A kind of preparation method of heat conduction insulation silicone grease

A heat-conducting insulation and silicone grease technology is applied in the field of preparation of heat-conducting and insulating silicone grease. and speed, effects that increase effectiveness and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

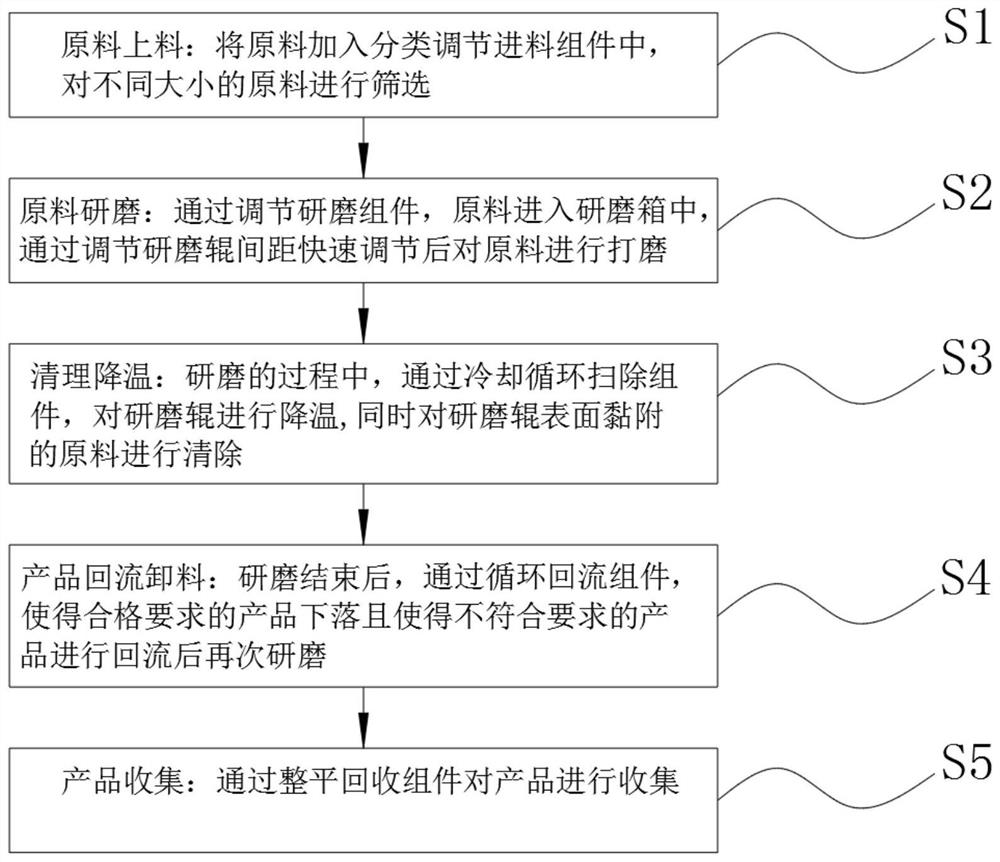

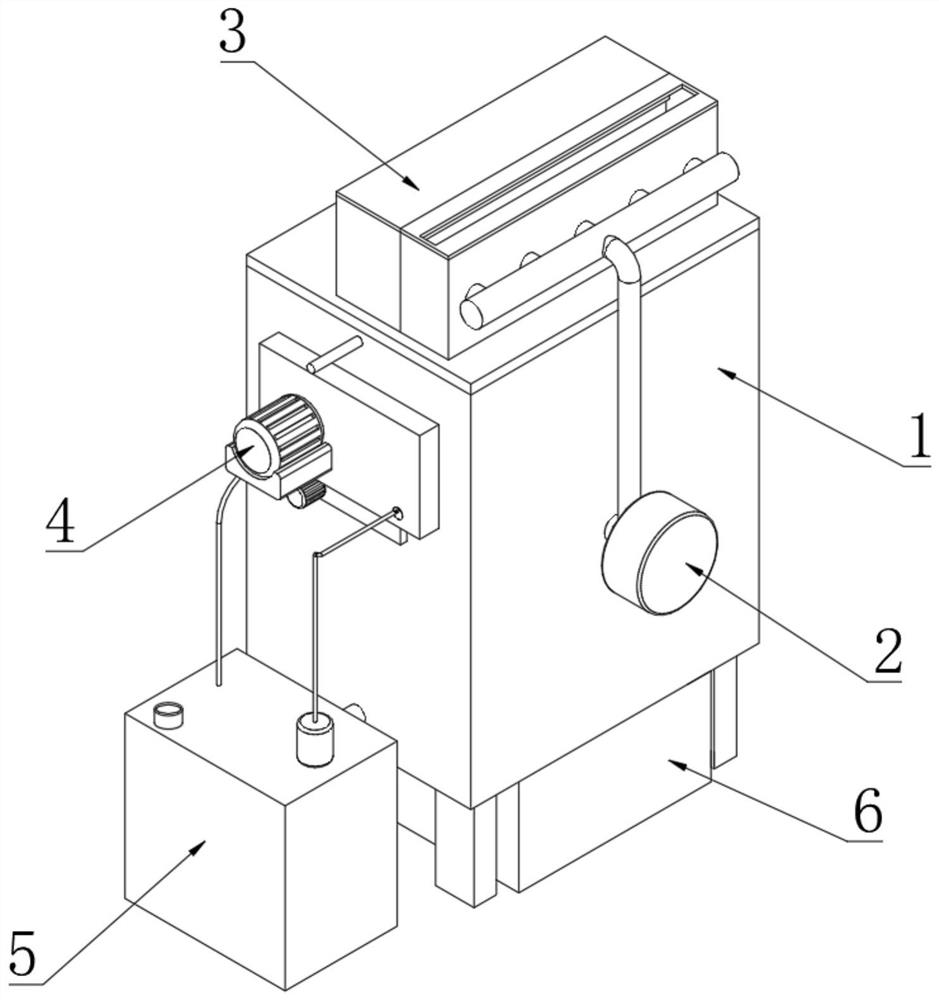

[0042] Example: The figure 1 , The present invention provides a technical solution of a thermally conductive insulating grease production method, comprising the steps of:

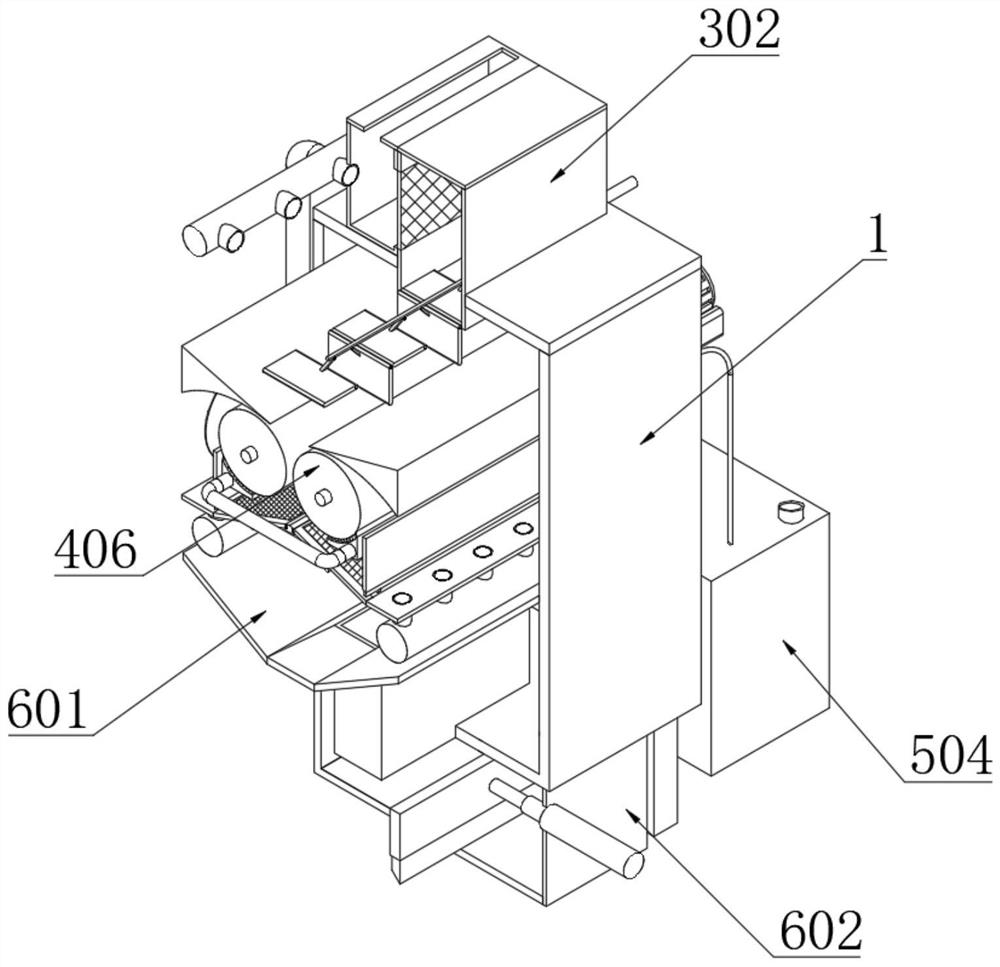

[0043] Sl, the raw material: The classified material was added adjusting the feed assembly 3, a raw material for different sizes of screening.

[0044] S2, polishing material: 4 by adjusting the grinding assembly, into the feed tank triturated 1, after grinding the raw material quickly adjusted by adjusting the spacing of the grinding roller 406;

[0045] S3, clean cooling: the grinding process, the cleaning unit 5 through a cooling cycle, the roller 406 to cool the polishing, the surface of the polishing roller 406 while the adhesive material is cleared.

[0046] Polished after polishing again, by the circulation flow member 2, so that the falling product qualification requirements and such products do not meet the requirements for reflux;: S4, the discharge product return

[0047] S5, product collection: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com