Polishing machine capable of conveniently polishing powder metallurgy mold cavity

A powder metallurgy and polishing machine technology, applied in the field of polishing machines, can solve the problems of excessive grinding cavity, sticking mold products, damage, etc., and achieve the effect of reducing grinding errors, high applicability, and improving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

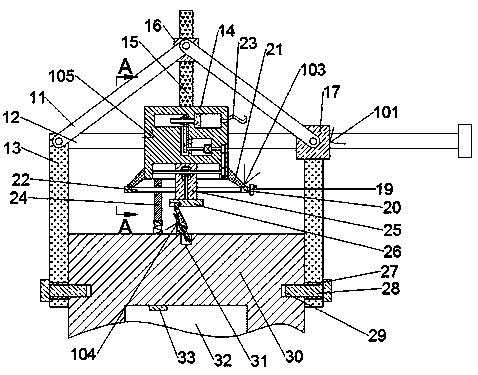

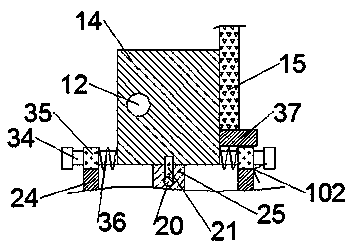

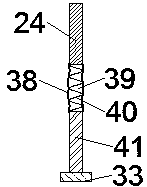

[0019] Combine below Figure 1-6 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0020] refer to Figure 1-6 , according to an embodiment of the present invention, a polishing machine for grinding powder metallurgy mold cavity, comprising a body 14 and a first T-shaped slide bar 12, the first T-shaped slide bar 12 runs through the inner wall of the body 14, The first T-shaped slide bar 12 is slidably connected with the body 14, and the outer circumference of the first T-shaped slide bar 12 is provided with the first T-shaped slide bar 12 to be fixed on the left and right sides of the mold 30, And it can rotate back and forth to adjust a certain angle, and can make the body 14 always be in the fixing mechanism 101 in the middle position of the mold 30, and the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com