A peripheral grinding wheel for rough and fine grinding of pcbn blades

A grinding wheel and grinding wheel technology, applied in the direction of bonding grinding wheels, abrasives, metal processing equipment, etc., can solve the problems of unreasonable grinding wheel structure design, inability to solve technical problems, and increase the configuration of machine tools, so as to achieve reasonable grinding wheel structure design, The effect of improving grinding efficiency and reducing the amount of configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further explained in conjunction with the accompanying drawings and specific examples, but is not limited as the present invention.

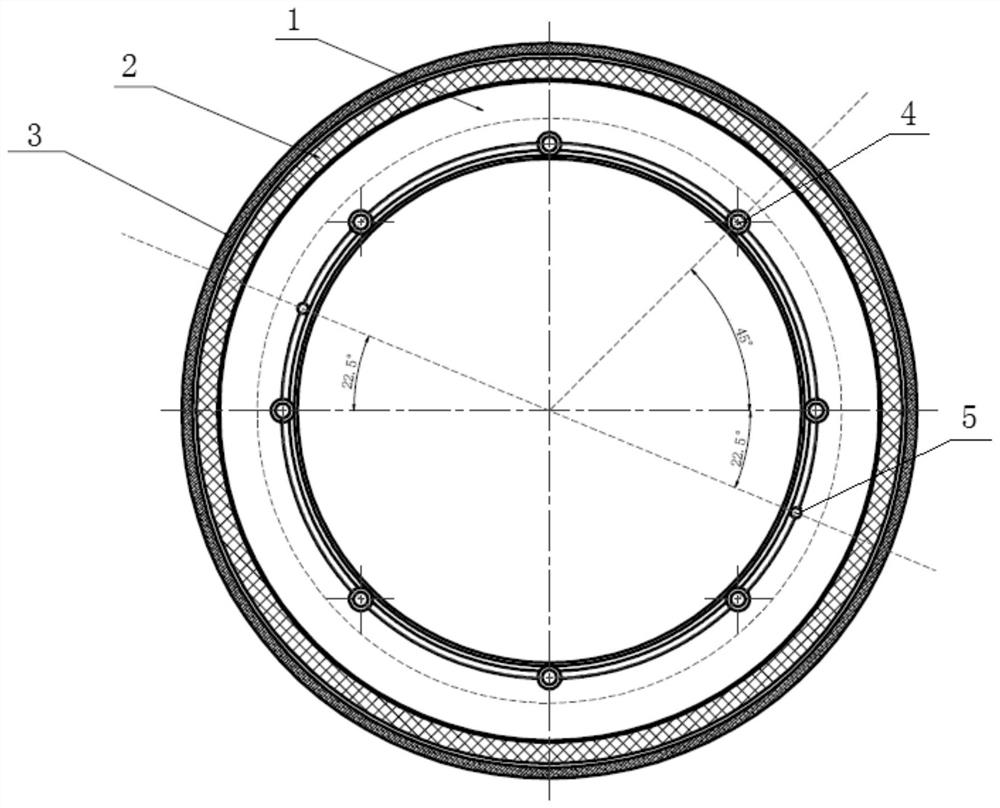

[0016] See figure 1 As shown, the peripheral polishing wheel for the PCBN blade coarse grinding includes a grinding wheel body 1 and an abrasive layer on the outer ring surface of the grinding wheel body 1, and the abrasive layer is bonded to the outer ring surface of the grinding wheel body 1 through the ceramic bonding agent. The abrasive layer is a fine particulate diamond mill or a coarse particulate diamond abrasive layer. The abrasive layer includes a first abrasive layer 2 and a second abrasive layer 3, and the second abrasive layer 3 covers the outer ring surface of the first abrasive layer 2 such that the first abrasive layer 2 is exposed, the first abrasive layer 2 is a crude particulate diamond The abrasive layer, the second abrasive layer 3 is a fine particulate diamond abrasive layer, and the axial center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com