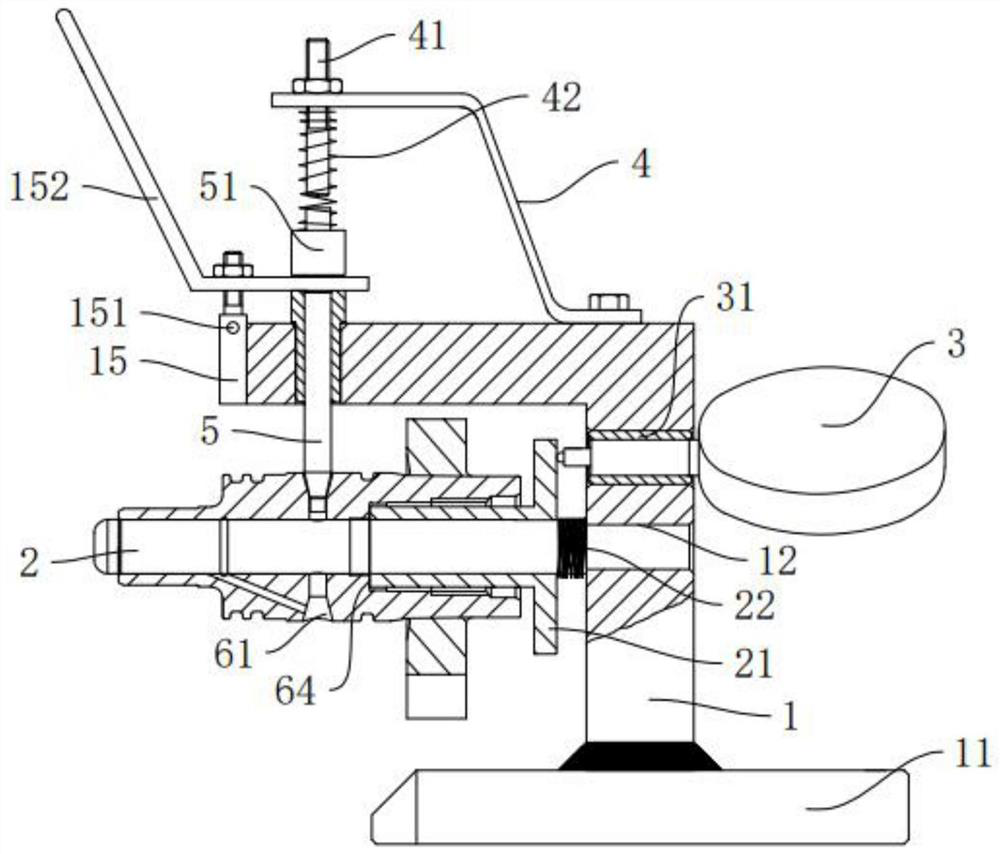

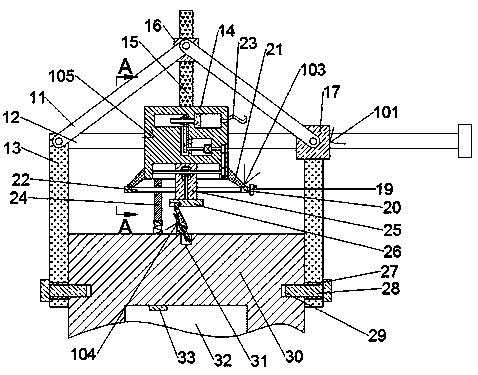

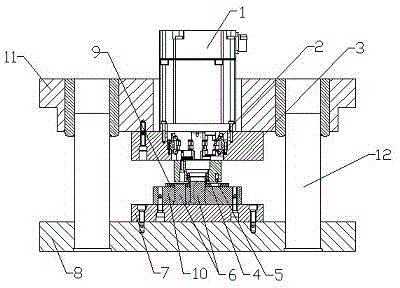

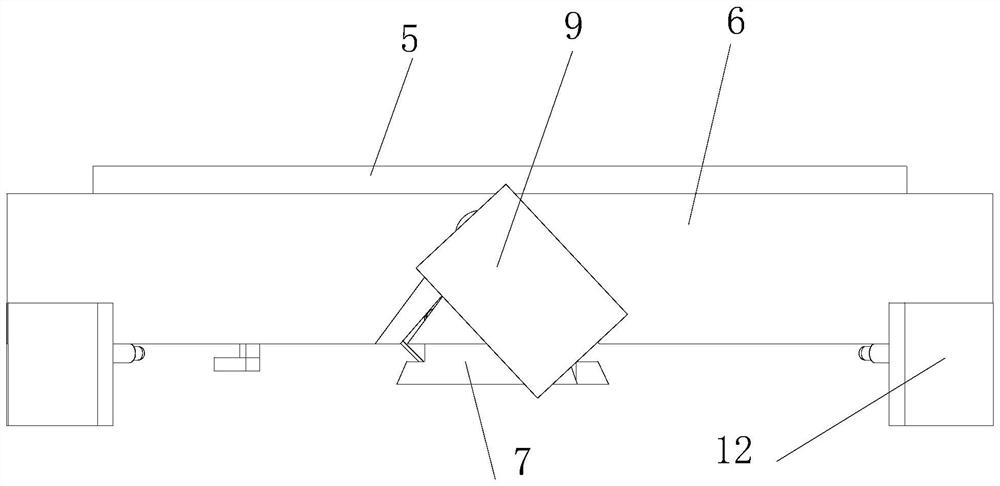

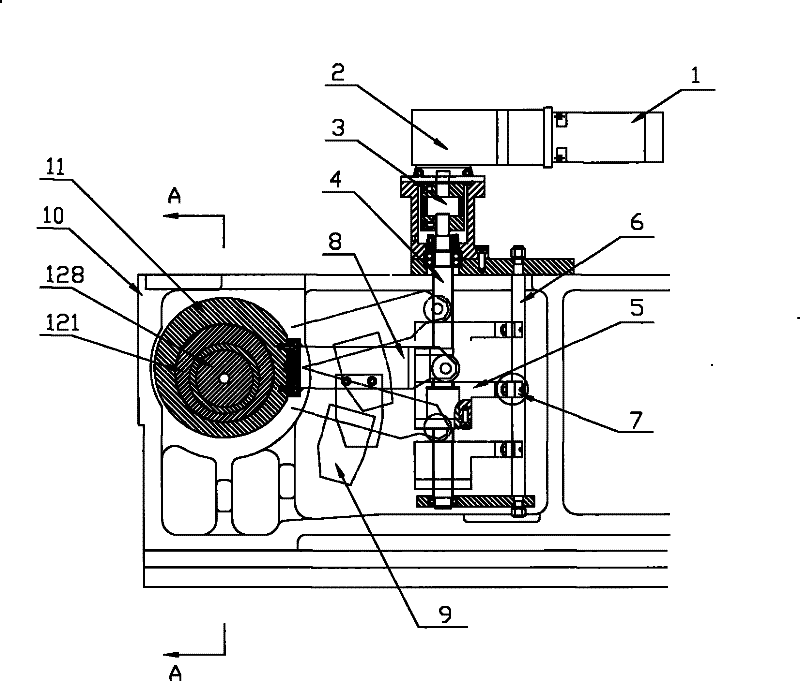

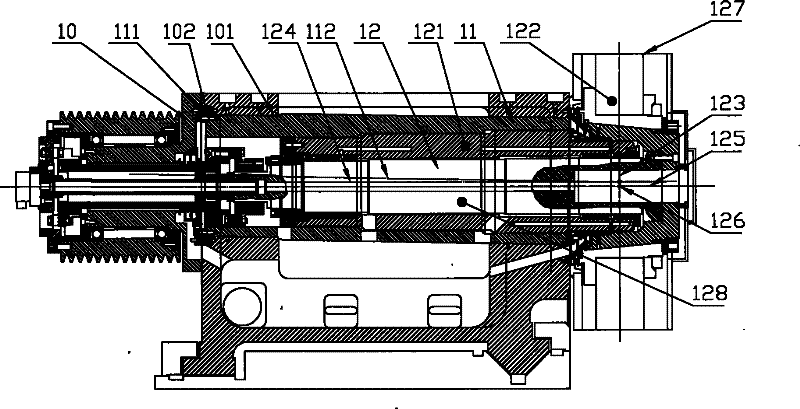

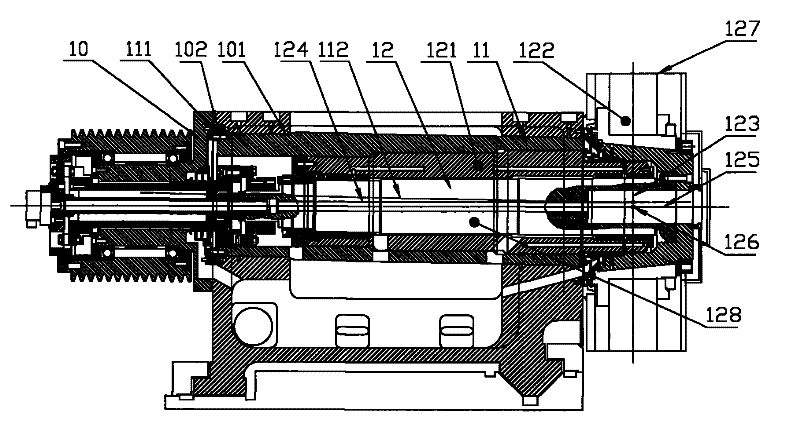

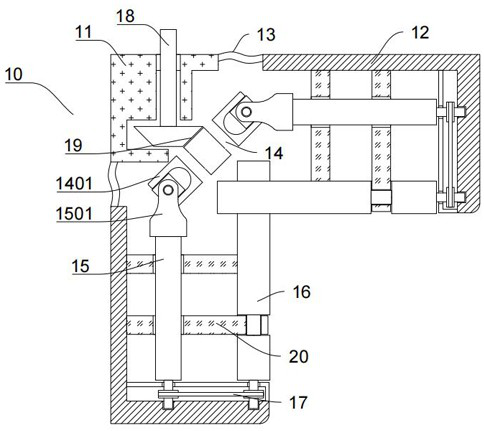

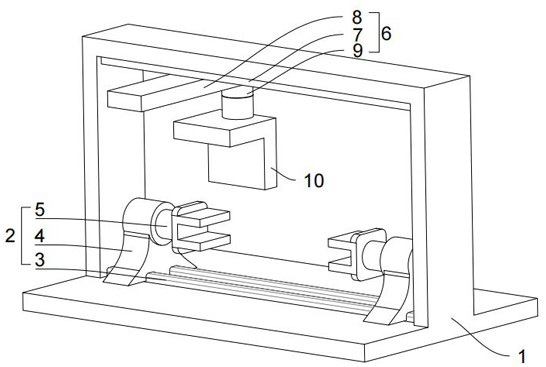

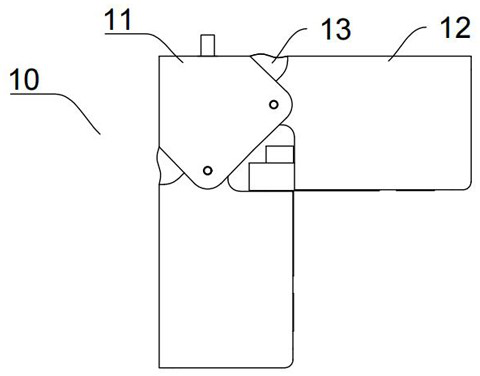

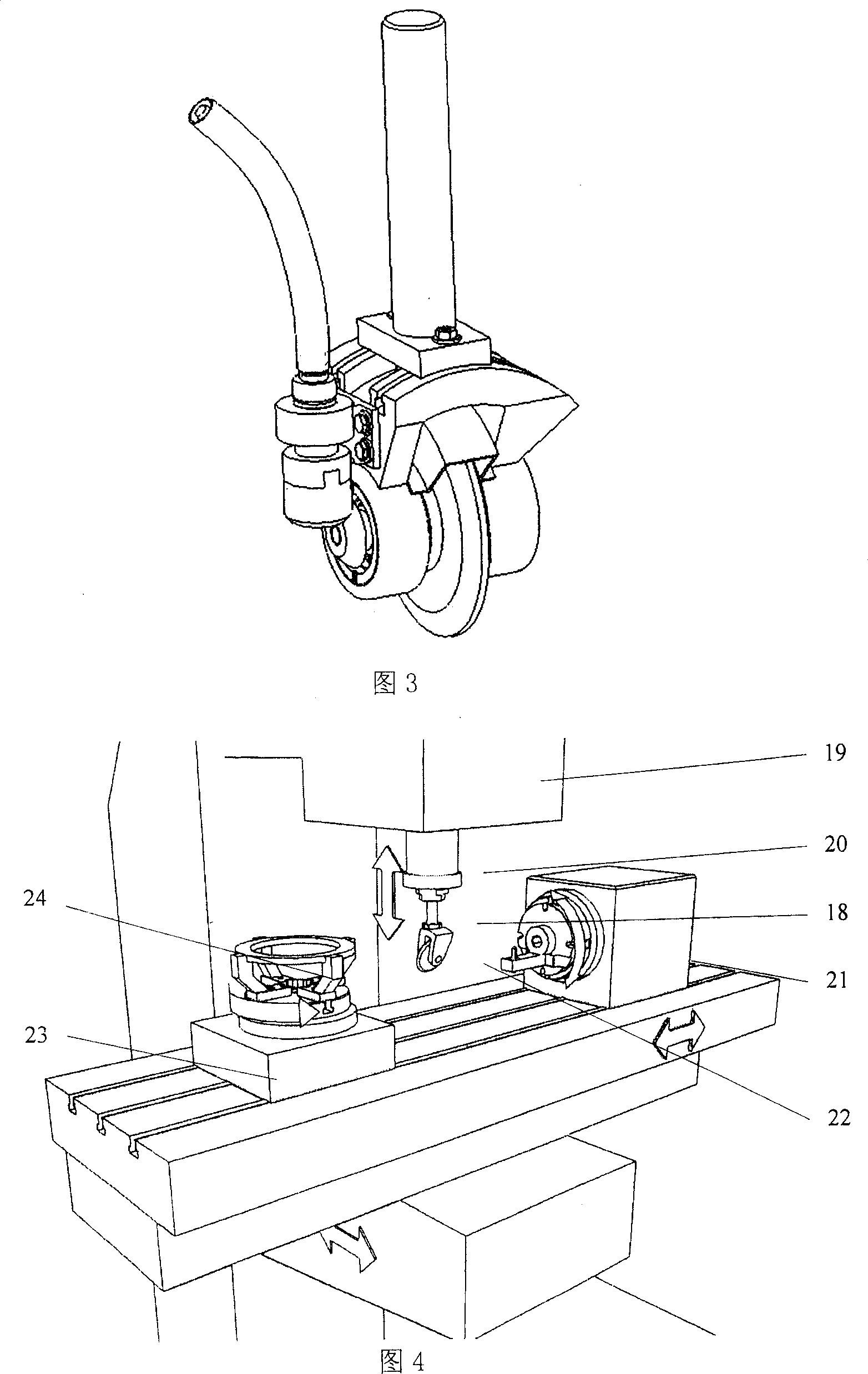

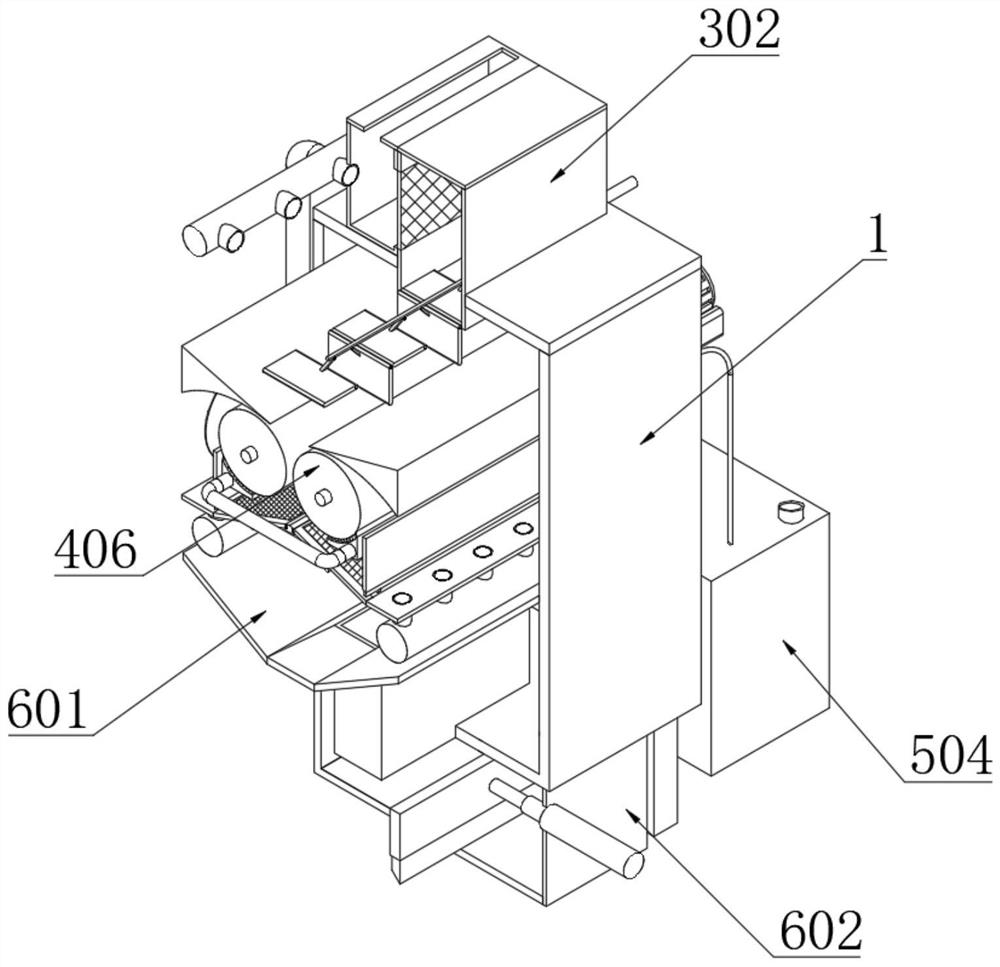

Numerical control drill double relief angle blade milling machine

ActiveCN101774137AReduce grinding errorCorrect shape exactlyTwist drillsNumerical controlMotor drive

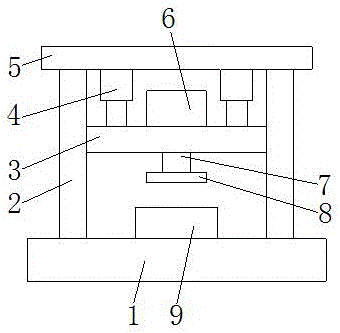

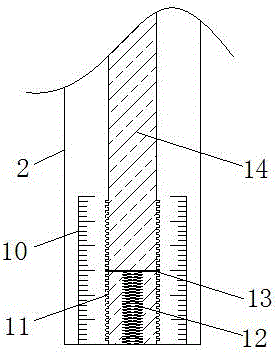

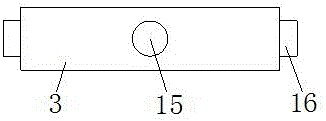

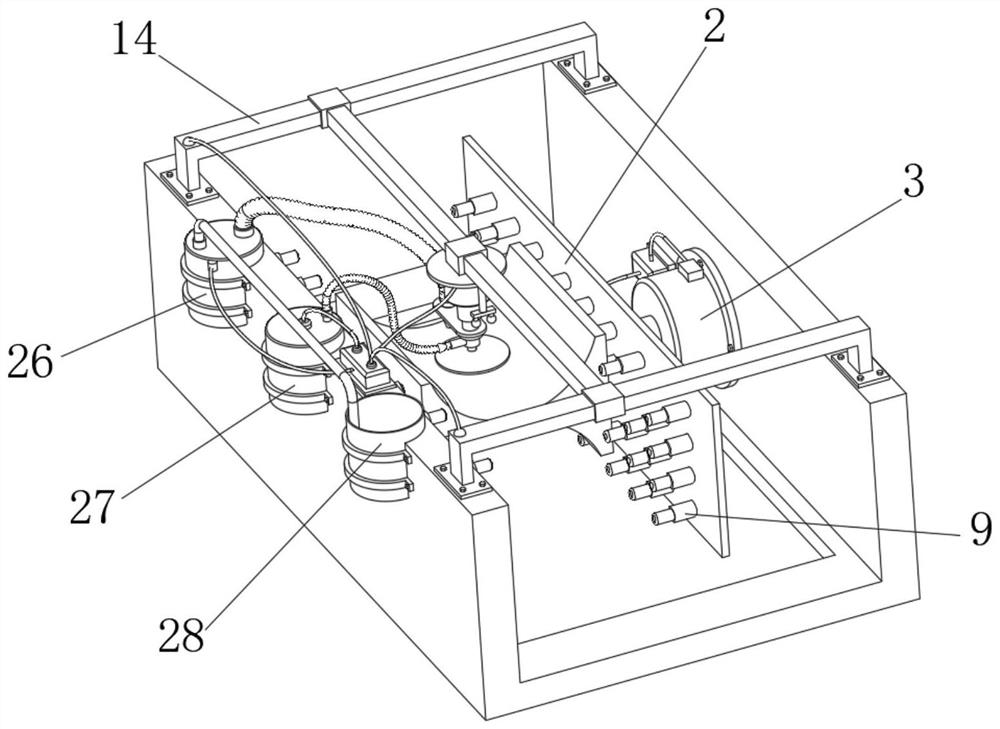

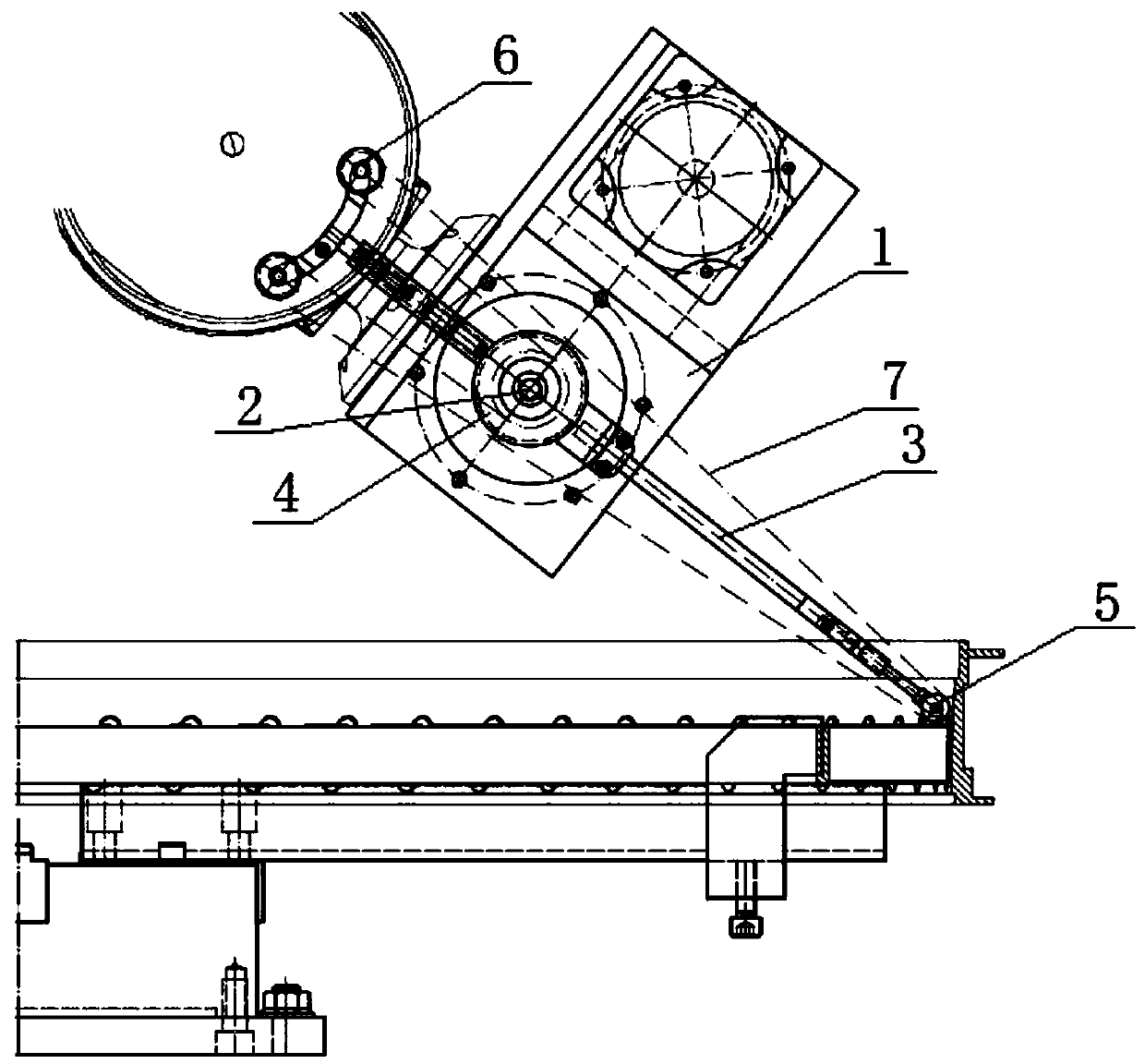

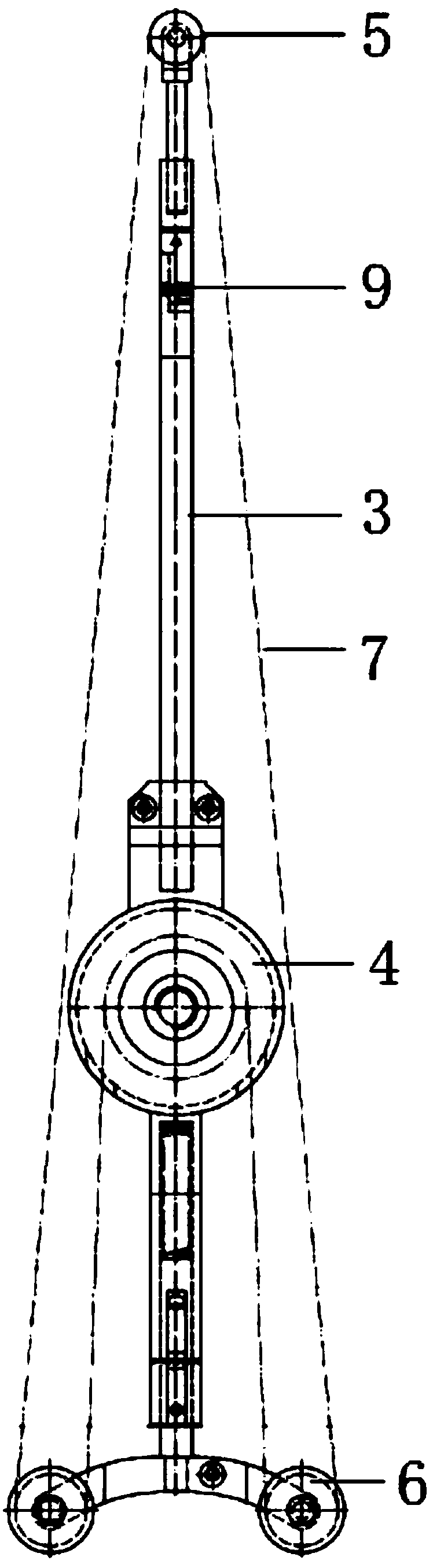

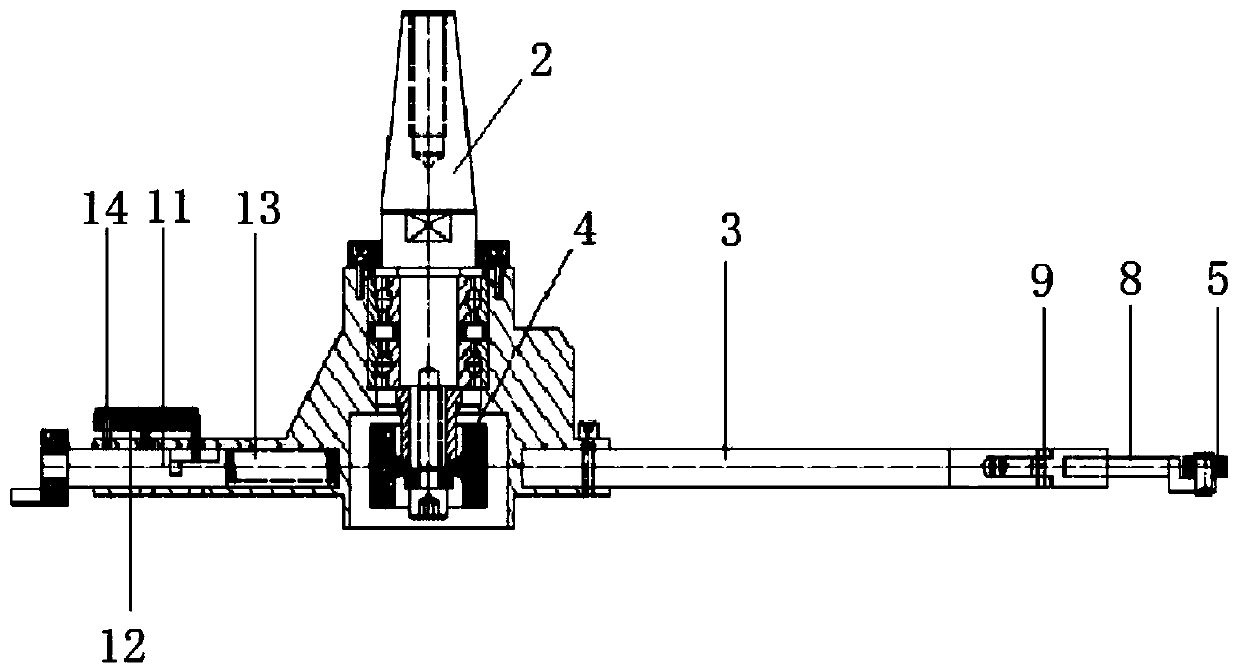

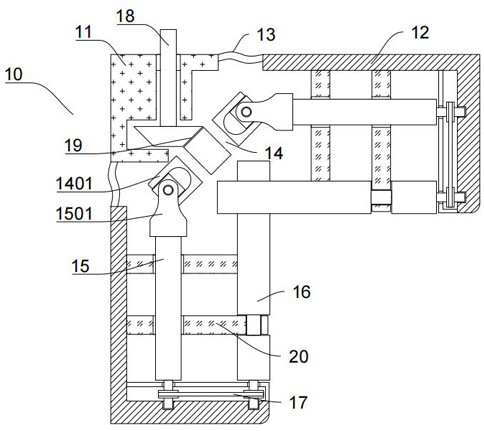

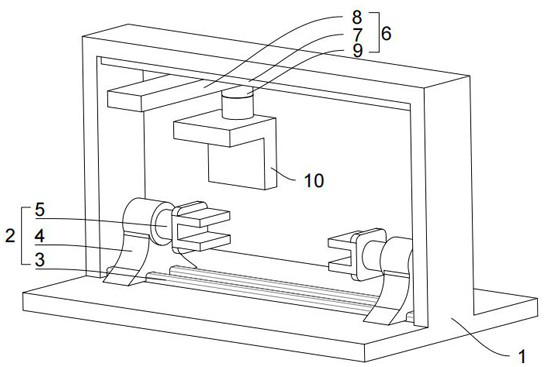

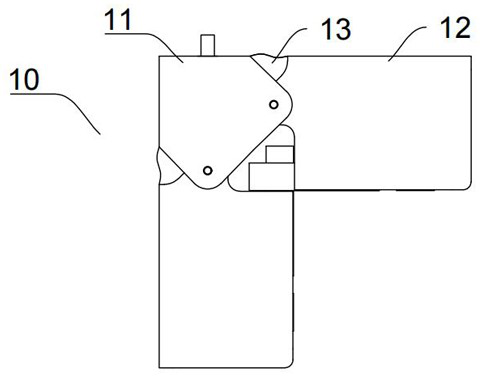

The invention relates to a numerical control machine device, in particular to a numerical control machine device carrying out grinding processing on a drill. The invention aims to provide a numerical control drill double relief angle blade milling machine. The device can carry out grinding processing on relief angles of the drills with different specifications and has high processing precision, high efficiency, good consistency and good safety. The numerical control drill double relief angle blade milling machine is provided with a stander, an electrical cabinet, a hydraulic device, an operation panel and a lubricating device. The stander is provided with a grinding wheel unit. The grinding wheel unit comprises a grinding wheel rack fixed on the stander, a grinding wheel in adjustable connection with the grinding wheel rack and a driving motor driving the grinding wheel to rotate. The grinding wheel rack is provided with a grinding wheel feeding device. The grinding wheel feeding device is provided with a grinding wheel feeding cylinder driving the grinding wheel to move. The front side of the grinding wheel rack on the stander is provided with an automatic loading device. The automatic loading device comprises a hopper storing processed components, a hopper cylinder driving the hopper, a trough for operating the components, a feeding rod and a feeding cylinder driving the feeding rod. A drill clamping device is arranged on the right side of the automatic loading device on the stander and comprises a chuck, a servo motor driving the chuck to rotate, a clamping cylinder and a brake cylinder. The lower part of the drill clamping device is provided with a chuck feeding device. The chuck feeding device comprises a guide rail which supports the drill clamping device and provides moving guide for the drill clamping device and a chuck feeding cylinder driving the drill clamping device to move.

Owner:NANJING CHENGUANG GRP

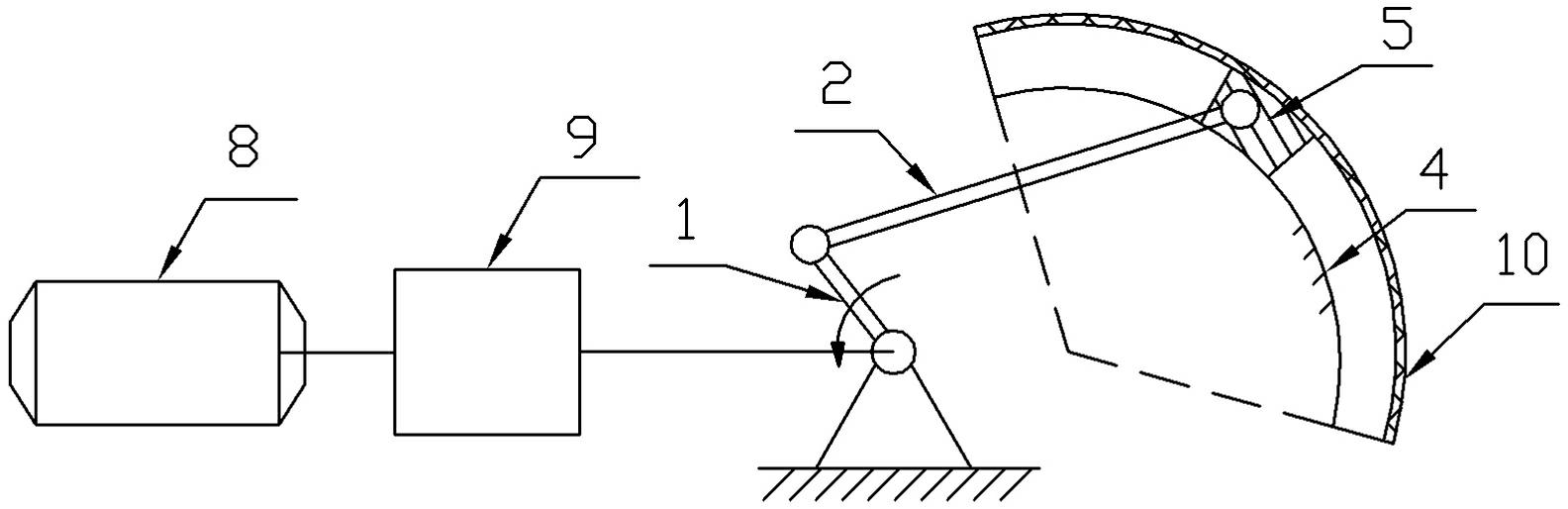

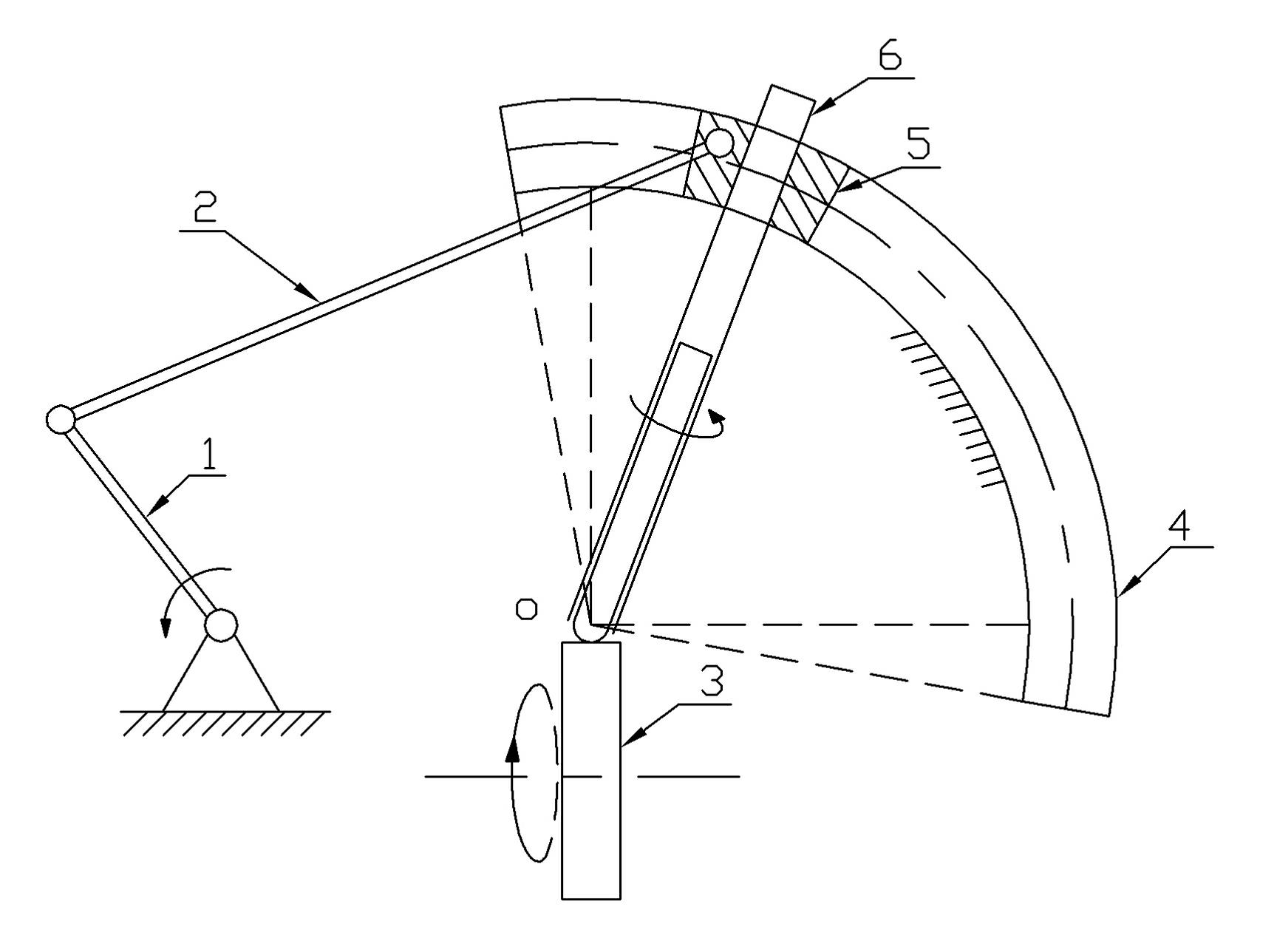

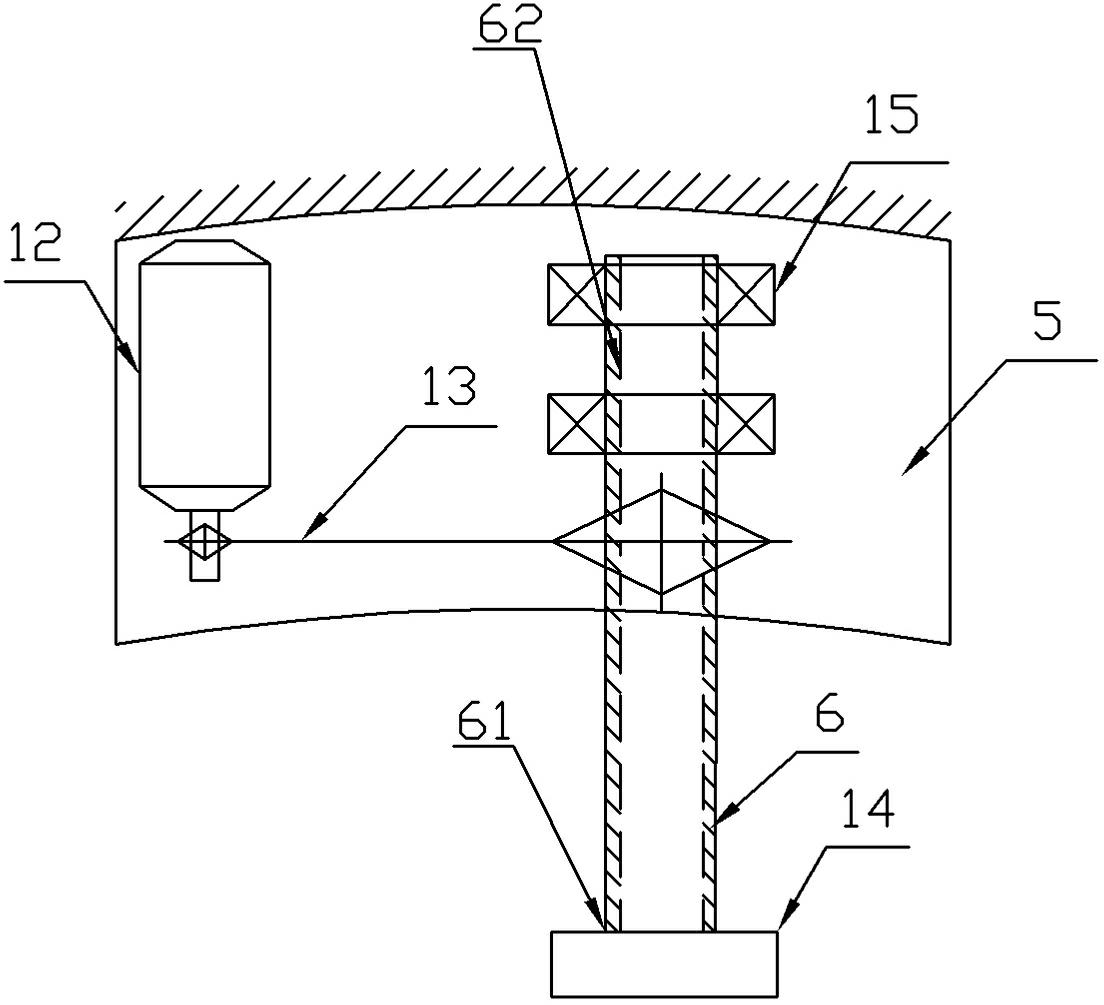

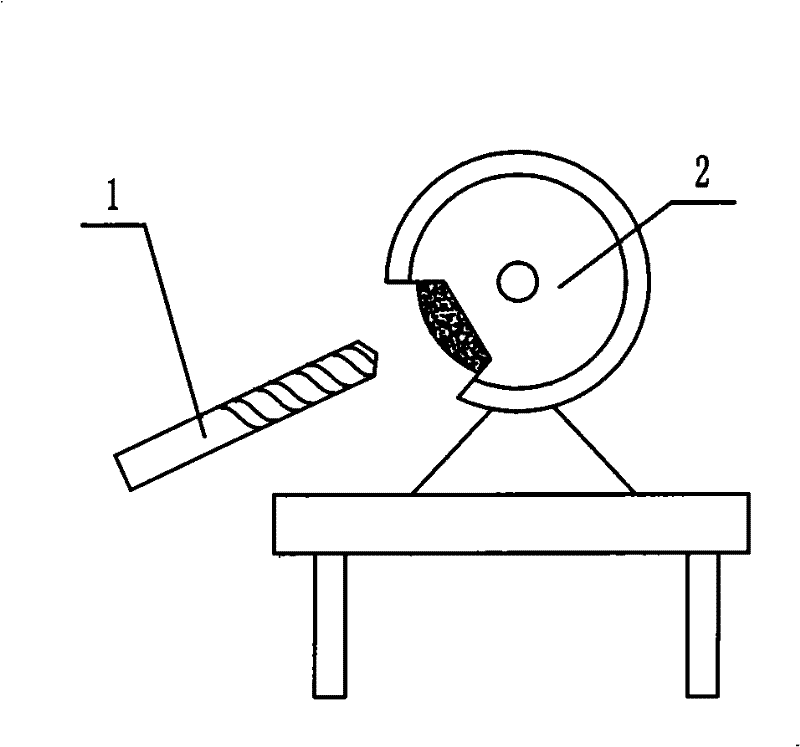

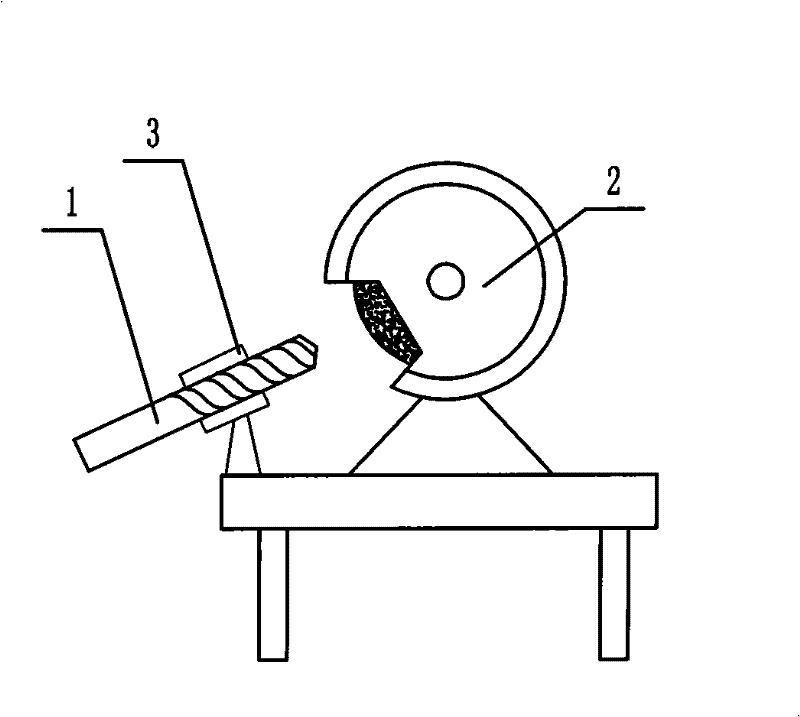

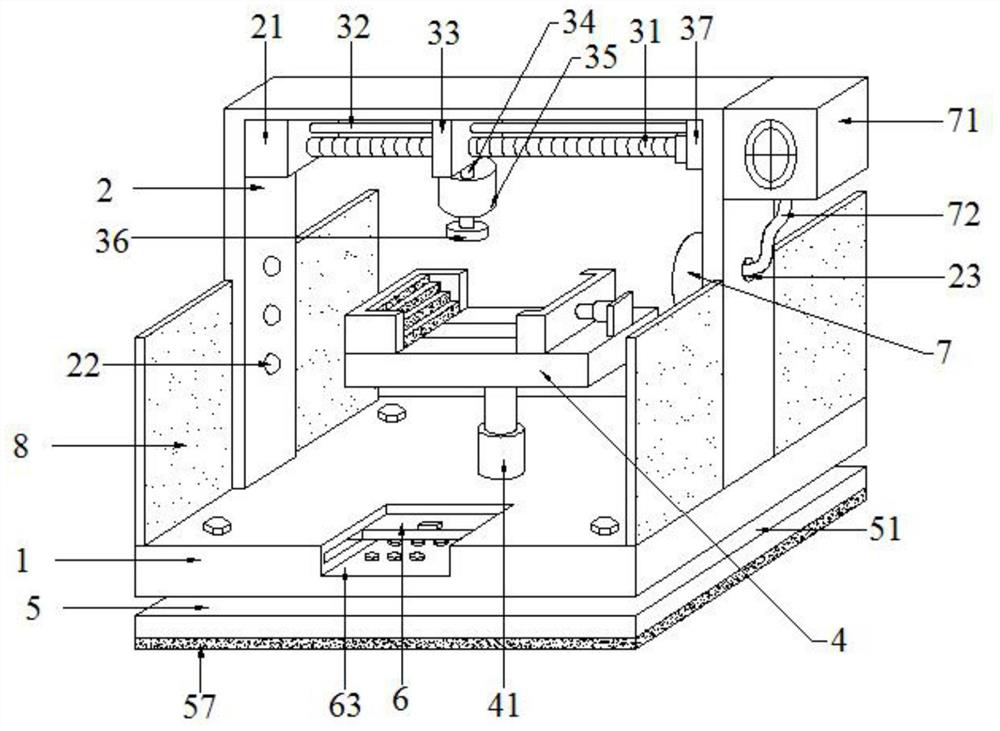

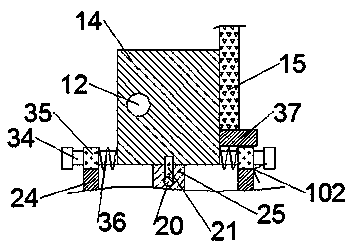

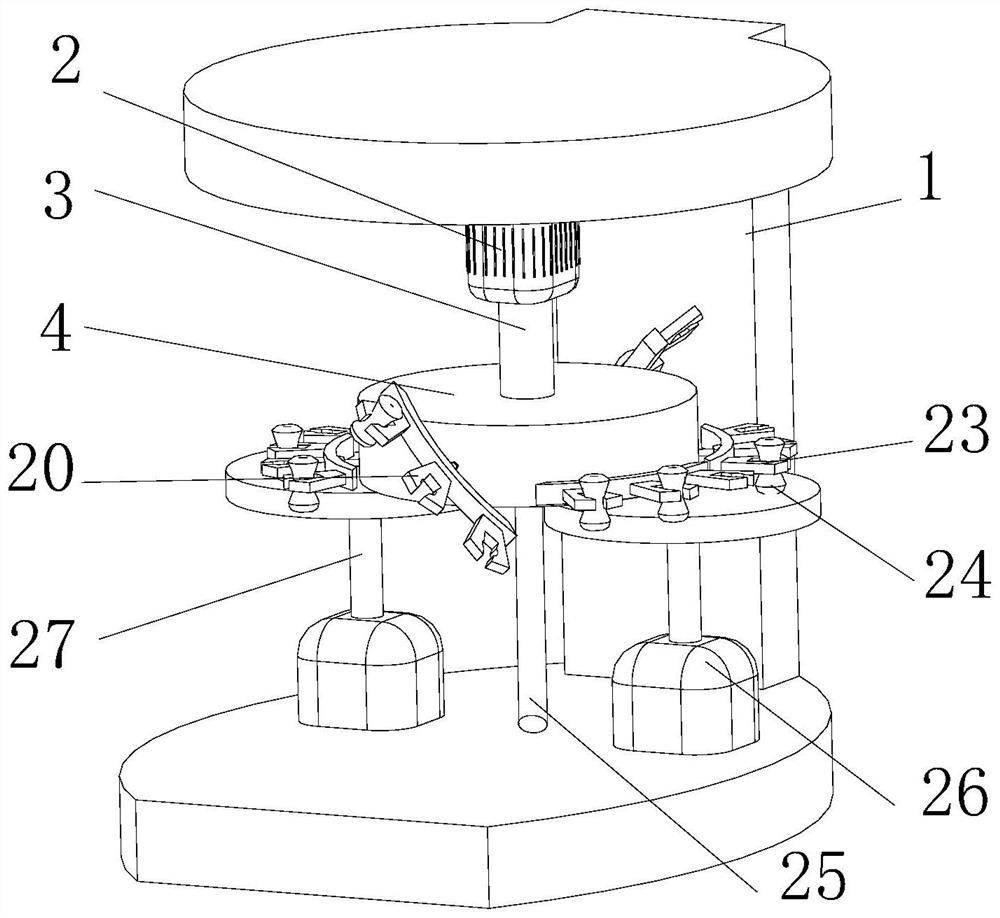

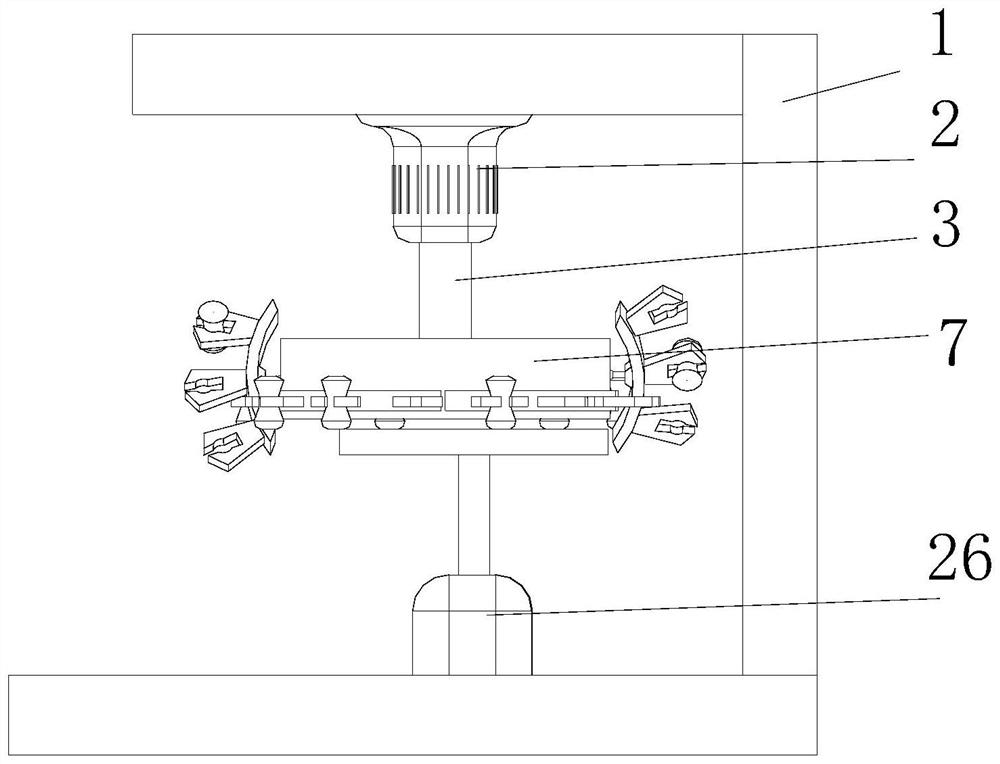

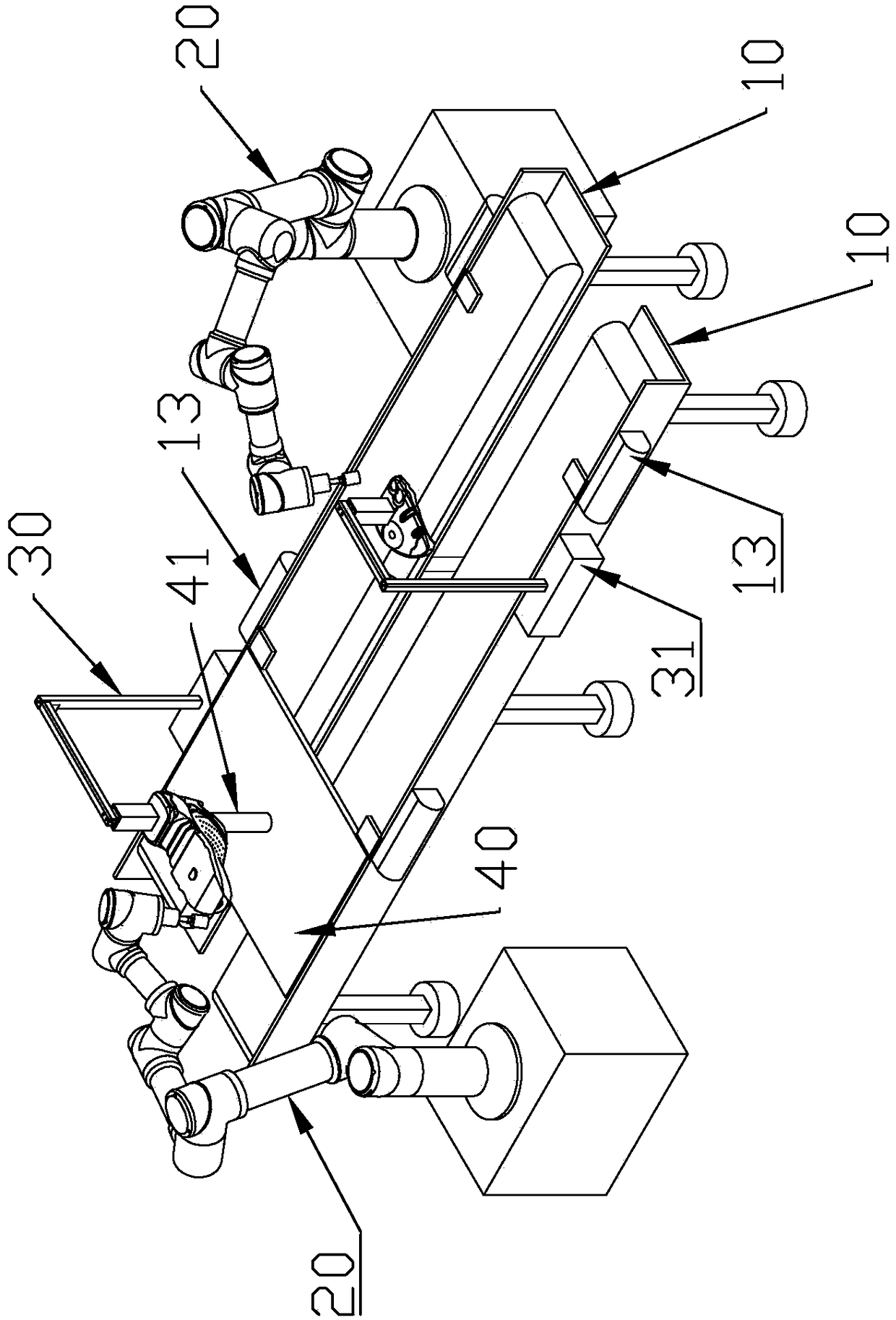

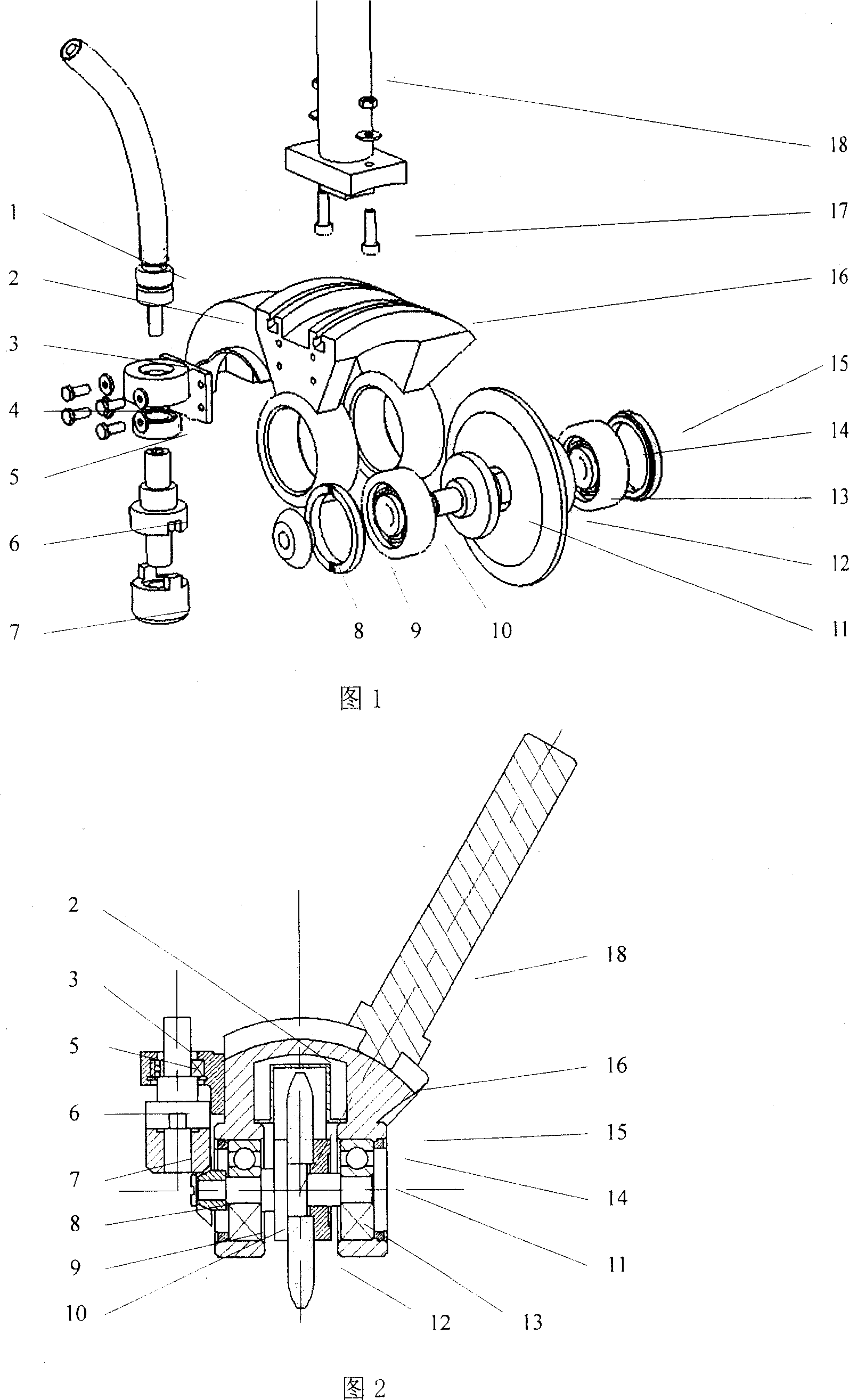

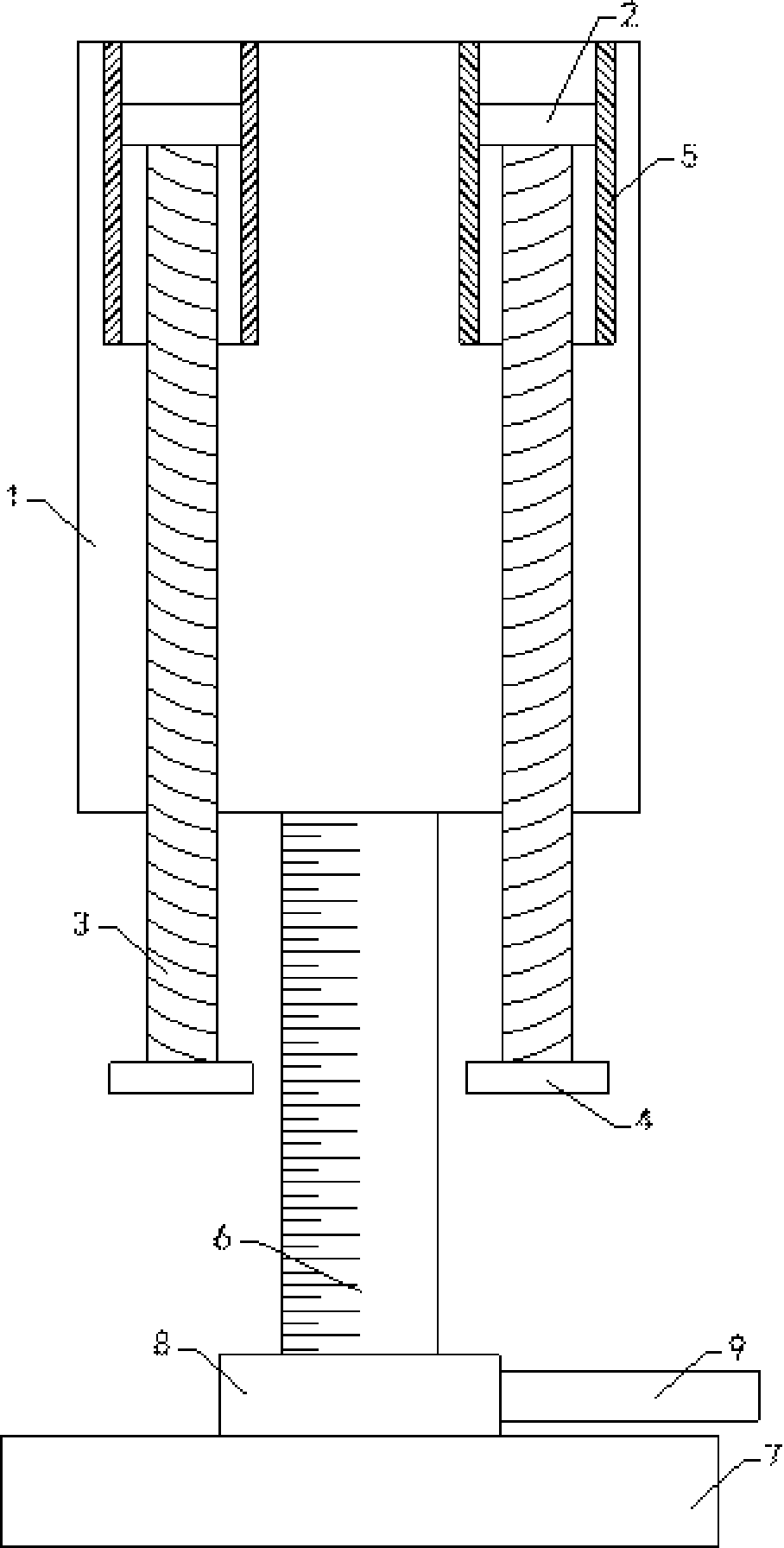

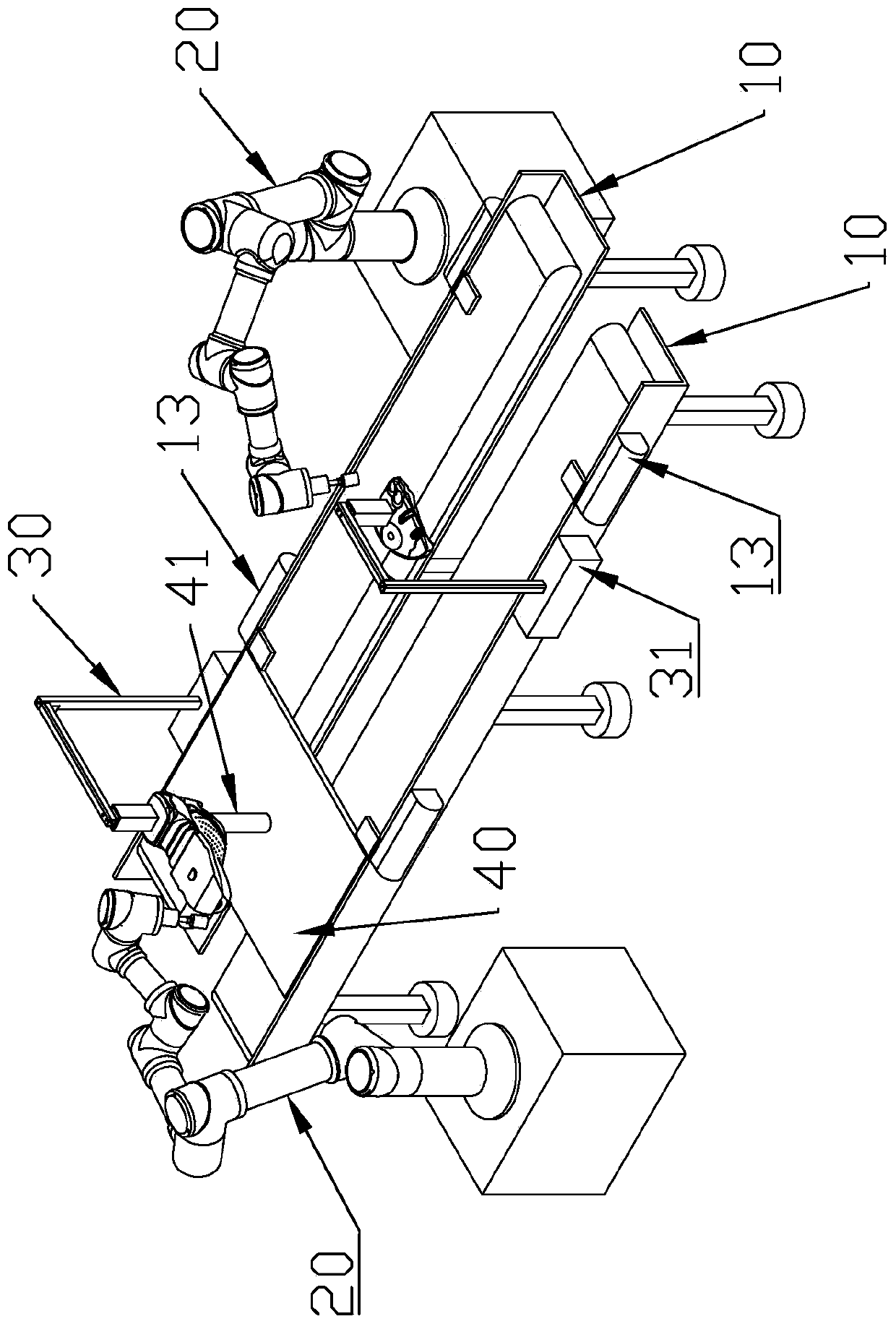

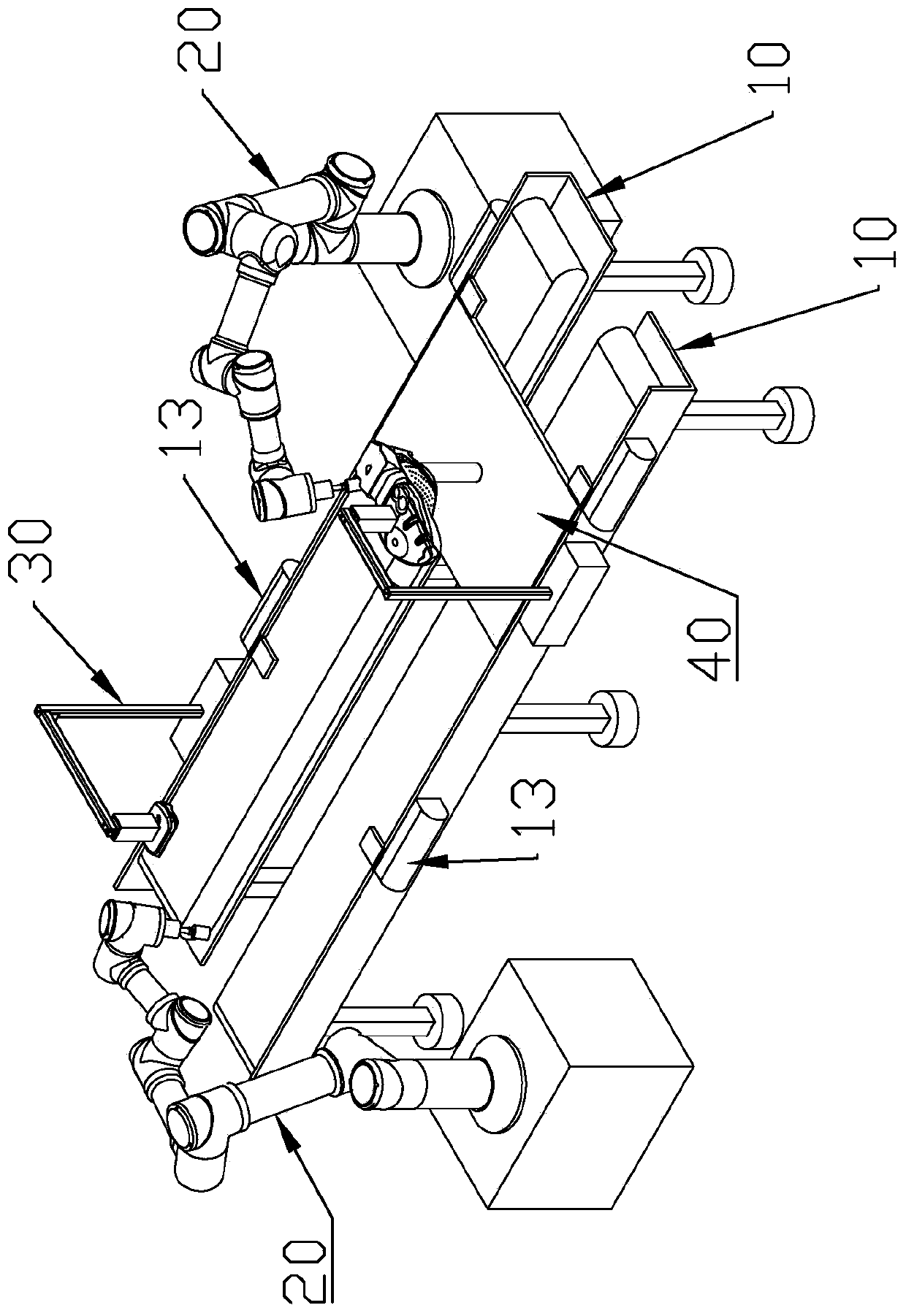

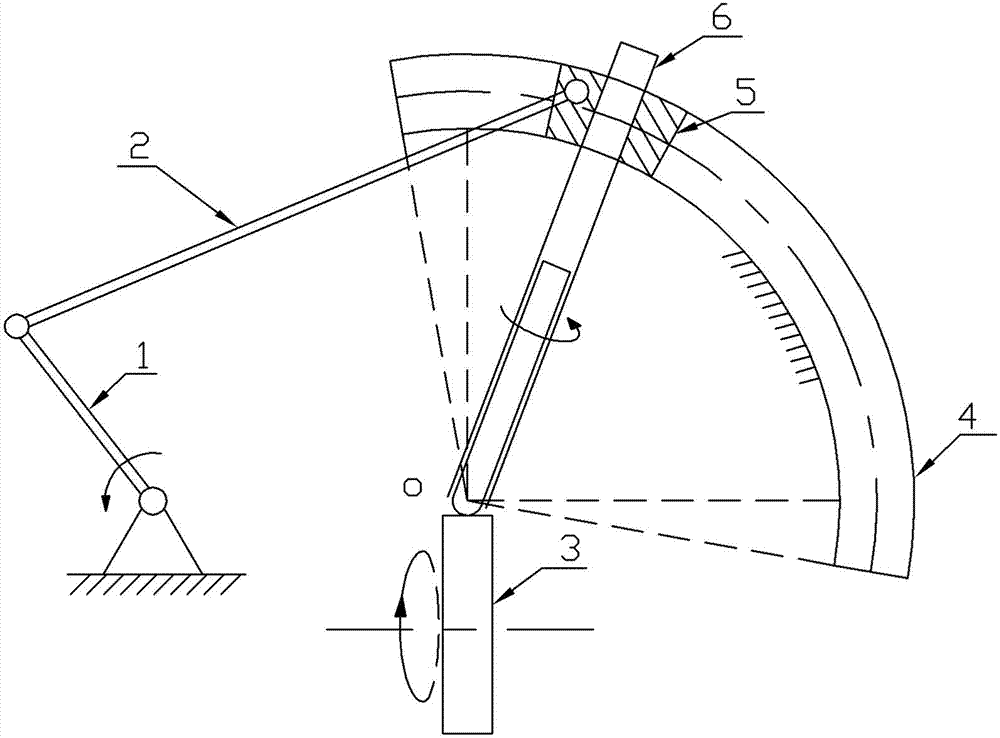

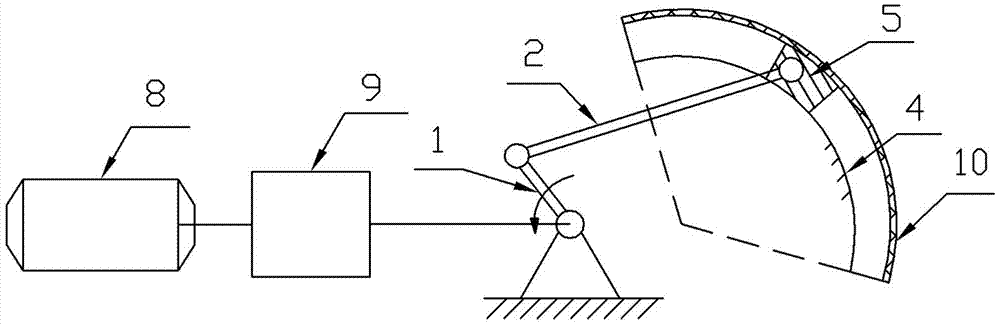

Method for grinding spherical surface of workpiece

InactiveCN102672576AReduce grinding errorReduce processing costsSpherical surface grinding machinesGrinding work supportsEngineeringGrinding wheel

The invention discloses a method for grinding the spherical surface of a workpiece. According to the method, the workpiece is coaxially and fixedly arranged at the clamping end of a clamping rotating shaft, so that the spherical center of the spherical surface to be machined on the workpiece is coincided with the revolving center of a revolving mechanism; during grinding, the clamping rotating shaft is driven by the revolving mechanism to do centering swing around the revolving center of the revolving mechanism, and the clamping rotating shaft is driven by a rotating shaft driving mechanism to drive the workpiece to rotate around the revolving central axis of the clamping rotating shaft; and a grinding wheel rotates around the revolving central axis of the grinding wheel, and a grinding working surface of the grinding wheel contacts the outer peripheral surface of the spherical surface to be machined on the workpiece to grind the workpiece. By the method, grinding errors are reduced effectively, and grinding accuracy is improved. In addition, the method for grinding the spherical surface is safe, reliable, simple, convenient, high in grinding efficiency and low in machining cost, and has high application value.

Owner:HENAN UNIV OF SCI & TECH

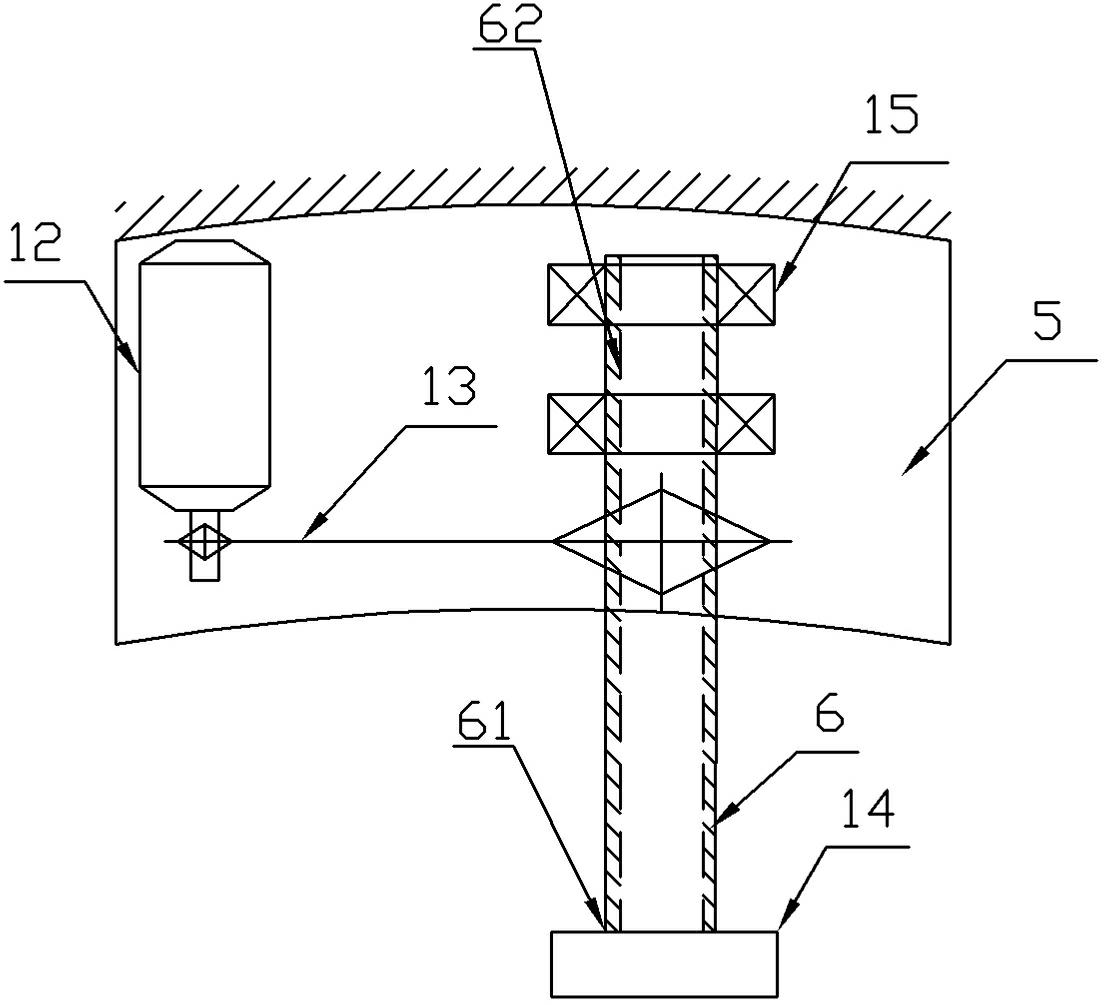

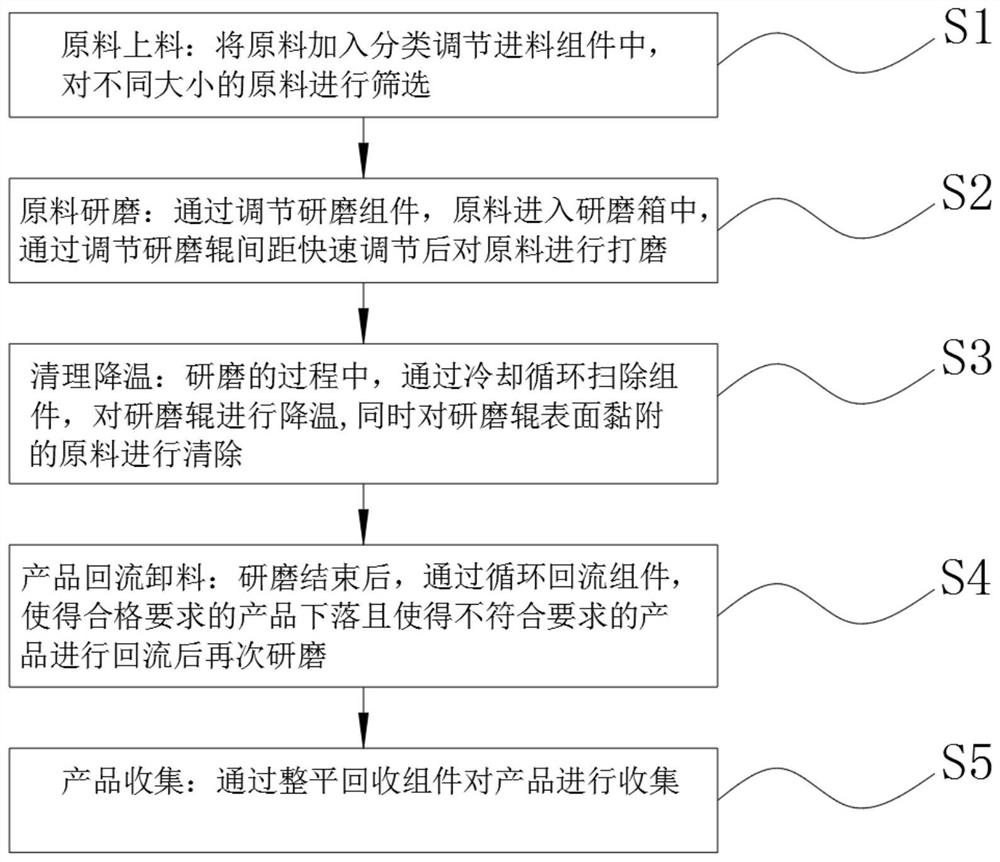

Preparation method for heat-conduction insulation silicone grease

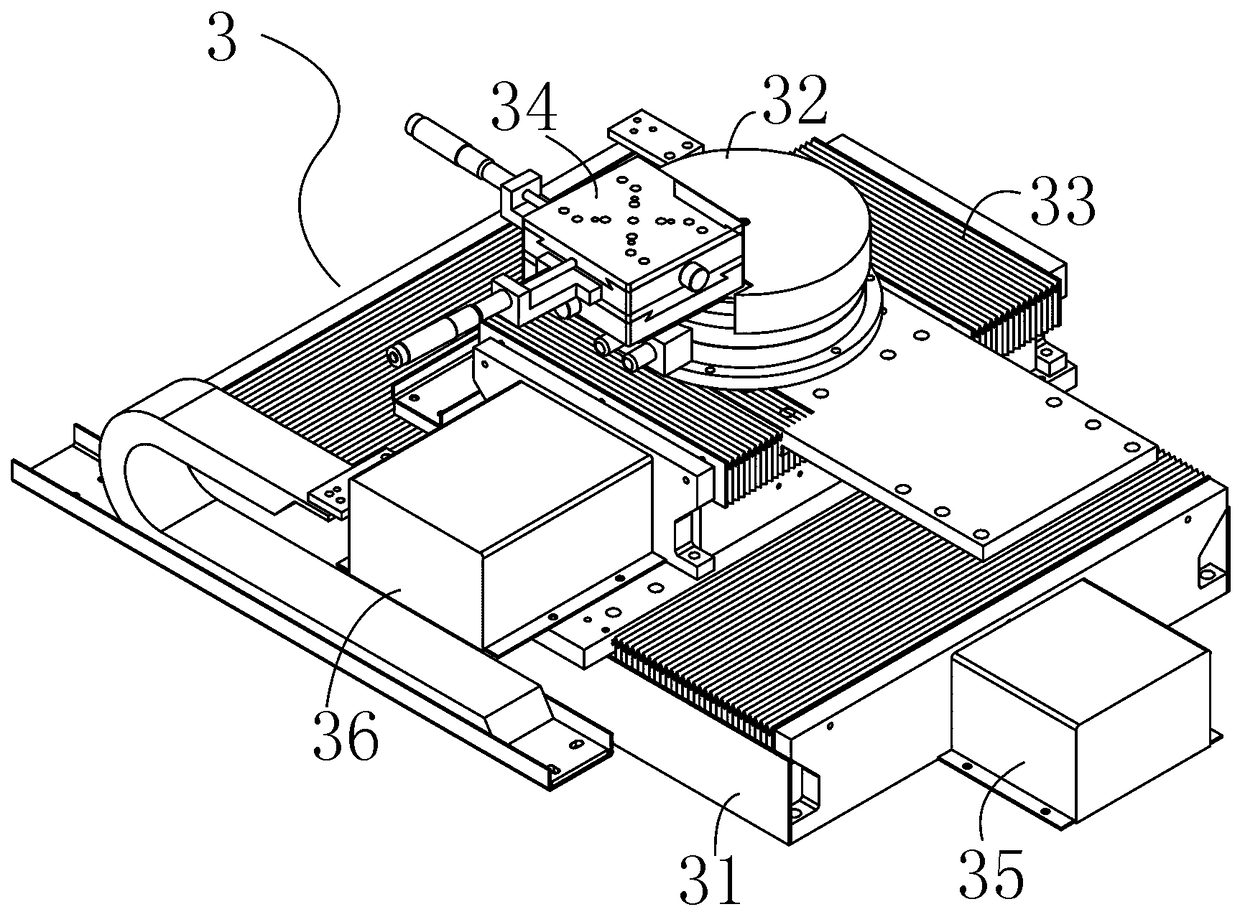

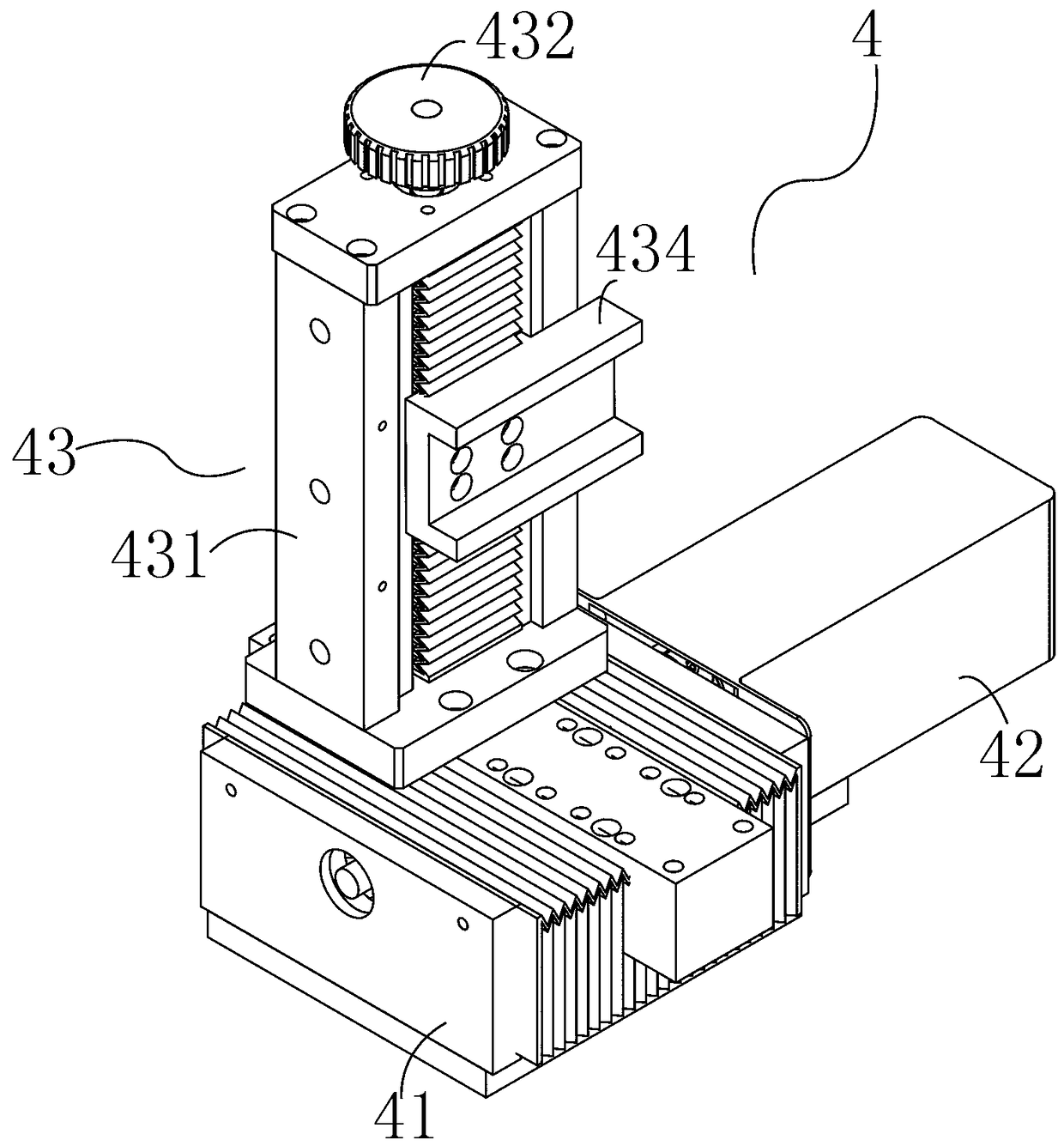

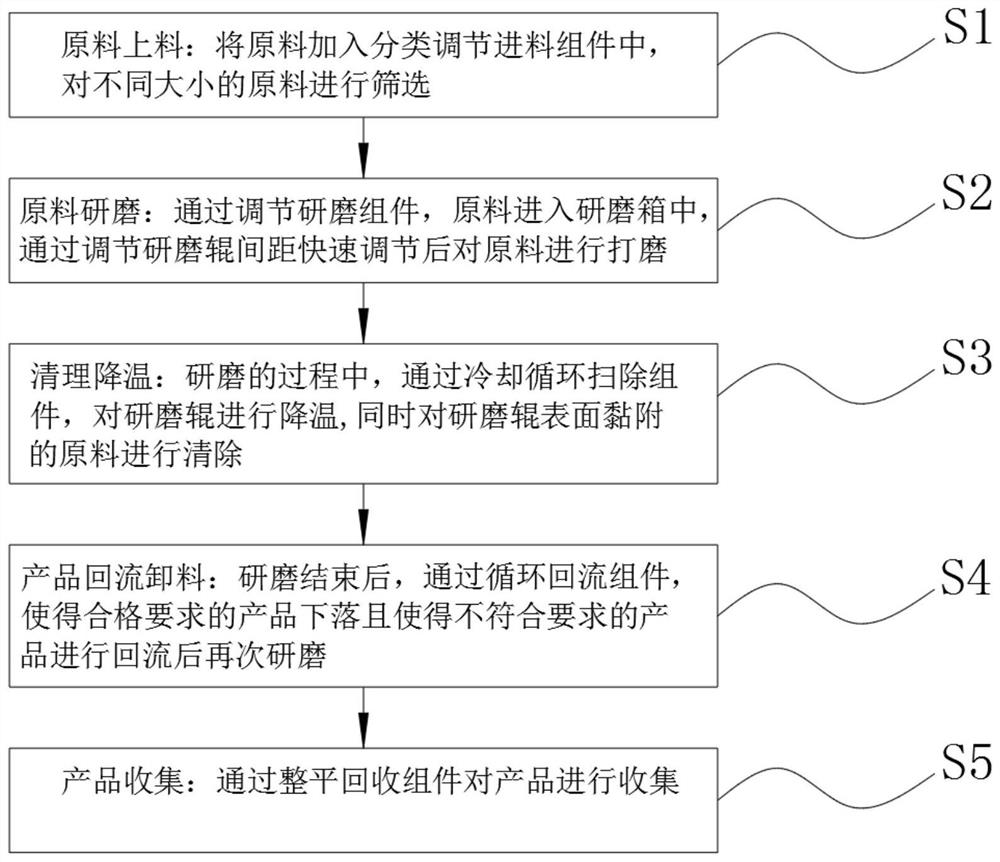

ActiveCN111841719AScientific and reasonable structureSafe to useGrain treatmentsThermal insulationGrinding

The invention discloses a preparation method for heat-conduction insulation silicone grease. The preparation method comprises a grinding box, wherein an installation rod is installed between the innerwalls of the grinding box through bolts; two ends of the installation rod are independently provided with a T-shaped groove; a T-shaped block is independently in sliding connection in each T-shaped groove; a shaking plate is in sliding connection in a shaking groove; the middle of the outer side of a rotary shaft is fixedly sheathed with a convex rod; two ends of the top surface of a filtering net are independently welded with a convex block; one end of the grinding box is provided with a fan; and positions, which are positioned on the bottom end positions of two bearing plates, of one end ofthe fan are independently connected with an air blowing pipe. Compared with the prior art, the preparation method is characterized in that a grinded product carries out inclined circular-arc movement, so that the product is even in dispersion to achieve a purpose of even blanking. A bottom end blocking problem of the grinding box enables raw materials which are not completely grinded to form circular arc shaped reflux, through the circular arc shaped reflux, the raw materials which are not completely grinded can enter between two grinding rollers along a raw material falling tangent direction, grinding quality and efficiency can be improved, and the problem of incomplete grinding is avoided.

Owner:苏州晶之电科技有限公司

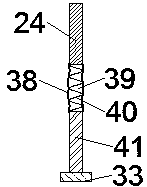

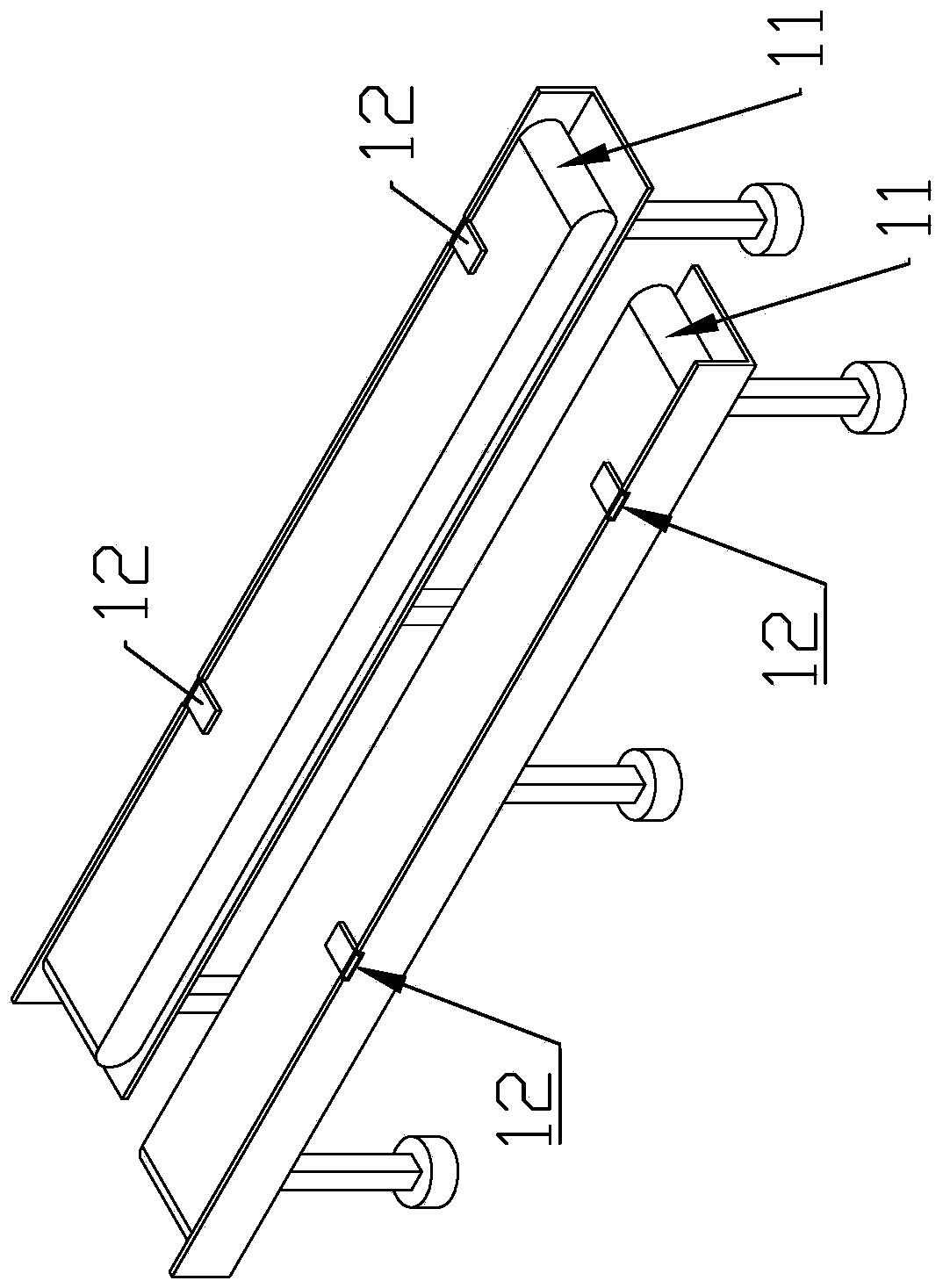

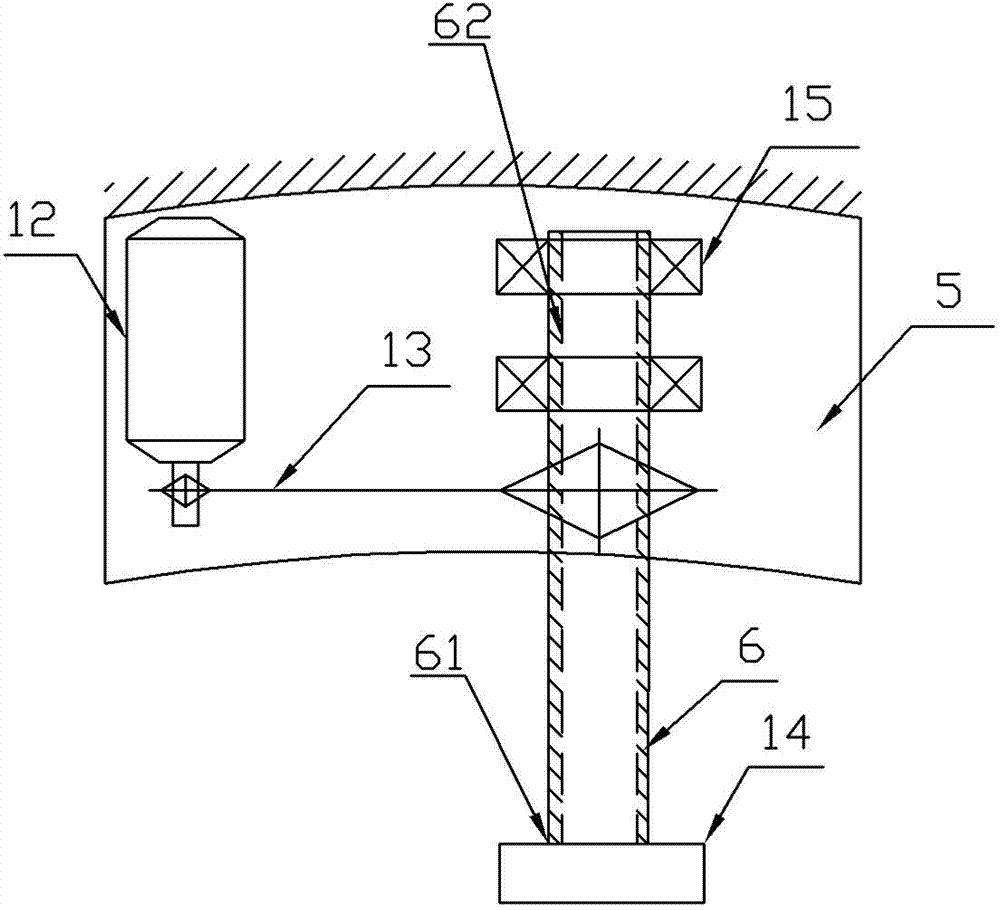

Work-piece contouring device

InactiveCN102672575AReduce grinding errorImprove grinding accuracySpherical surface grinding machinesEngineeringMechanical engineering

The invention discloses a work-piece contouring device, which comprises a grinding wheel and a clamping component, wherein the clamping component comprises a clamping rotating shaft, one end of the clamping rotating shaft is a clamping end, the clamping rotating shaft is driven to revolve on a self revolving central axis by a rotating shaft driving mechanism, the contouring device further comprises a revolving mechanism, the revolving mechanism drives the clamping rotating shaft to carry out centering swing around a revolving centre of the revolving mechanism, the grinding wheel is located near the revolving centre of the revolving mechanism, and the self revolving central axis of the grinding wheel is located in a swing plane, which is formed when the self revolving central axis of the clamping rotating shaft carries out centering swing on the clamping rotating shaft. When grinding, the clamping rotating shaft is driven to carry out centering swing around the revolving centre of the revolving mechanism, meanwhile, the rotating shaft driving mechanism drives the clamping rotating shaft to drive the work-piece to rotate around the self revolving central axis of the clamping rotating shaft, and a grinding working surface of the grinding wheel is in contact with the outer circumferential surface of a spherical surface to be processed on the work-piece to grinding the work-piece, so that a camber line on the outer circumferential surface of the spherical surface to be processed on the work-piece is obtained.

Owner:HENAN UNIV OF SCI & TECH

Industrial equipment grinding machine

InactiveCN105856048AQuality assuranceControl depthGrinding carriagesPolishing machinesIndustrial equipmentArchitectural engineering

The invention discloses an industrial equipment grinding machine which comprises a base. A placement platform and two mutually symmetrical support rods are respectively fixedly connected to the top of the base, one sides of the support rods, close to each other, are respectively provided with a slide, the inner bottom wall of the slide is fixedly connected with a spring, the other end of the spring is fixedly connected with a retaining plate, grooves are formed in two sides of the slide and are buckled with the retaining plates, dials are arranged on two sides of the slide, one side of each dial is fixedly connected with one side of each support rod, a cantilever plate is fixedly connected to the top of each support rod, two telescopic rods which are mutually symmetrical are fixedly connected to the bottom of the cantilever plate, and the other ends of the telescopic rods are respectively fixedly connected with a loose plate. By the arrangement, grinding depth can be effectively controlled, grinding accuracy is high, grinding error is low, and quality in grinding products is effectively guaranteed; the industrial equipment grinding machine is simple in operation, practical and convenient, and grinding efficiency is effectively improved.

Owner:李培培

Intelligent metal plate polishing device for automobile production

InactiveCN113352186AEasy to holdAvoid damageGrinding drivesGrinding feed controlInfrared thermometryPolishing

The invention relates to the technical field of metal plate polishing devices, and discloses an intelligent metal plate polishing device for automobile production. Through arrangement of a limiting spring and the like, to-be-polished workpieces of different sizes and different shapes are conveniently clamped, meanwhile, through arrangement of a pressure sensor and the like, intelligent clamping is achieved, and through arrangement of a scanning imager and the like, Intelligent polishing is achieved, and polishing errors are reduced; through the arrangement of an infrared thermometer and the like, the temperature of the polishing position is conveniently monitored in real time, the situation that the local temperature of a workpiece is too high, deformation is caused, and the polishing effect is affected is avoided; and on the other hand, intelligent polishing is achieved, and through the arrangement of a driving annunciator, a driving wire and the like, a central controller can indirectly control multiple electric sliding blocks to move conveniently, a polishing mechanism is indirectly driven to move at multiple positions through the arrangement of the multiple electric sliding blocks and a sliding rail, and therefore multi-direction and multi-angle polishing can be conveniently achieved for workpieces of different shapes and sizes, the purpose of self-adaptive clamping is achieved, and intelligent polishing is achieved.

Owner:DESIGN INST NO 9 MINISTRY OF MECHINE BUILDING

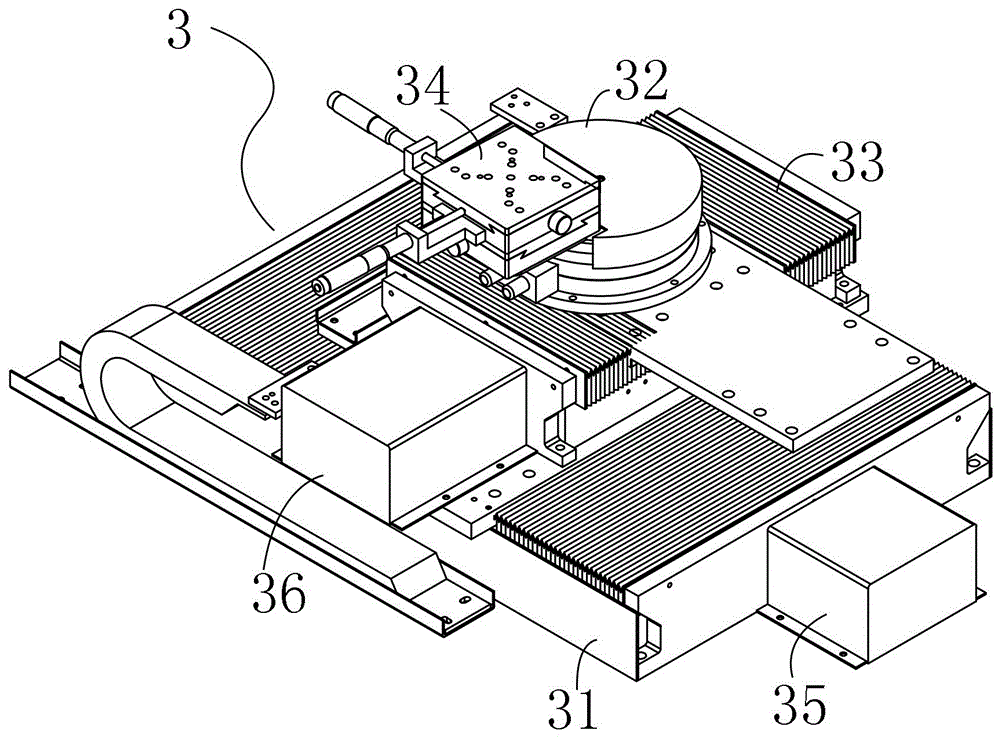

Numerical control drill double relief angle blade milling machine

ActiveCN101774137BReduce grinding errorCorrect shape exactlyTwist drillsNumerical controlMotor drive

The invention relates to a numerical control machine device, in particular to a numerical control machine device carrying out grinding processing on a drill. The invention aims to provide a numerical control drill double relief angle blade milling machine. The device can carry out grinding processing on relief angles of the drills with different specifications and has high processing precision, high efficiency, good consistency and good safety. The numerical control drill double relief angle blade milling machine is provided with a stander, an electrical cabinet, a hydraulic device, an operation panel and a lubricating device. The stander is provided with a grinding wheel unit. The grinding wheel unit comprises a grinding wheel rack fixed on the stander, a grinding wheel in adjustable connection with the grinding wheel rack and a driving motor driving the grinding wheel to rotate. The grinding wheel rack is provided with a grinding wheel feeding device. The grinding wheel feeding device is provided with a grinding wheel feeding cylinder driving the grinding wheel to move. The front side of the grinding wheel rack on the stander is provided with an automatic loading device. The automatic loading device comprises a hopper storing processed components, a hopper cylinder driving the hopper, a trough for operating the components, a feeding rod and a feeding cylinder driving the feeding rod. A drill clamping device is arranged on the right side of the automatic loading device on the stander and comprises a chuck, a servo motor driving the chuck to rotate, a clamping cylinder anda brake cylinder. The lower part of the drill clamping device is provided with a chuck feeding device. The chuck feeding device comprises a guide rail which supports the drill clamping device and provides moving guide for the drill clamping device and a chuck feeding cylinder driving the drill clamping device to move.

Owner:NANJING CHENGUANG GRP

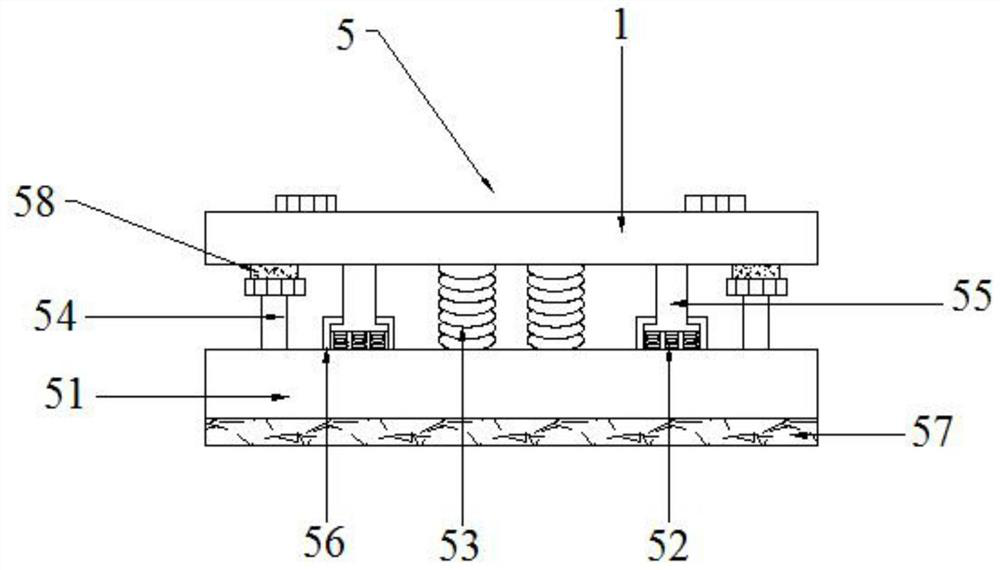

Polishing device for mechanical part machining

InactiveCN111975548AEven sandingEasy to operateGrinding drivesGrinding machinesPolishingElectric machinery

The invention relates to a polishing device for mechanical part machining. The polishing device for mechanical part machining comprises a base plate, U-shaped fixed plates, a servo motor, a fixing assembly and a shock absorbing assembly. The U-shaped fixed plates are welded and fixed to two sides of the upper surface of the base plate, the output end of the servo motor is welded and fixed to rotating bases on the U-shaped fixed plates, a polishing head is connected and fixed to the output end of the polishing motor in a clamping manner, the fixing assembly is arranged at the bottom end of thepolishing head on the upper surface of the base plate, and an operating assembly is arranged on the side of the fixing assembly on the base plate. The polishing device has the beneficial effects thatthe servo motor drives a movable block on a threaded rod to move on a fixed bar to drive the polishing head to adjust, so that the polishing device is smooth to polish and convenient to operate; a platy mechanical part is stably and safely by means of the fixing block and the U-shaped movable block under a second electrical push rod, so that the polishing device is safe to operate; and a first shock absorbing spring buffers vibration on the shock absorbing base, so that noises are reduced and the environment is protected.

Owner:卫浩

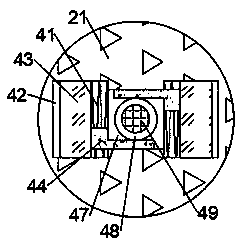

Hook face precision abrasive belt grinding head

InactiveCN109590865AIncrease in sizeExtended service lifeBelt grinding machinesDrive wheelEngineering

The invention discloses a hook face precision abrasive belt grinding head. The hook face precision abrasive belt grinding head comprises a mounting shell, a spindle, a supporting rod, a driving wheel,a contact wheel, a transition wheel set and an abrasive belt; the spindle is arranged in the middle of the mounting shell, the driving wheel is arranged on the end of the spindle, the supporting is arranged at one end of the mounting shell, the contact wheel is arranged on the supporting rod, the transition wheel set is arranged on the other end of the mounting shell, the abrasive belt is sequentially wound on the driving wheel, the transition wheel set and the contact wheel, and the driving wheel and the contact wheel are linked; according to the hook face precision abrasive belt grinding head, the grinding part is arranged to the abrasive belt, through contact of the contact wheel and the welding line, the welding line can be subjected to contact grinding, and compared with the prior art, shaking in the manual grinding process is avoided, and the grinding process is more stable. In addition, according to the abrasive belt, due to the fact that the width of the grinding head is small, and the path is long, the wound abrasive belt is small in size and long, the service life of the abrasive belt is long, and the grinding cost is reduced.

Owner:CHONGQING UNIV +1

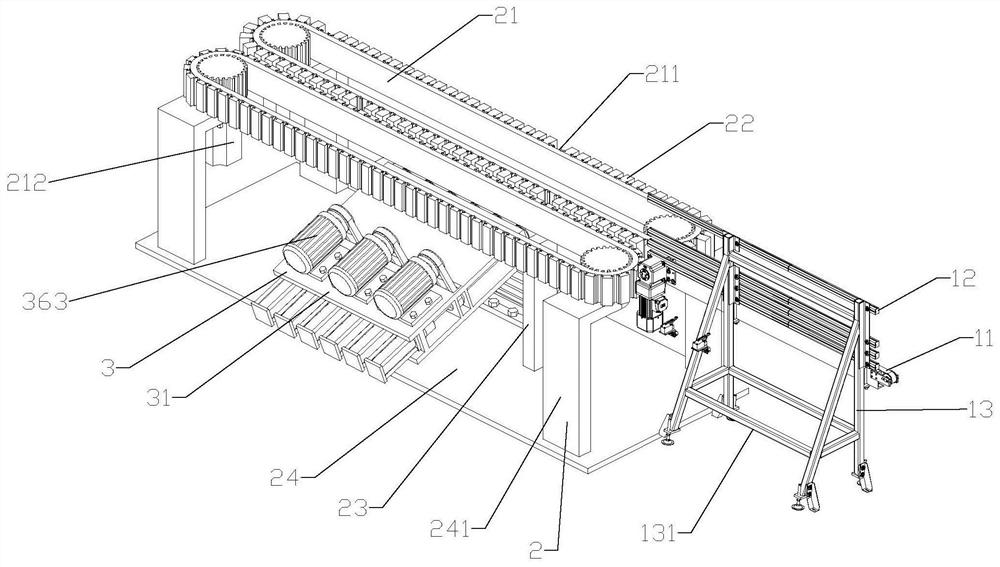

Quartz stone chamfering machine

InactiveCN112318268AEasy to placeQuick gripEdge grinding machinesConveyorsStructural engineeringQuartz

The invention discloses a quartz stone chamfering machine. The quartz stone chamfering machine comprises a feeding frame and a conveying frame, a synchronous belt is horizontally arranged on the feeding frame, and a plurality of rows of righting rods are horizontally arranged on one side above the synchronous belt. The conveying frame is arranged on the front side of the feeding frame, two conveying belts are symmetrically arranged on the conveying frame, and a plurality of elastic clamping blocks are detachably arranged on one conveying belt at equal intervals. A grinding device is arranged below the conveying belts and comprises a box body, grinding shafts, polishing pieces and grinding shaft driving air cylinders, the multiple grinding shafts are rotatably arranged in the box body sideby side, the grinding shafts are rotatably and telescopically arranged on the box body, one end portion of each grinding shaft penetrates out of the box body, and the polishing pieces are fixed to theend portions of the grinding shafts; the other end of each grinding shaft is sleeved with a sleeve which is fixedly connected with a piston rod of the corresponding grinding shaft driving cylinder; and a grinding shaft driving mechanism capable of driving each grinding shaft to rotate is arranged on the box body. The quartz stone chamfering machine has the characteristics of being high in efficiency, capable of achieving automatic clamping and capable of grinding a quarter of an arc.

Owner:上海赫峰企业发展集团有限公司

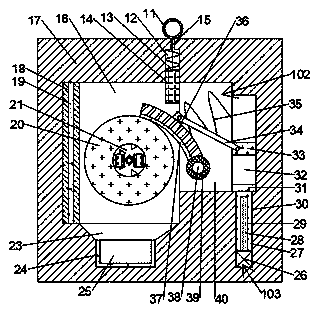

Calibration grinding tool capable of avoiding special-shaped errors by grinding wheel

InactiveCN111203774AReduce grinding errorSolve the deformationEdge grinding machinesGrinding wheel securing apparatusElectric machineryEngineering

The invention discloses a calibration grinding tool capable of avoiding special-shaped errors by a grinding wheel. The calibration grinding tool comprises a shell, a grinding cavity with a forward opening is formed in the shell, a power cavity is formed in the rear side of the grinding cavity in a communicating mode, a first motor is fixedly arranged on the rear wall of the power cavity, a power column is arranged on the front side surface of the first motor in a power connection mode, the forward extending part of the power column extends into the grinding cavity, the grinding wheel can be loaded on the periphery of the grinding cavity, a limiting ring is fixedly arranged on the periphery of the grinding cavity, and the limiting ring can limit slipping of the grinding wheel. According tothe calibration grinding tool capable of avoiding the special-shaped errors by the grinding wheel, an arc-shaped grinding plate can abut against the grinding wheel in a common elastic abutting mode and a mechanical pressure abutting mode, thus the outer side surface of the grinding wheel is ground in the rotating process, the standard size is achieved, the grinding errors by the grinding wheel inthe using process are greatly reduced, and the quality of a product ground by the grinding wheel is improved.

Owner:YONGKANG XUEFANG AUTOMATION EQUITMENT CO LTD

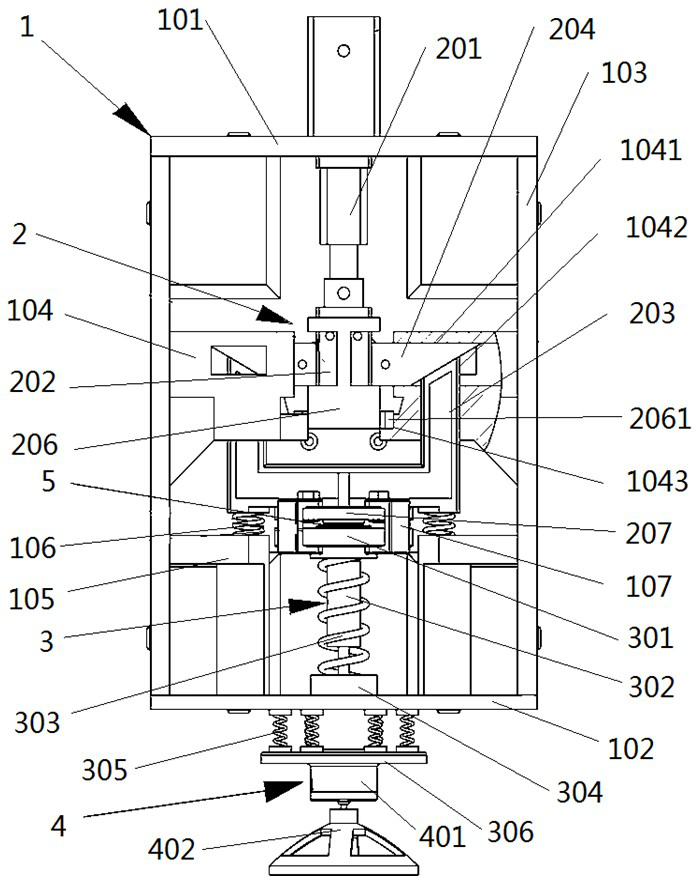

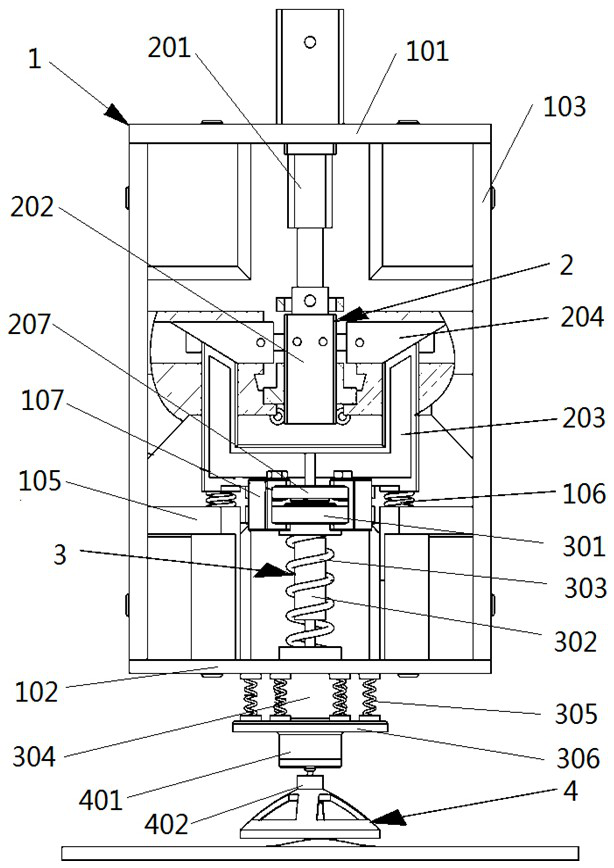

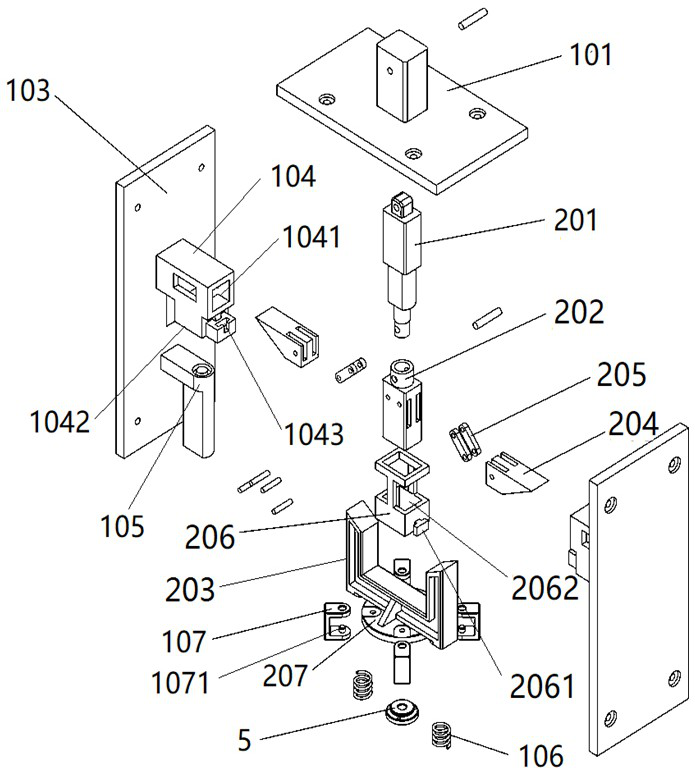

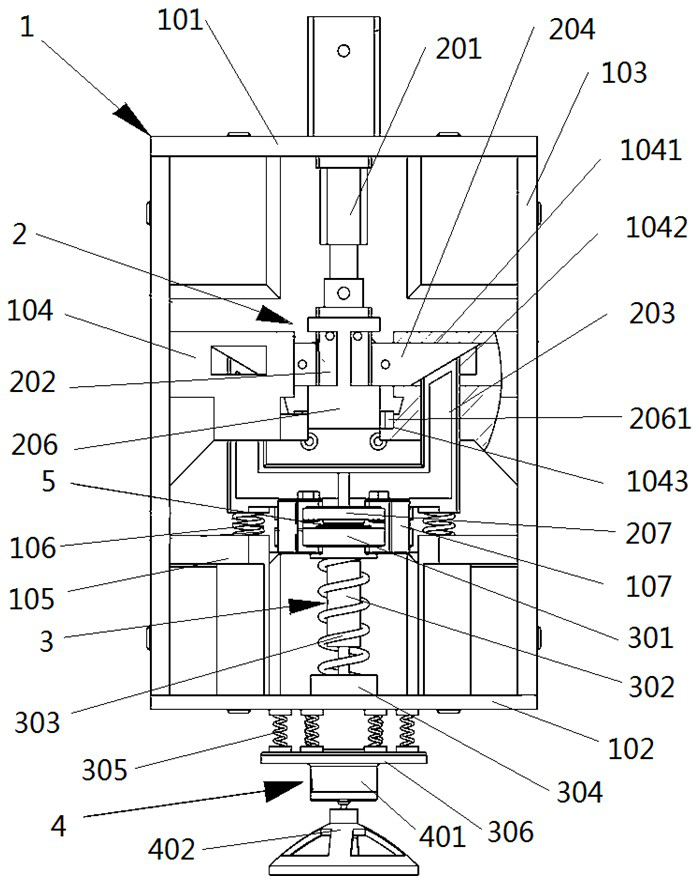

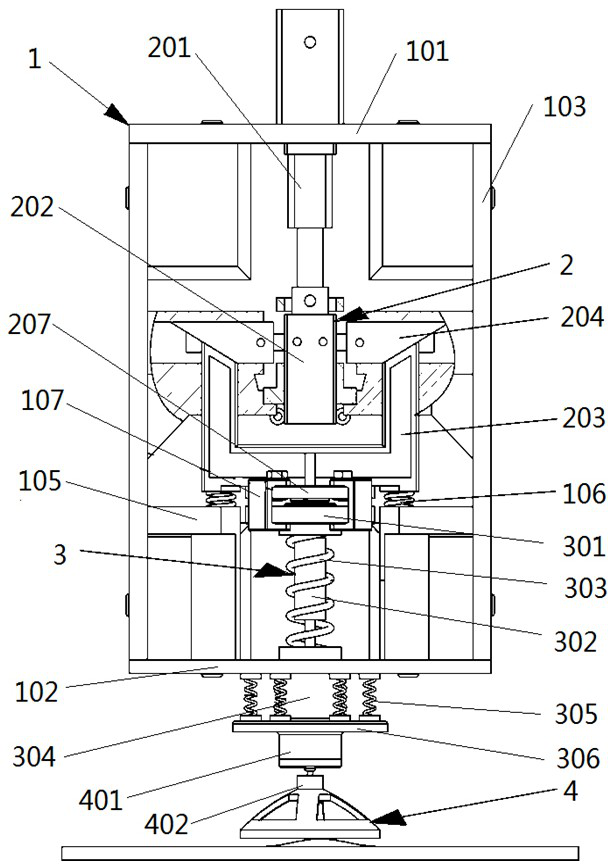

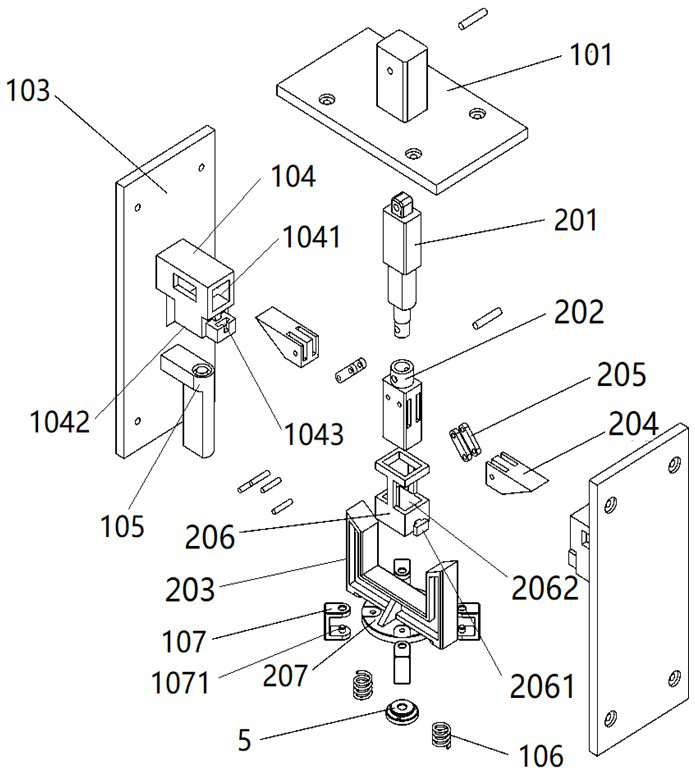

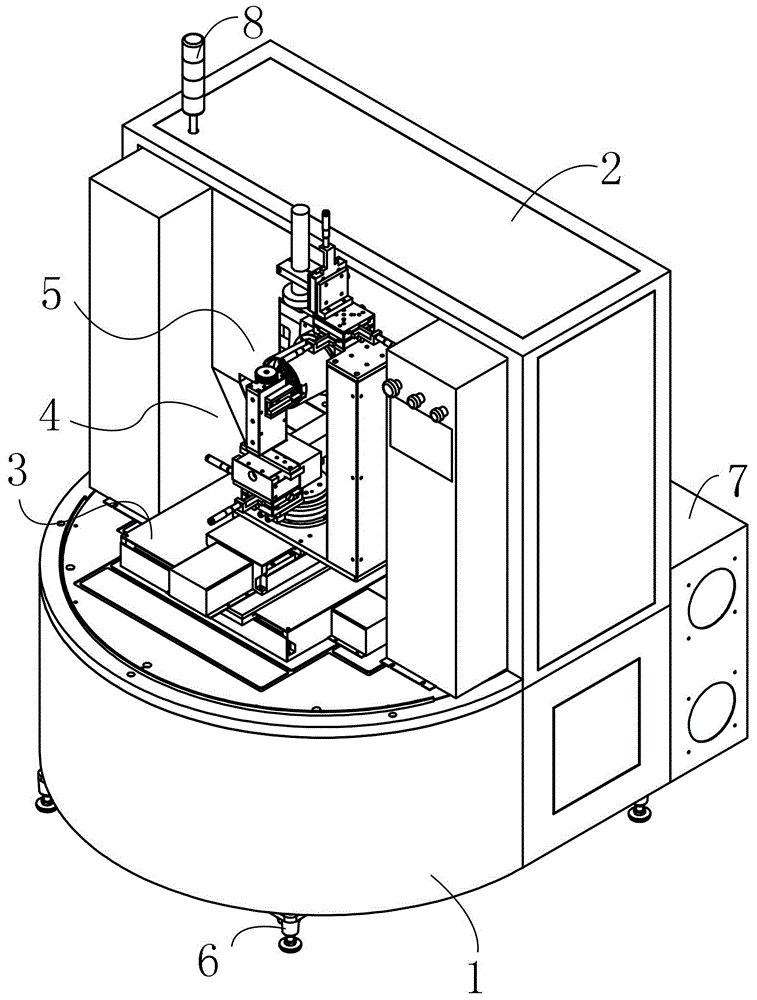

Variable-stiffness flexible grinding and polishing actuator

ActiveCN113001398AConstant stiffnessEasy to GrindGrinding feed controlAutomatic grinding controlSolid woodPolishing

The invention discloses a variable-stiffness flexible grinding and polishing actuator, and belongs to the technical field of solid wood panel machining. The variable-stiffness flexible grinding and polishing actuator comprises a box body, an active flexible mechanism, a passive flexible mechanism and a grinding and polishing head mechanism arranged outside the box body; the active flexible mechanism and the passive flexible mechanism are arranged in the box body from top to bottom; a pressure sensor is arranged between the active flexible mechanism and the passive flexible mechanism, and the grinding and polishing head mechanism is connected with the passive flexible mechanism. The problem that active and passive flexible separation of a common grinding and polishing machine has many defects can be solved.

Owner:HEFEI UNIV OF TECH

Size grading measuring tool

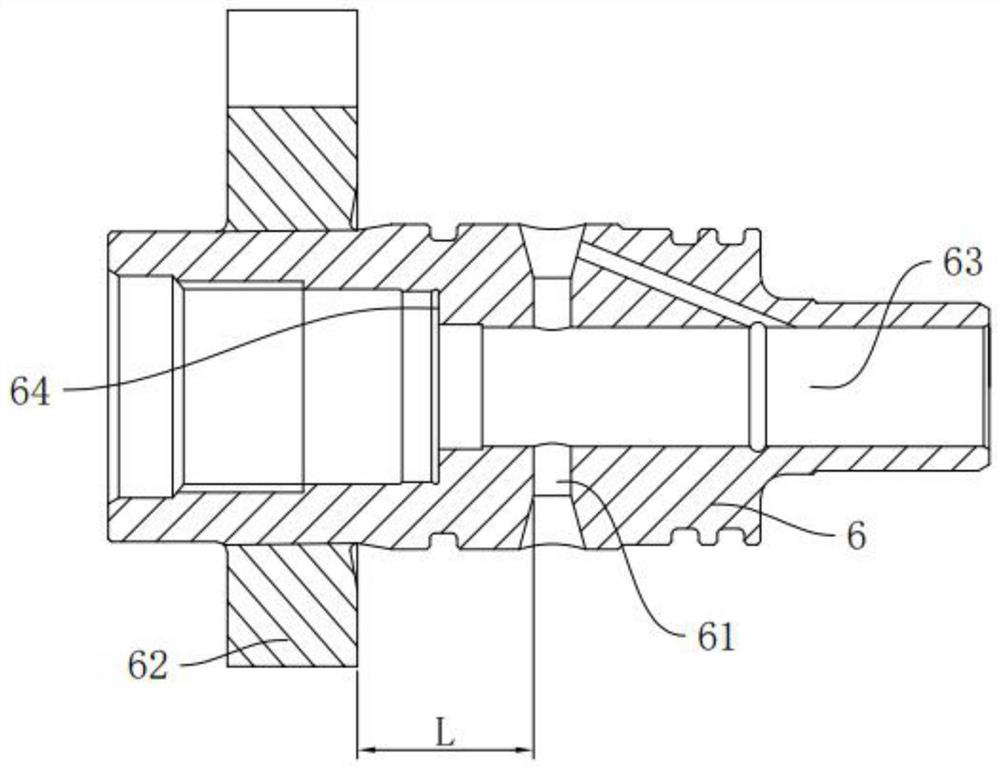

InactiveCN113649857AReduce grinding errorGuarantee product qualityMechanical clearance measurementsMeasurement/indication equipmentsEngineeringMachining

The invention relates to a size grading measuring tool. The size grading measuring tool comprises a support, a locating piece and a dial indicator, wherein the support is provided with a sliding part, the sliding part is used for bearing a to-be-measured body and allowing the body to slide relative to the support, and the sliding direction of the body is parallel to the axis of the body; the locating piece is in sliding fit with the support, the sliding direction of the locating piece is perpendicular to the sliding direction of the body, and the locating piece is in insertion fit with an oil hole; and the axis of a measuring rod of the dial indicator is parallel to the sliding direction of the body, and when the to-be-measured body is placed on the sliding part, a measuring head of the dial indicator abuts against the mounting face so as to measure the distance error between the edge of the oil hole and the mounting face when the locating piece is inserted into the oil hole. The grinding error of a first distance can be reduced, and the production quality of an integral flange plunger sleeve is guaranteed. In addition, the bodies can be graded according to different feed rates of the bodies, and batch machining is facilitated.

Owner:无锡威孚马山油泵油嘴有限公司

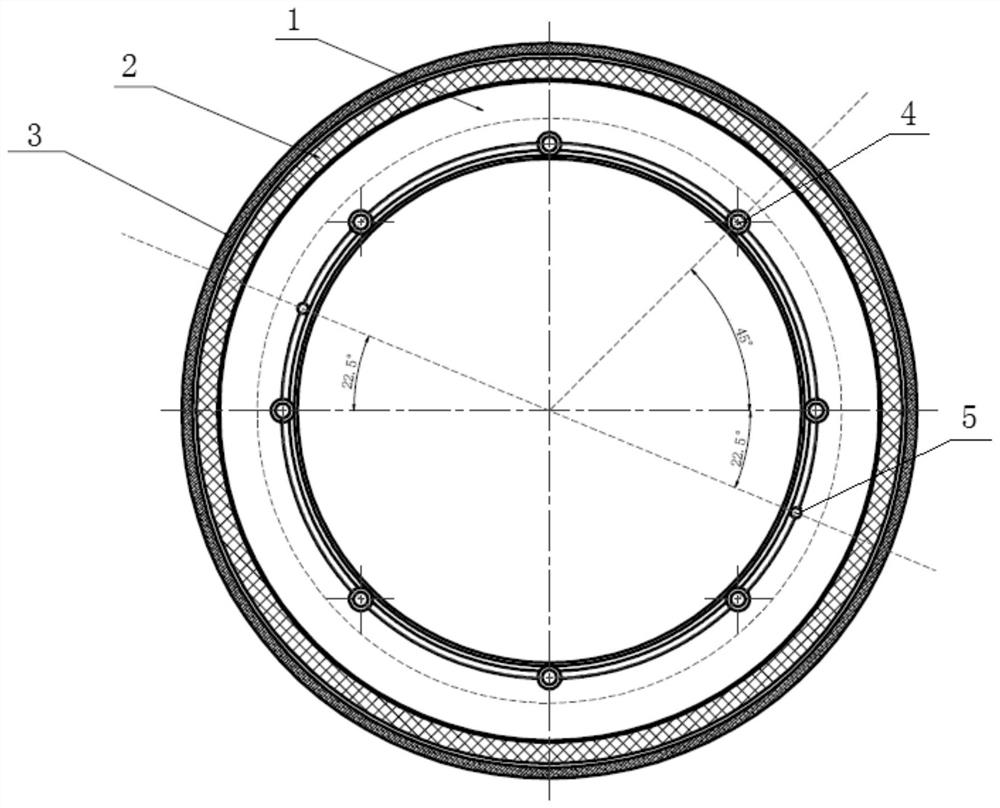

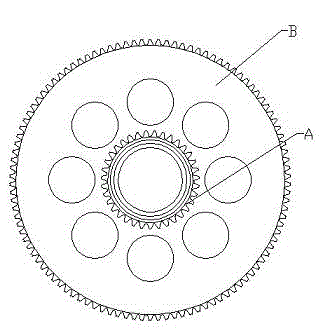

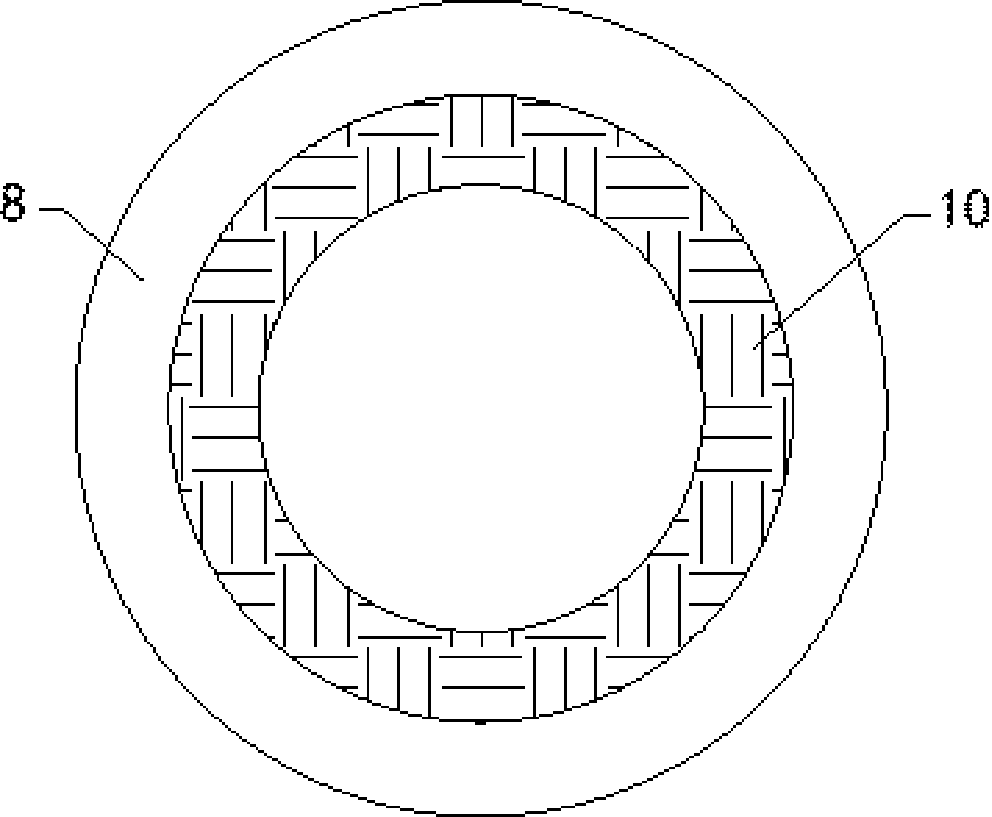

A peripheral grinding wheel for rough and fine grinding of pcbn blades

ActiveCN110977796BQuality assuranceImprove grinding efficiencyBonded abrasive wheelsGrinding wheelKnife blades

The invention discloses a peripheral grinding wheel for rough and fine grinding of PCBN blades, comprising a grinding wheel body and an abrasive layer located on the outer ring surface of the grinding wheel body, the abrasive layer is bonded to the outer ring surface of the grinding wheel body through a ceramic bond, The abrasive layer is a fine-grain diamond abrasive layer or a coarse-grain diamond abrasive layer. The abrasive layer includes a first abrasive layer and a second abrasive layer. The second abrasive layer covers part of the outer ring surface of the first abrasive layer. The first abrasive layer is coarse grain The diamond abrasive layer, the second abrasive layer is a fine-grained diamond abrasive layer, and there are 8 installation through holes evenly distributed around the axis of the grinding wheel body at the inner ring of the grinding wheel body. The structure design of the grinding wheel of the invention is reasonable. After the rough machining is completed, there is no need to replace the machine tool and the grinding wheel, which can reduce the configuration of the machine tool, reduce the grinding error caused by repeated clamping, improve the grinding efficiency, and ensure the grinding The cutting edge quality improves the installation accuracy.

Owner:上海新山田精密刀具有限公司

Polishing machine capable of conveniently polishing powder metallurgy mold cavity

InactiveCN110814955AReduce grinding errorImprove grinding and polishing effectGrinding carriagesGrinding machinesPolishingEngineering

The invention discloses a polishing machine capable of conveniently polishing a powder metallurgy mold cavity. The polishing machine includes a machine body and a first T-shaped slide bar, the first T-shaped slide bar penetrates through an inner wall of the machine body, the first T-shaped slide bar is slidingly connected to the machine body, the periphery of the first T-shaped slide bar is provided with a fixing mechanism which can fix the first T-shaped slide bar on the left and right sides of a mold, can achieve front and back rotation and adjustment by a certain angle and enables the machine body to be in the middle portion of the mold all the time, and the front and back faces of the machine body are provided with clamping mechanisms for stabilizing the machine body. By means of the polishing machine, the cavity of the mold in use can be polished at any time, the mechanical clamp manner reduces the polishing errors generated by manual operation, and the grinding and polishing effects are effectively improved; and through the elastic effect, a polishing head can always be attached to the inner wall of the cavity, and the grinding efficiency is improved.

Owner:SHENGZHOU YUEMING MOULD TECH CO LTD

Grinding die for pinion of duplicate gear

The invention discloses a grinding die for a pinion of a duplicate gear. The grinding die comprises an upper die base and a lower die base which are in sliding connection through a guide column, wherein a lower die for fixing the duplicate gear is arranged on the upper portion of the lower die base, the corresponding positions of the upper die base and the lower die base are connected with a tooth-shaped grinding device for grinding the pinion of the duplicate gear, and the tooth-shaped grinding device can move vertically relative to the lower die. By means of the technical scheme, the grinding accuracy is ensured, grinding errors are reduced, radial jumping caused by grinding of one gear is avoided simultaneously, and the positions of a rack wheel and the pinion are consistent. Production efficiency is improved, production cost is reduced, and the grinding die can be produced in volume mode. A rotary vector (RV) reducer is high in accuracy of rotating displacement, can ensure the accuracy of positioning of a grinding cutter and the gear and improves machining accuracy.

Owner:HUACHUANG ROBOT MFG

Rapid grinding device for building steel with fixed size

InactiveCN114559345AReduce grinding errorImprove work efficiencyGrinding carriagesGrinding drivesElectric machineryStructural engineering

The invention discloses a rapid grinding device for building steel with a fixed size, and relates to the field of building engineering. The rapid grinding device for the building fixed-size steel comprises a fixing frame, the top of the inner wall of a rotating sleeve is rotationally connected with a rotating disc, the lower surface of the rotating disc is rotationally connected with the upper surface of the fixing sleeve, a first rotating ferrule is rotationally connected with a first limiting rod, and the fixing sleeve is in rolling connection with a second rotating ferrule. And the second rotating ferrule is rotationally connected with the second limiting rod. According to the rapid grinding device for the building steel with the fixed size, by arranging a first connecting shaft, a rotating sleeve, a first rotating ferrule and a limiting block, the device does not need to be taken down to change the angle, the working efficiency is improved, a plurality of workpieces can be ground at the same time, and the grinding error of the workpieces of the same kind is reduced; the workpiece sequentially passes through the first grinding device and the second grinding device, the grinding speed is increased, and grinding of workpieces of the same size is facilitated.

Owner:李东阁

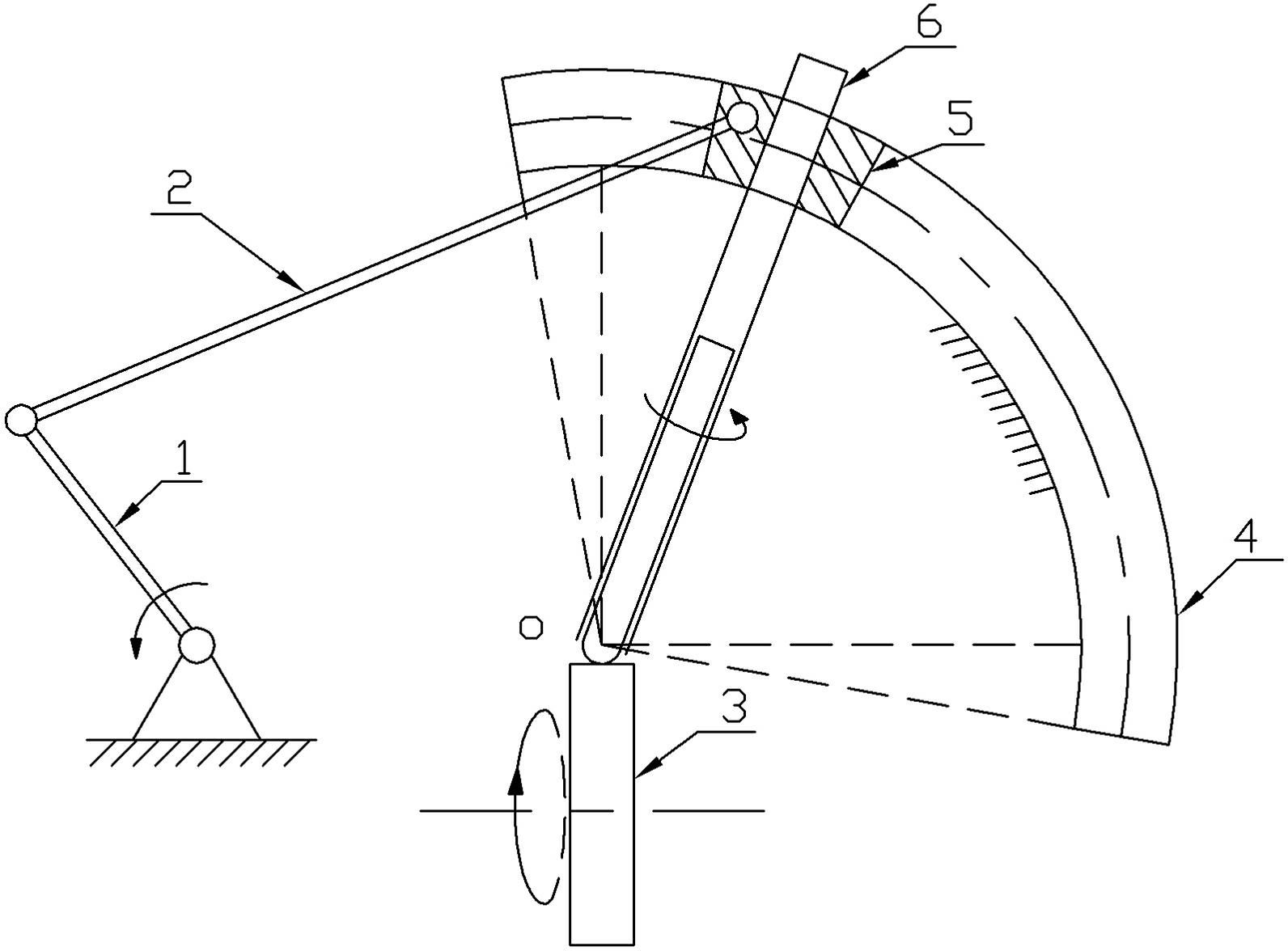

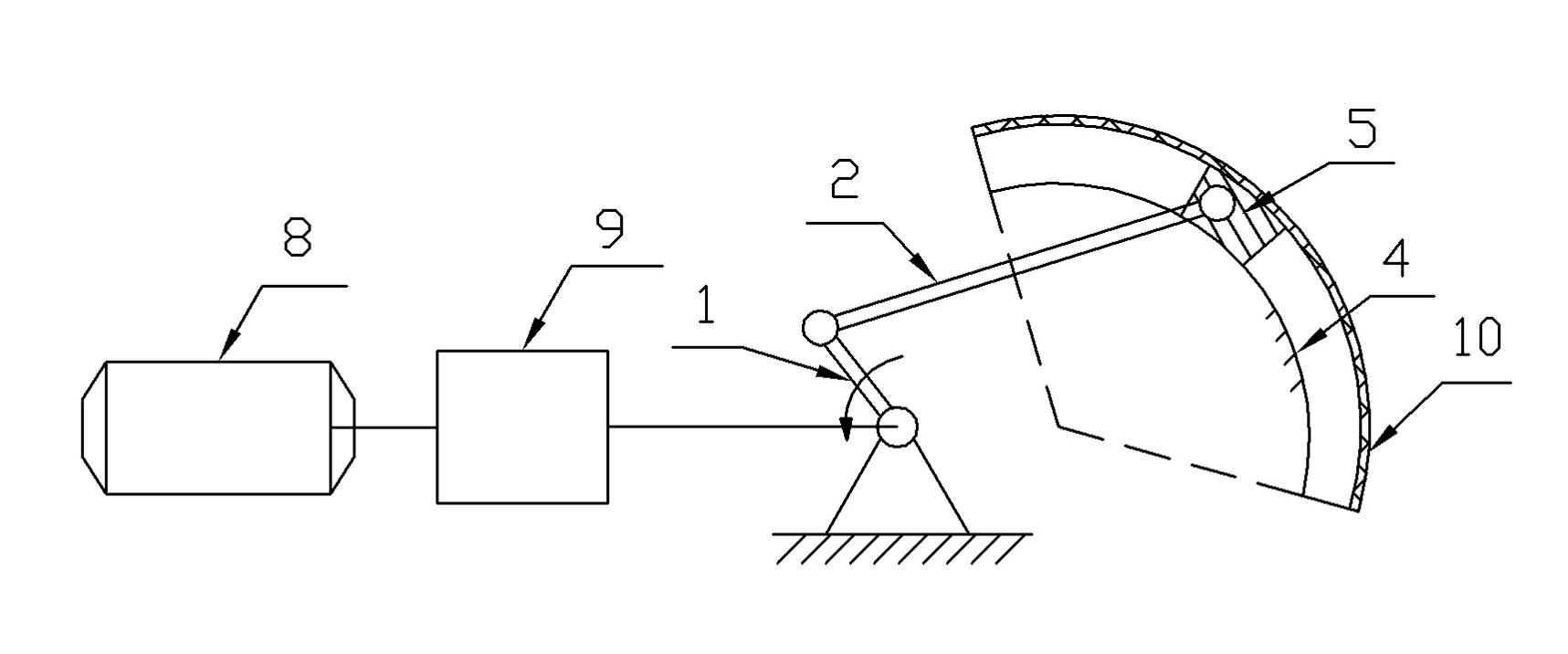

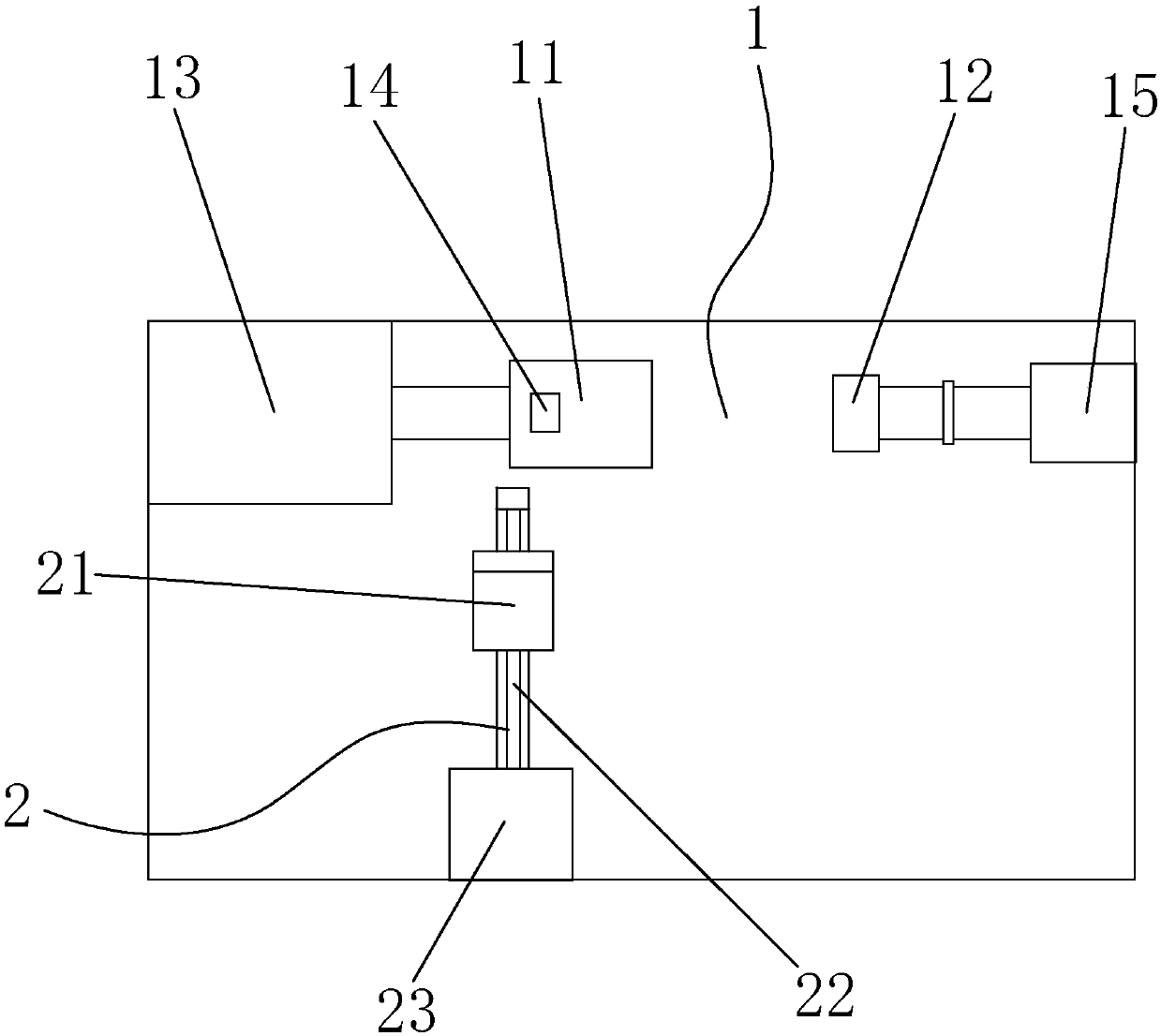

Grinding wheel spindle variable-angle automatic control system of fully-automatic digital control roll grinding machine

ActiveCN101829932BReduce grinding errorImprove grinding accuracyRevolution surface grinding machinesAutomatic grinding controlAutomatic controlRadial plane

The invention discloses a grinding wheel spindle variable-angle automatic control system of a fully-automatic digital control roll grinding machine. A fully-digital alternating current (AC) servo motor outputs power to a ball screw assembly; the ball screw assembly is in threaded connection with a nut sleeve; a guide bar is connected with the nut sleeve by a positioning sliding block; one end of an swing link is arranged on the nut sleeve; a counterweight block is fixedly connected with the swing link; a sleeve is fixedly sleeved on the outer side of a hydrodynamic-hydrostatic grinding head; the sleeve is axially slanted relative to the hydrodynamic-hydrostatic grinding head; the intersection point of the shaft axis of the sleeve and the central line of a main shaft of a hydrostatic eccentric bushing of the hydrodynamic-hydrostatic grinding head is positioned on the radial plane of the geometric centre of a grinding wheel of the hydrodynamic-hydrostatic grinding head; the outer side of the sleeve can be rotatably positioned on a grinding machine frame; the other end of the swing link is fixedly connected with the sleeve; and the principal axis of the hydrostatic eccentric bushing and the principal axis of the grinding wheel are driven by the sleeve to swing relative to the roller shaft axis around the geometric centre point of the grinding wheel, so the work surface of the grinding wheel is always tangent to the roller surface, the error of camber grinding is reduced, helix lines are prevented from generating on the roller surface, and the accuracy, the quality and the efficiency of the camber grinding are improved.

Owner:HIECISE PRECISION EQUIP (KUNSHAN) CO LTD

A kind of burr trimming machine for blockboard processing

ActiveCN113547409BAngle adjustableReduce grinding errorEdge grinding machinesGrinding work supportsPolishingMachine

The present invention is applicable to the technical field of wood board processing, and provides an edge trimming machine for blockboard processing, which includes a support base frame, an edge trimming guide assembly, and an edge trimming assembly, and the edge trimming assembly includes a fixed shell, a rotating shell, and a grinding Roller: through the trimming guide assembly and the setting of the trimming assembly, the purpose of guiding the trimming assembly along a certain path with the blockboard for grinding through the trimming guide assembly is realized, without manual control of the movement of the trimming machine, reducing the The grinding error in the trimming process and the setting of the three-stage combined trimming component make the angle of the grinding drum adjustable, and the trimming machine can be adjusted to adapt to the grinding of more blockboards with different corner specifications. Edge trimming is more convenient to use, and solves the problem in the prior art that multiple reciprocations are required to polish adjacent surfaces.

Owner:江苏德鲁尼智能家居有限公司

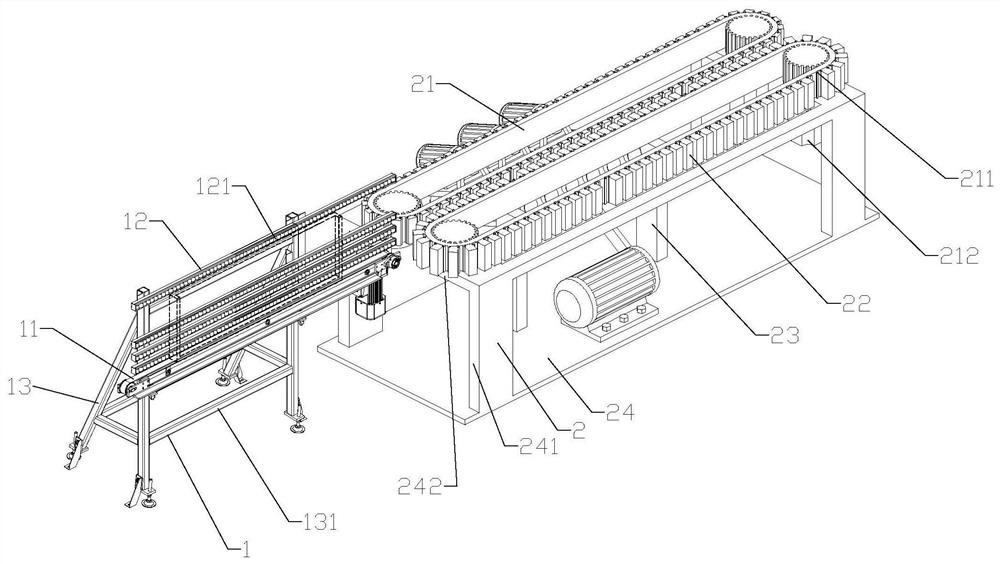

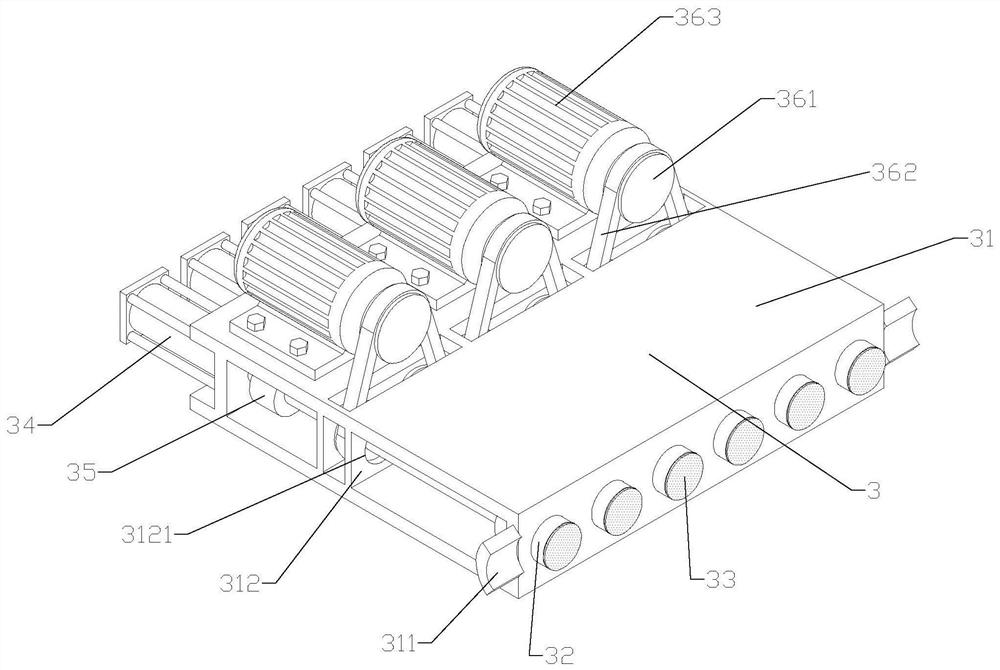

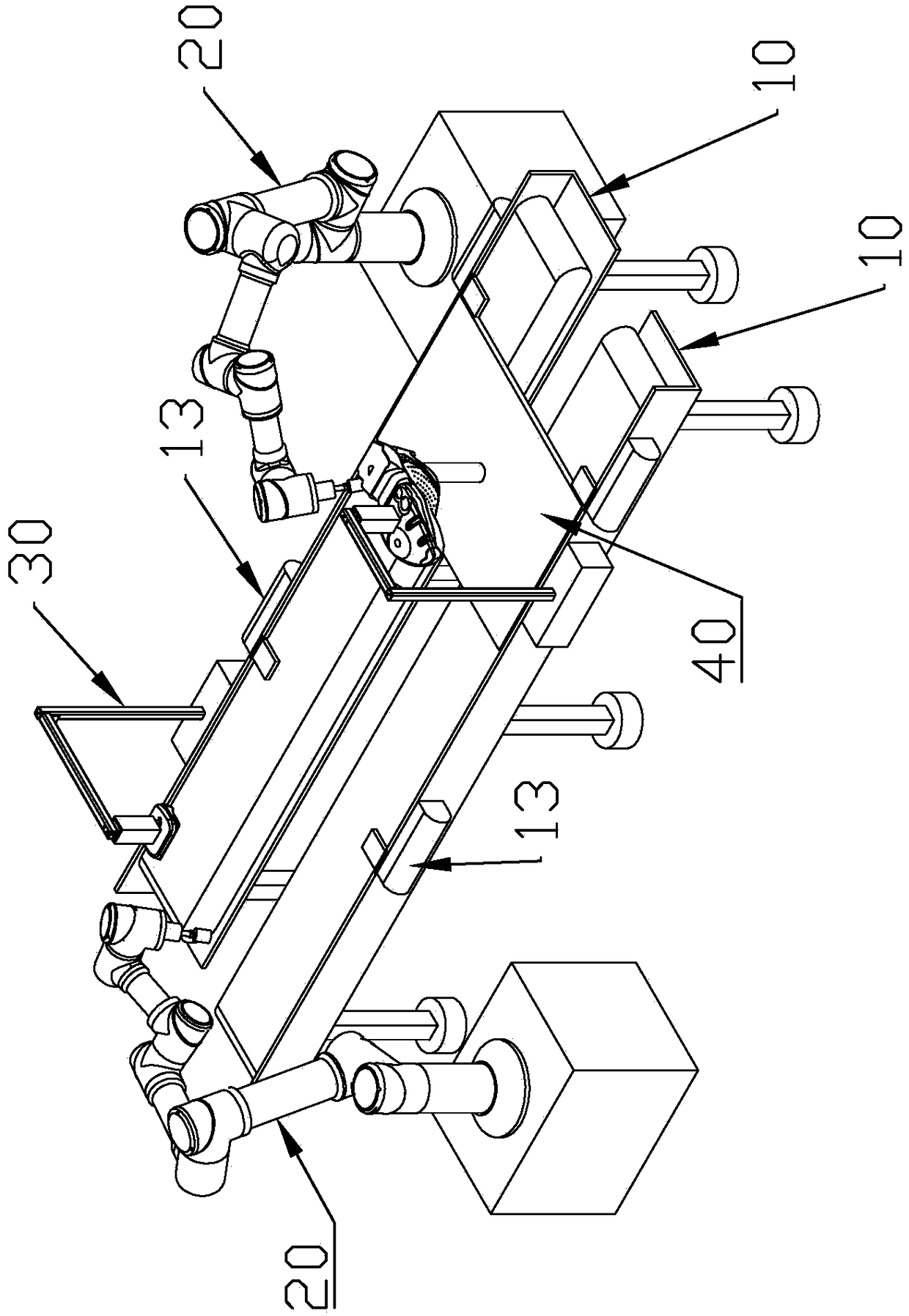

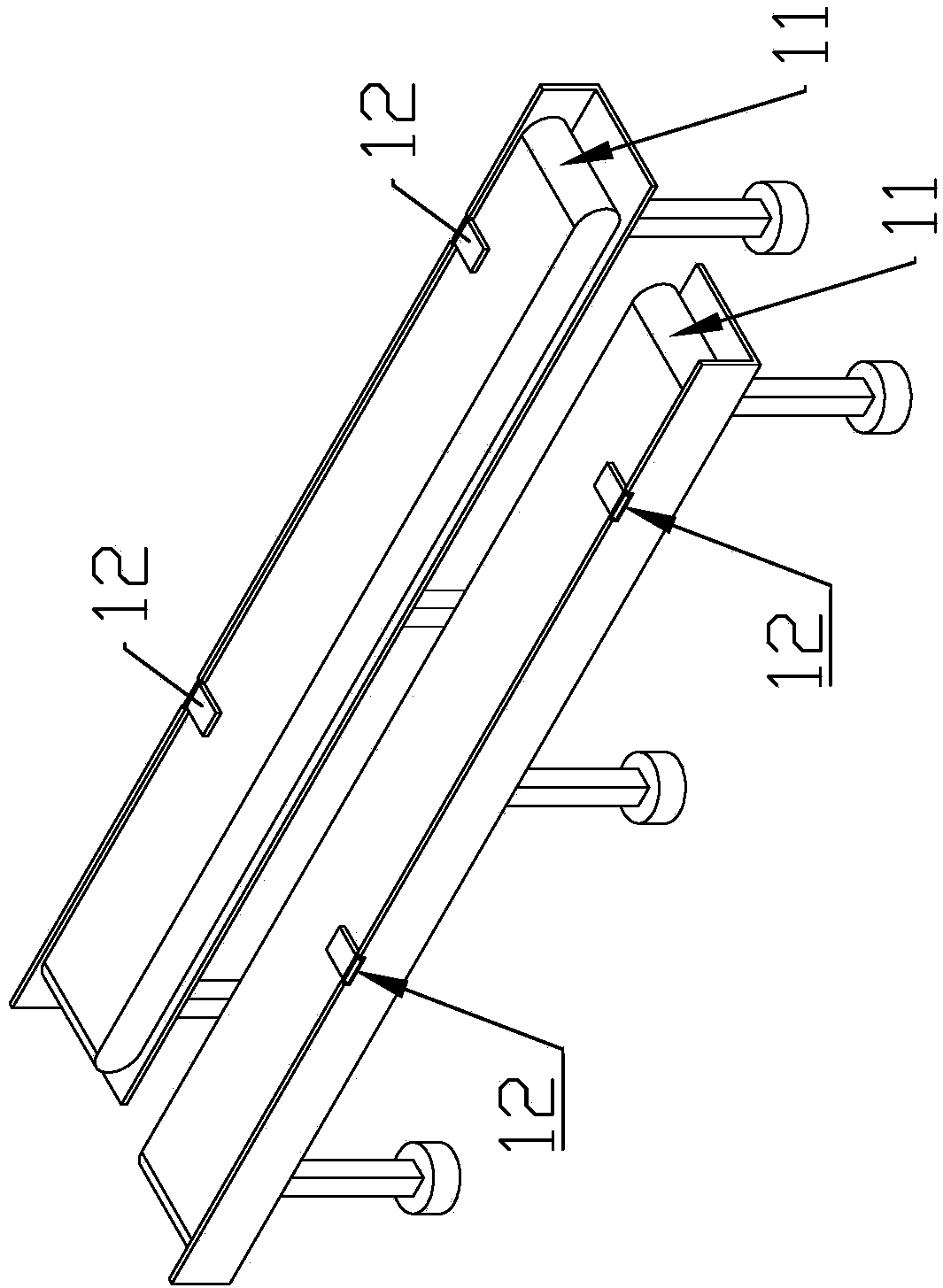

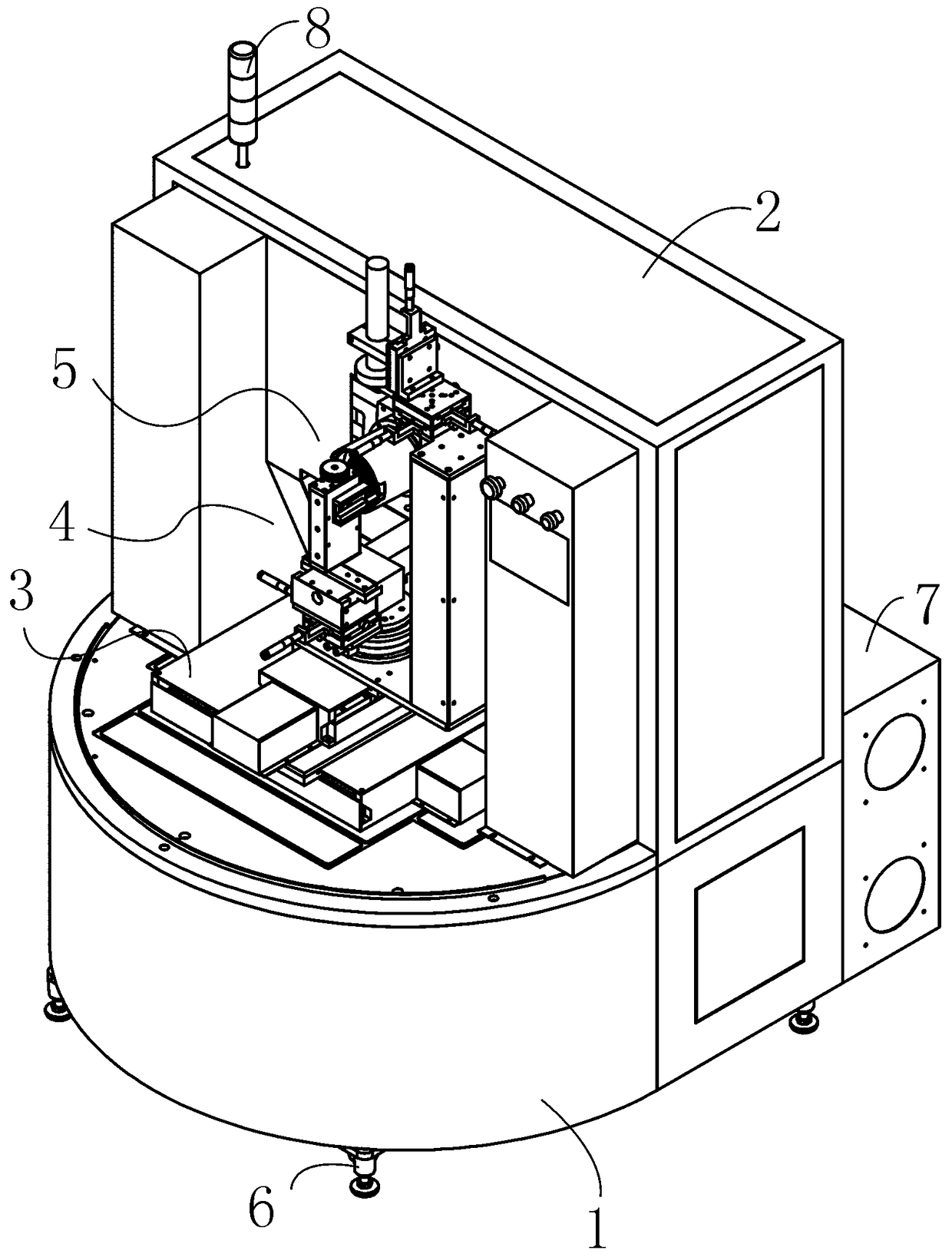

Automatic grinding machine for soles

ActiveCN108851353AReduce grinding errorImprove sanding qualityShoemaking devicesGrinding machinesControl systemEngineering

The invention discloses an automatic grinding machine for soles. The machine comprises a control system, a rack and a conveying device, the two ends of the conveying device are the front sole grindingend and the rear sole grinding end, and mechanical arms are distributed at the front sole grinding end and the rear sole grinding end respectively; all the mechanical arms comprise grinding devices installed at the tail ends, a mounting table is placed on the conveying device, and a lifting top support is distributed on the mounting table; a foot die with an upward sole is distributed at the topof the lifting top support, and sole fixing parts are distributed at the front sole grinding end and the rear sole grinding end respectively. According to the automatic grinding machine, the front sole grinding end and the rear sole grinding end are designed, and sole grinding is divided into two grinding working processes in sequence; through cooperation of the designed sole fixing parts and thedesigned lifting top support, the ascending positions of shoes to be processed can be fixed; positioning baffles are designed, and the positions of the shoes to be processed can be precisely limited.Through the design, the grinding errors can be reduced, the grinding quality is improved, and the automatic grinding machine can be widely applied to the technical field of shoe manufacturing.

Owner:深圳市智能机器人研究院

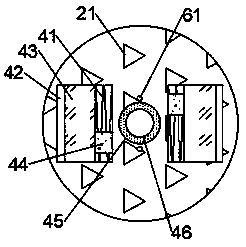

Numerically controlled inner tooth grinding head

InactiveCN100352589CLow costNo interferenceGear teeth manufacturing toolsGear teethEngineeringGrinding wheel

The present invention relates to gear machining equipment, and is especially numerically controlled inner tooth grinding head. The numerically controlled inner tooth grinding head consists of cutter shaft, grinding wheel installing angle regulating mechanism, grinding wheel bearing mechanism and driving force transmission mechanism. The grinding wheel installing angle regulating mechanism consists of the lower arced surface of cutter shaft and the upper arced surface of the grinding wheel support; and the driving force transmission mechanism consists of spring soft shaft and bevel gears. The present invention has the advantages of small grinding error, high grinding precision and smooth running.

Owner:SOUTH CHINA UNIV OF TECH

A Variable Stiffness Compliant Grinding and Polishing Actuator

ActiveCN113001398BConstant stiffnessEasy to GrindGrinding feed controlAutomatic grinding controlSolid woodPolishing

Owner:安徽云章智能科技有限公司

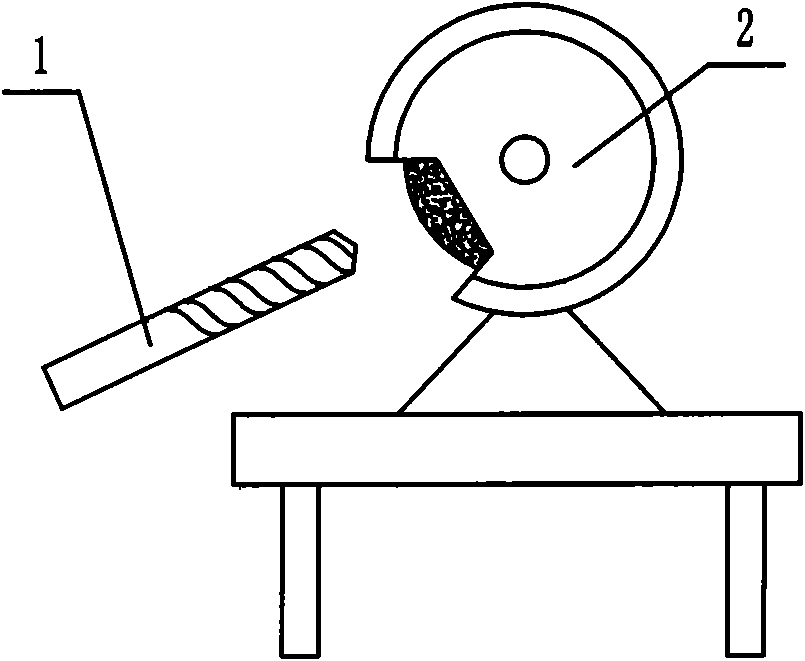

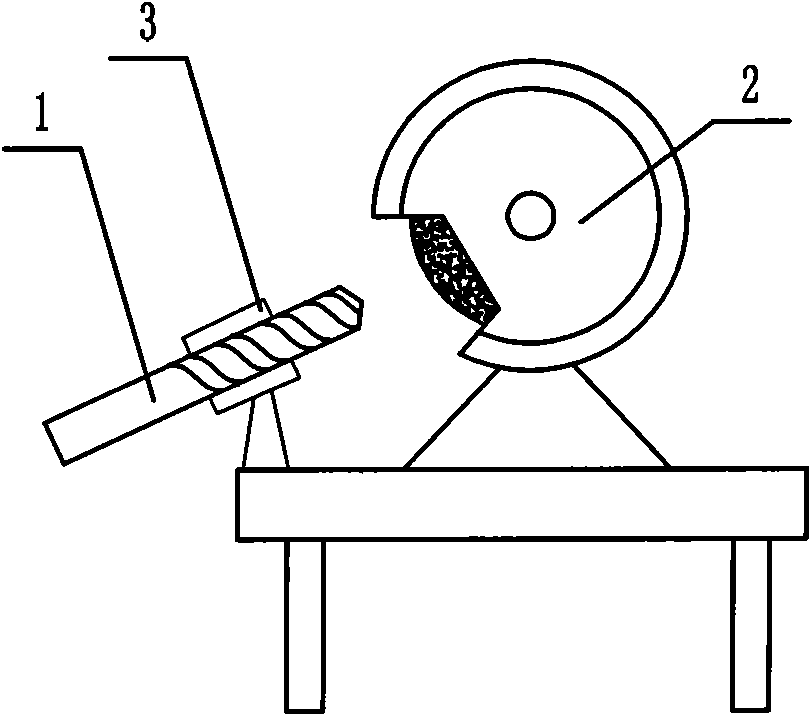

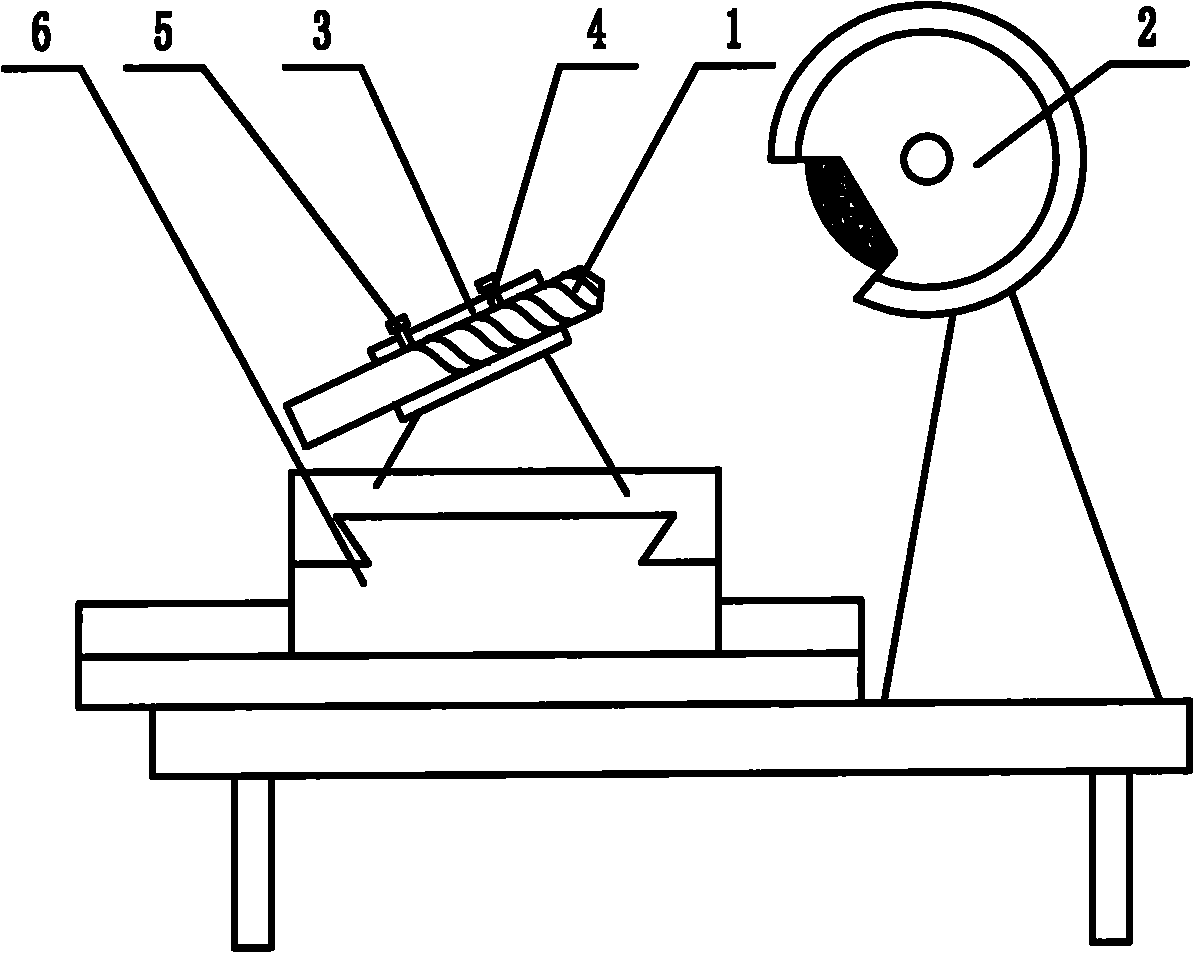

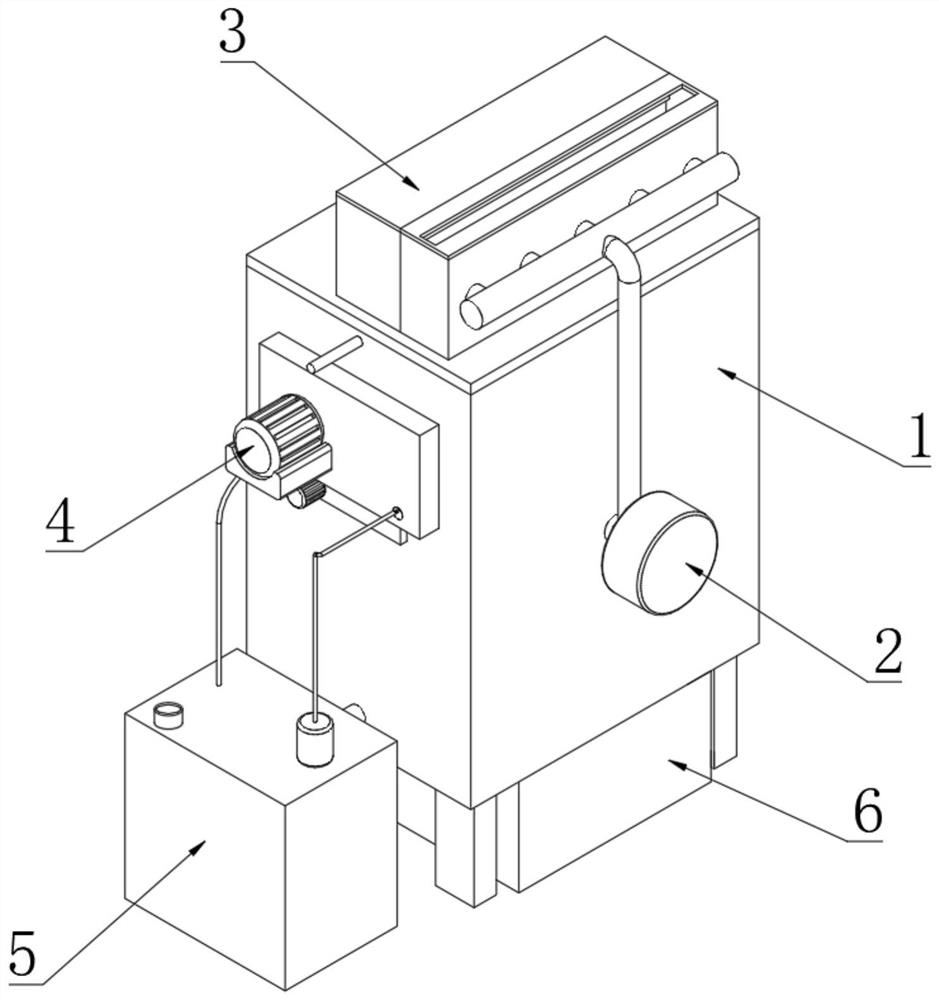

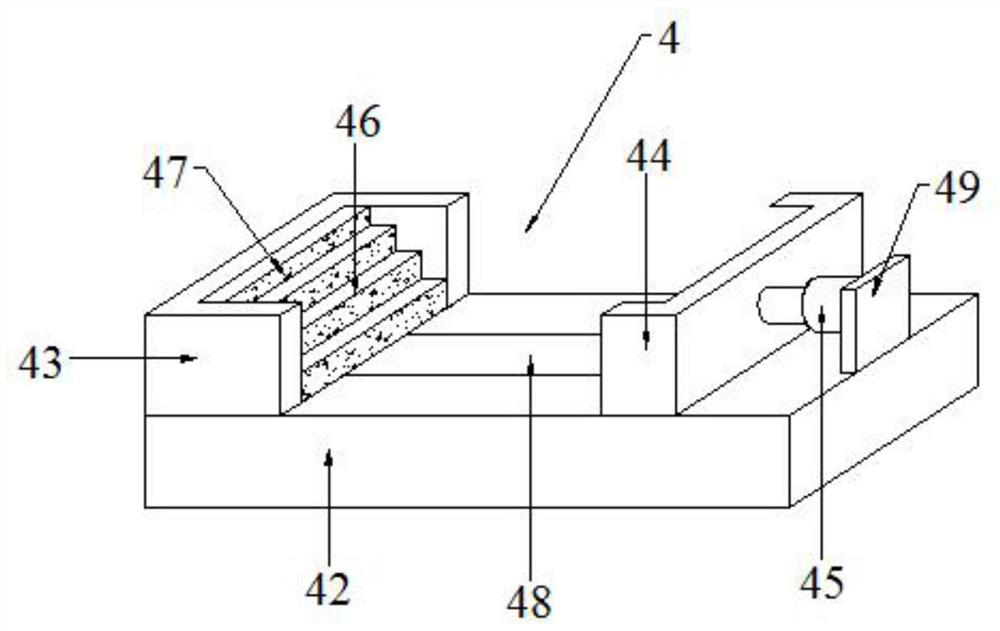

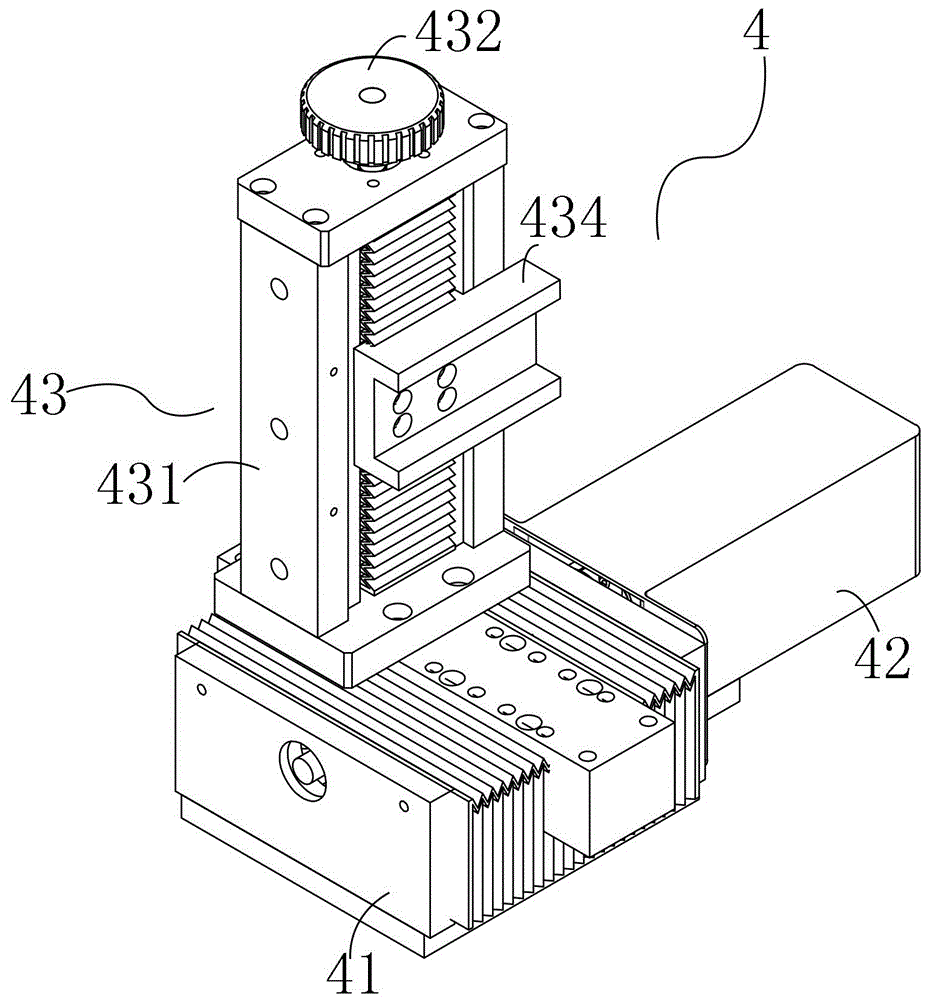

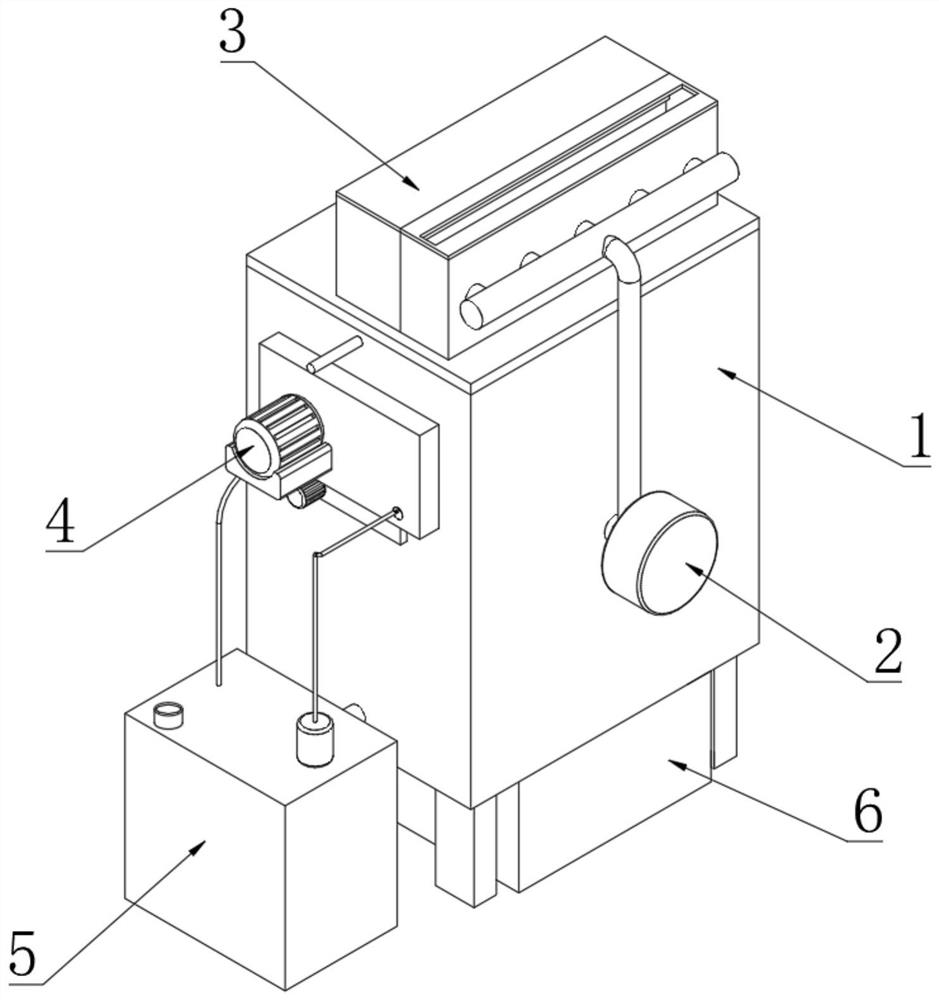

Tool sharpener

ActiveCN106078369AImprove grinding precisionImprove machining accuracyGrinding carriagesGrinding drivesEngineeringMechanical engineering

The present invention provides a tool sharpener comprising a worktable, a vertical worktable, an adjusting platform, a tool sharpening device and a tool clamping device. The adjusting platform is mounted on the worktable. The tool clamping device is mounted on the adjusting platform. The vertical worktable is mounted on the worktable and located behind the adjusting platform. The tool grinding device is mounted on the vertical worktable. The tool sharpener achieves machining to a cutting tool by means of multi-axis control of the adjusting platform, the tool sharpening device and the tool clamping device, thus allowing reduction of manual labor, increase of the tool machining precision, decrease of machining errors, and improvement of the machining efficiency.

Owner:DONGGUAN EZAT AUTOMATION TECH

Fixture structure for grinding ultra-thin single crystal diamond substrate and manufacturing method of fixture structure

The invention relates to the technical field of diamond growth, in particular to a fixture structure for grinding an ultra-thin single crystal diamond substrate and a manufacturing method of the fixture structure. According to the fixture structure for grinding the ultra-thin single crystal diamond substrate and the manufacturing method of the fixture structure, grinding errors can be reduced, simultaneous grinding of a plurality of diamond substrates is facilitated, and the consuming time is reduced. The fixture structure comprises a fixing column, a plurality of sets of supporting plates anda plurality of sets of adjusting threaded rods, wherein a plurality of sets of placing grooves are formed in the top edge area of the fixing column, a plurality of sets of adjusting holes are formedin the bottom edge area of the fixing column, and the adjusting holes correspondingly communicate with the placing grooves; and internal threads corresponding to the adjusting threaded rods are arranged on the inner walls of the adjusting holes, and a plurality of sets of rotating plates are correspondingly arranged at the bottom ends of the adjusting threaded rods. The manufacturing method of thefixture structure comprises the following steps that (1) grooving treatment is carried out; (2) thread turning is carried out; (3) waste chips are cleaned; (4) anti-slip mats and cushions are pasted;(5) floating glue is cleaned; (6) the threaded rods are installed; (7) scales are drawn; and (8) welding treatment is carried out.

Owner:西安碳星半导体科技有限公司

Burr trimming machine for blockboard processing

ActiveCN113547409AAngle adjustableReduce grinding errorEdge grinding machinesGrinding work supportsPolishingWood plank

The invention is applicable to the technical field of wood board processing, and provides a burr trimming machine for blockboard processing. The burr trimming machine comprises a support base frame, a trimming guide assembly and a trimming assembly, wherein the trimming assembly comprises a fixed shell, a rotating shell and a polishing roller. Through the arrangement that the trimming guide assembly is matched with the trimming assembly, the purpose that the trimming assembly is guided by the trimming guide assembly to be matched with a blockboard for polishing along a certain path is achieved, movement of the burr trimming machine does not need to be manually controlled, and polishing errors in the trimming process are reduced; and meanwhile, through the arrangement of the three-section combined trimming assembly, the included angle of the polishing roller is adjustable, so that the trimming machine can adapt to polishing and trimming of more blockboards with different corner specifications through adjustment, the burr trimming machine is more convenient to use, and the problem that in the prior art, the adjacent surfaces need to be repeatedly polished in a reciprocating manner is solved.

Owner:江苏德鲁尼智能家居有限公司

a sharpener

ActiveCN106078369BImprove grinding precisionImprove machining accuracyGrinding carriagesGrinding drivesMulti axisMachining

The present invention provides a tool sharpener comprising a worktable, a vertical worktable, an adjusting platform, a tool sharpening device and a tool clamping device. The adjusting platform is mounted on the worktable. The tool clamping device is mounted on the adjusting platform. The vertical worktable is mounted on the worktable and located behind the adjusting platform. The tool grinding device is mounted on the vertical worktable. The tool sharpener achieves machining to a cutting tool by means of multi-axis control of the adjusting platform, the tool sharpening device and the tool clamping device, thus allowing reduction of manual labor, increase of the tool machining precision, decrease of machining errors, and improvement of the machining efficiency.

Owner:DONGGUAN EZAT AUTOMATION TECH

A kind of preparation method of heat conduction insulation silicone grease

ActiveCN111841719BScientific and reasonable structureEasy to useGrain treatmentsRotational axisEngineering

The invention discloses a method for preparing heat-conducting and insulating silicone grease, which comprises a grinding box. Mounting rods are installed between the inner walls of the grinding box through screws. Both ends of the mounting rods are provided with T-shaped grooves. The inside of the swaying groove is slidingly connected with a swaying plate, the outer middle of the rotating shaft is fixedly sleeved with a protruding rod, both ends of the top surface of the filter are welded with protruding blocks, one end of the grinding box is installed with a fan, and one end of the fan is at the bottom of the two bearing plates There are blowing pipes connected to the end positions. Compared with the prior art, the invention makes the ground product move in an inclined arc, so that the product is evenly dispersed, and the purpose of uniform feeding is achieved. The problem of blockage at the bottom of the grinding box occurs, so that The incompletely ground raw material forms an arc-shaped backflow, and through the arc-shaped backflow, it can enter between the two grinding rollers along the tangential direction of the falling raw material, improving the quality and efficiency of grinding, and avoiding the problem of incomplete grinding.

Owner:苏州晶之电科技有限公司

Automatic sole grinding machine

ActiveCN108851353BReduce grinding errorImprove sanding qualityShoemaking devicesGrinding machinesControl systemMachine

The invention discloses an automatic grinding machine for soles. The machine comprises a control system, a rack and a conveying device, the two ends of the conveying device are the front sole grindingend and the rear sole grinding end, and mechanical arms are distributed at the front sole grinding end and the rear sole grinding end respectively; all the mechanical arms comprise grinding devices installed at the tail ends, a mounting table is placed on the conveying device, and a lifting top support is distributed on the mounting table; a foot die with an upward sole is distributed at the topof the lifting top support, and sole fixing parts are distributed at the front sole grinding end and the rear sole grinding end respectively. According to the automatic grinding machine, the front sole grinding end and the rear sole grinding end are designed, and sole grinding is divided into two grinding working processes in sequence; through cooperation of the designed sole fixing parts and thedesigned lifting top support, the ascending positions of shoes to be processed can be fixed; positioning baffles are designed, and the positions of the shoes to be processed can be precisely limited.Through the design, the grinding errors can be reduced, the grinding quality is improved, and the automatic grinding machine can be widely applied to the technical field of shoe manufacturing.

Owner:深圳市智能机器人研究院

Method for grinding spherical surface of workpiece

InactiveCN102672576BReduce grinding errorReduce processing costsSpherical surface grinding machinesGrinding work supportsEngineeringGrinding wheel

The invention discloses a method for grinding the spherical surface of a workpiece. According to the method, the workpiece is coaxially and fixedly arranged at the clamping end of a clamping rotating shaft, so that the spherical center of the spherical surface to be machined on the workpiece is coincided with the revolving center of a revolving mechanism; during grinding, the clamping rotating shaft is driven by the revolving mechanism to do centering swing around the revolving center of the revolving mechanism, and the clamping rotating shaft is driven by a rotating shaft driving mechanism to drive the workpiece to rotate around the revolving central axis of the clamping rotating shaft; and a grinding wheel rotates around the revolving central axis of the grinding wheel, and a grinding working surface of the grinding wheel contacts the outer peripheral surface of the spherical surface to be machined on the workpiece to grind the workpiece. By the method, grinding errors are reduced effectively, and grinding accuracy is improved. In addition, the method for grinding the spherical surface is safe, reliable, simple, convenient, high in grinding efficiency and low in machining cost, and has high application value.

Owner:HENAN UNIV OF SCI & TECH

Automatic polisher

PendingCN107695820AAvoid shaking situationsGuaranteed stabilityEdge grinding machinesElectric machinePolishing

The invention discloses an automatic polisher. The automatic polisher comprises a polisher body. The polisher body comprises a positioning device, a polishing device and a main control module. The positioning device comprises a pot bottom supporting frame, a pot mouth positioning frame and a rotating motor. An optoelectronic switch used for inspecting a liner shell is arranged on the pot bottom supporting frame. The polishing device is arranged on one side of the pot bottom supporting frame and moves back and forth in the direction perpendicular to the pot bottom supporting frame. The rotatingmotor and the optoelectronic switch are independently connected with the main control module. The automatic polisher can automatically carry out good polishing treatment on liner shells, the polishing efficiency can be improved, the polishing errors can be reduced, and it is guaranteed that no burrs which affect the welding effect exist on the edges of liner shells.

Owner:江门市丰荣金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com