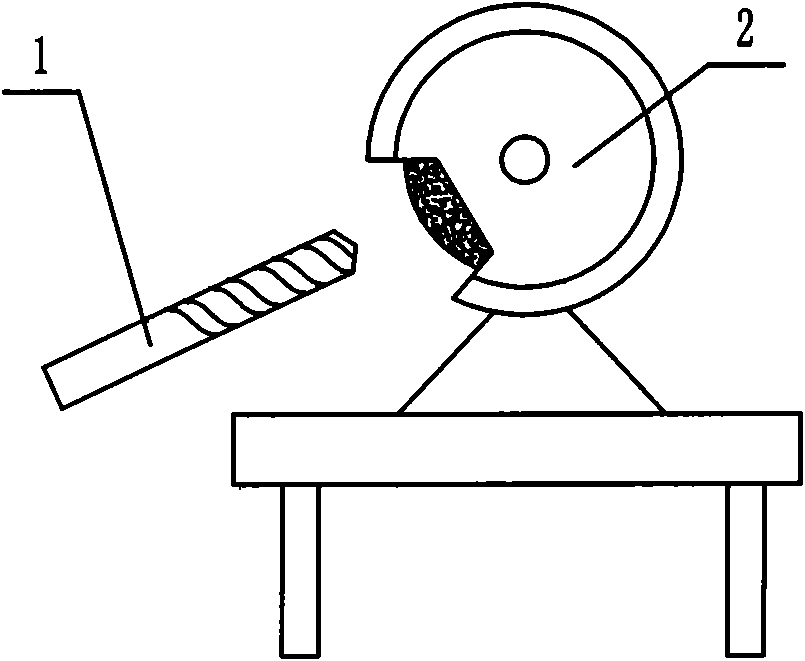

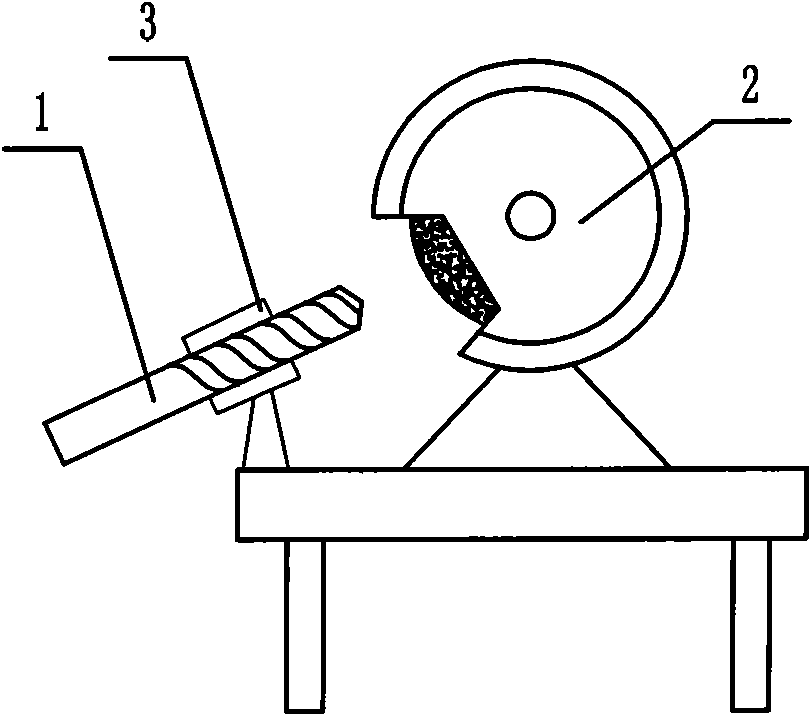

Numerical control drill double relief angle blade milling machine

A sharpening machine and drill bit technology, which is applied in the direction of twist drills, drilling tool accessories, drilling/drilling equipment, etc., can solve the problems of grinding wheel breakage, easy accidents, and large size error of the back angle of the drill bit, and achieve complete shape correction. Consistent, good equipment safety, low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

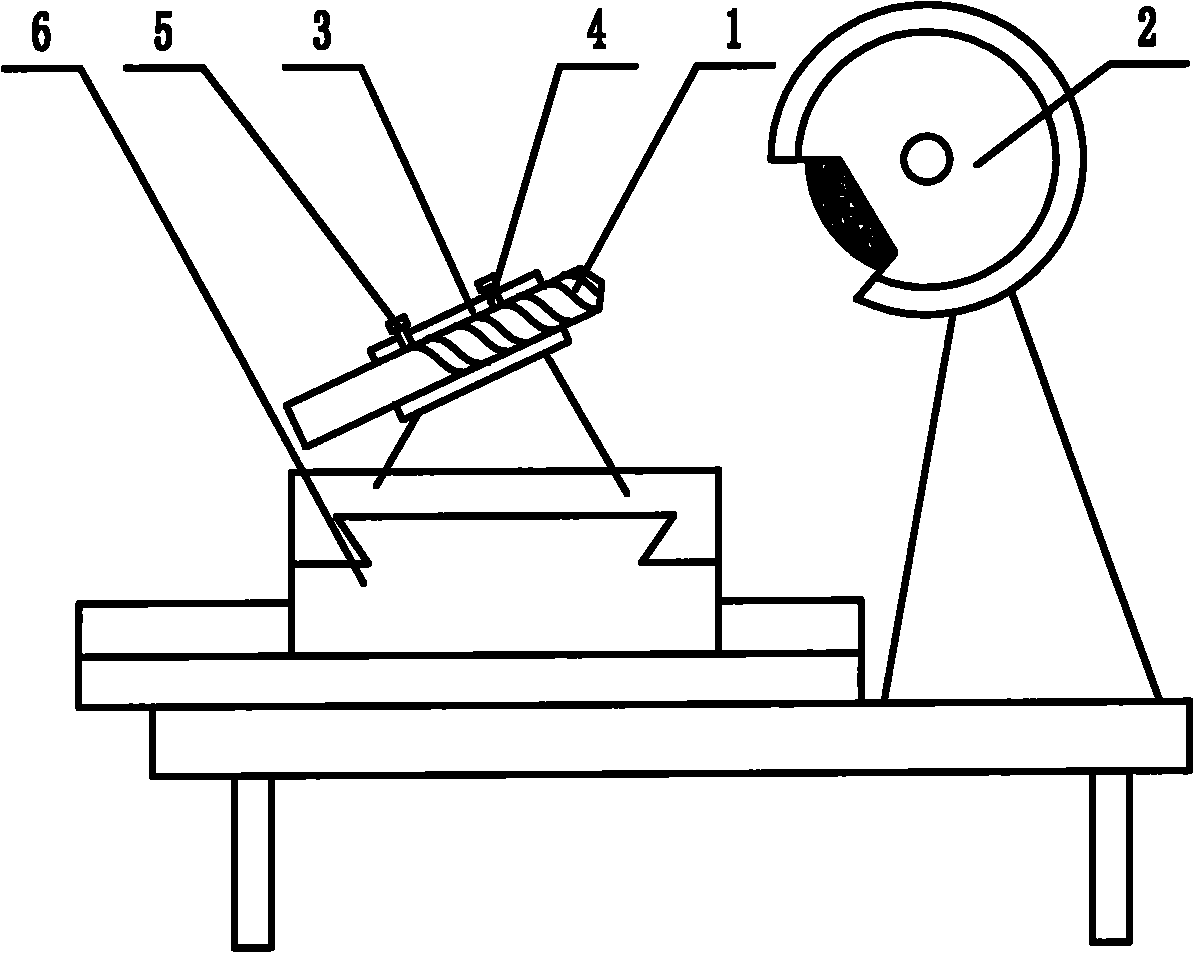

[0015] see Figure 4 to Figure 5 , The present invention has a frame 10, an electric control cabinet 11, a hydraulic device 12, an operation panel 13, and a lubrication device 14. It also has a grinding wheel device 20, a grinding wheel feed device 30, a grinding wheel compensation device 40, a grinding wheel dressing device 50, and automatic feeding The device 60, the drill bit clamping device 70, the chuck feed device 80, and the detection sensor 91 for indexing and positioning the processed drill.

[0016] The grinding wheel device 20 is arranged on the frame and includes a grinding wheel frame 21, a grinding wheel 22 and a driving motor 23 for driving the grinding wheel to rotate. The grinding wheel frame is fixedly installed on the frame, and the grinding wheel and the grinding wheel frame are adjustablely connected. The grinding wheel feeding device 30 is arranged on the grinding wheel frame, and includes a grinding wheel feeding cylinder 31 that drives the grinding wheel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com