Method for grinding spherical surface of workpiece

A technology of workpiece and working surface, which is applied in the field of grinding spherical surface processing on the end or part of the workpiece, can solve the problems of poor grinding efficiency and low grinding accuracy, and achieves improved grinding accuracy, high grinding efficiency, The effect of high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

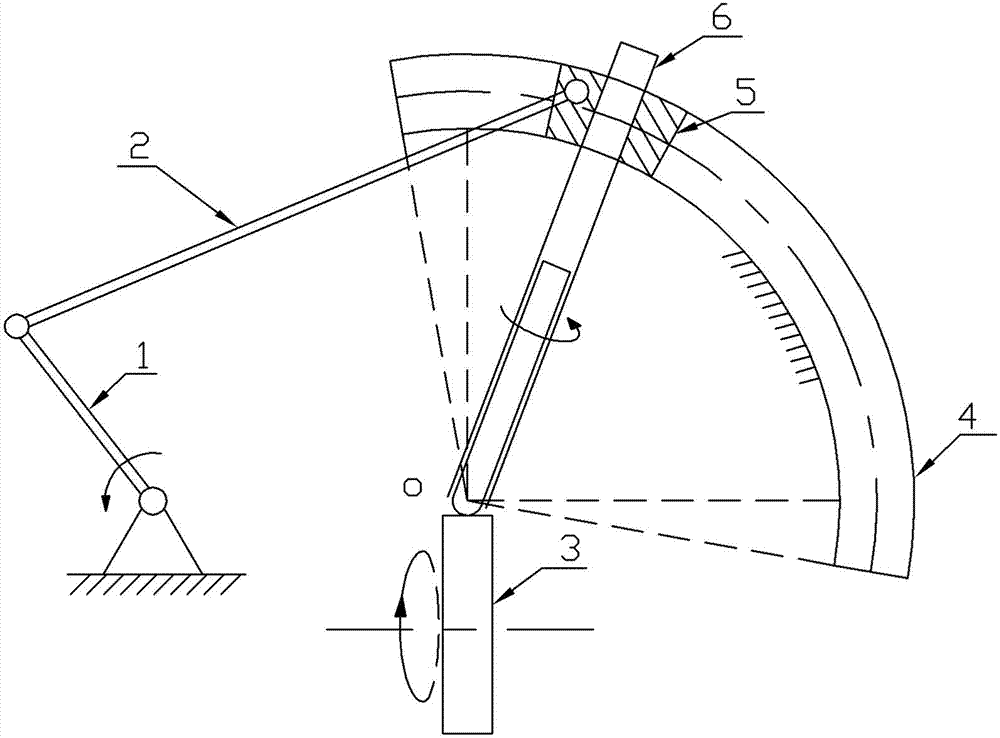

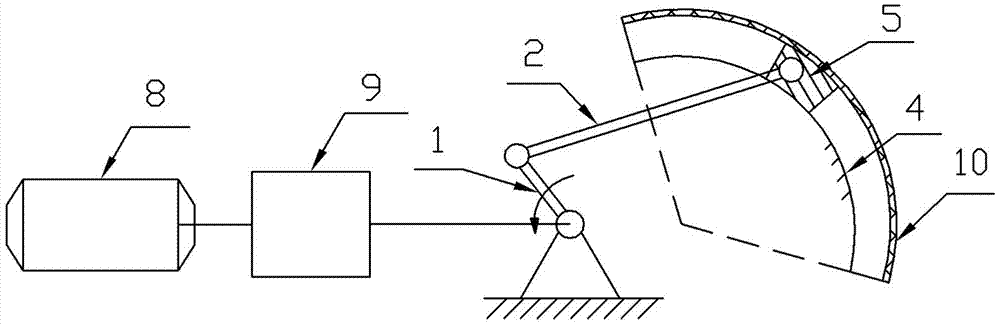

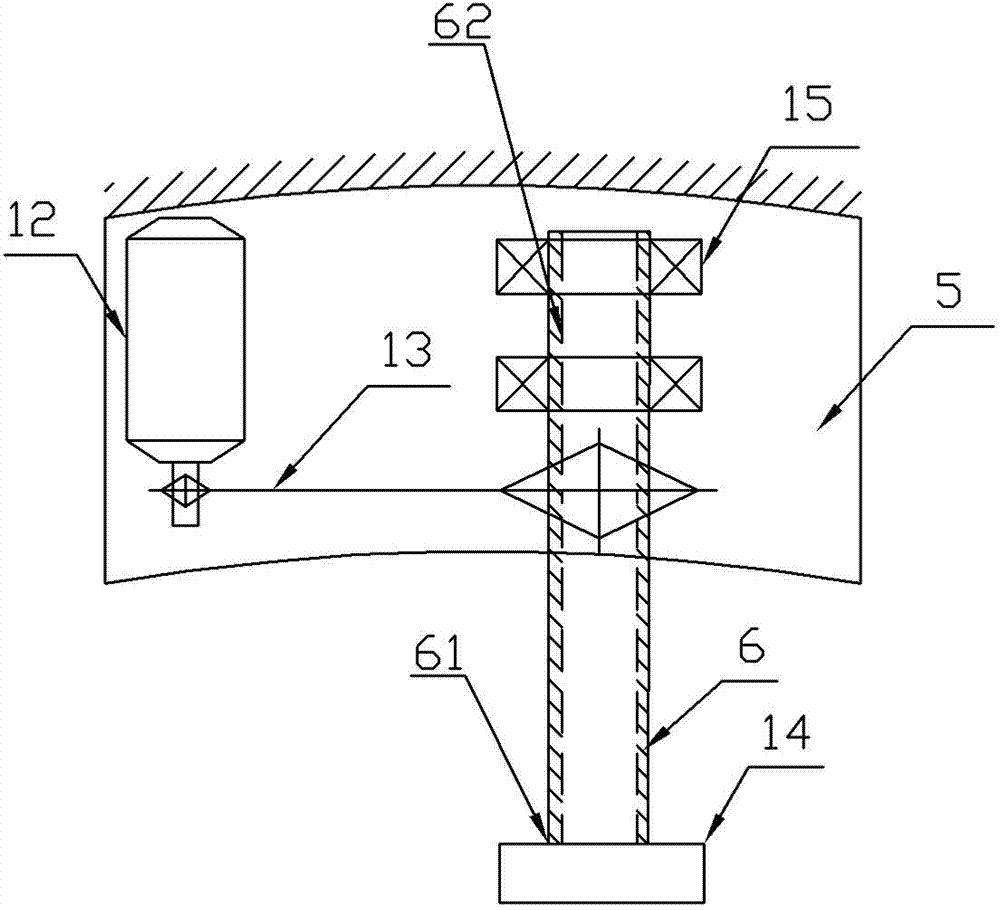

[0018] The method of grinding spherical surface provided by the present invention adopts such as Figure 1 to Figure 4 The ball grinding device in the shown embodiment, this workpiece grinding method is to use the chuck 14 to fix the workpiece 7 coaxially on the clamping end 61 of the clamping shaft 6, so that the surface of the spherical surface to be processed on the workpiece 7 The center of the sphere coincides with the center of rotation of the slewing mechanism. During grinding, the slewing mechanism drives the clamping shaft 6 to swing around the center of gyration of the slewing mechanism, and the clamping shaft 6 drives the workpiece 7 to rotate around the center of gyration Centering and swinging, at the same time, the clamping shaft 6 is driven by the shaft drive mechanism to drive the workpiece 7 to rotate around the central axis of rotation of the clamping shaft 6, and the grinding wheel 3 rotates around the central axis of rotation, and then the grinding surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com