Size grading measuring tool

A measuring tool and size technology, which is applied in the direction of manufacturing tools, mechanical gap measurement, measuring/indicating equipment, etc., can solve the problem of reducing the production quality of integral flange plunger sleeves, accurately controlling the feed rate of grinding tools, and the error of grinding results Larger problems, to achieve the requirements of reducing the length, reduce the grinding error, and ensure the effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

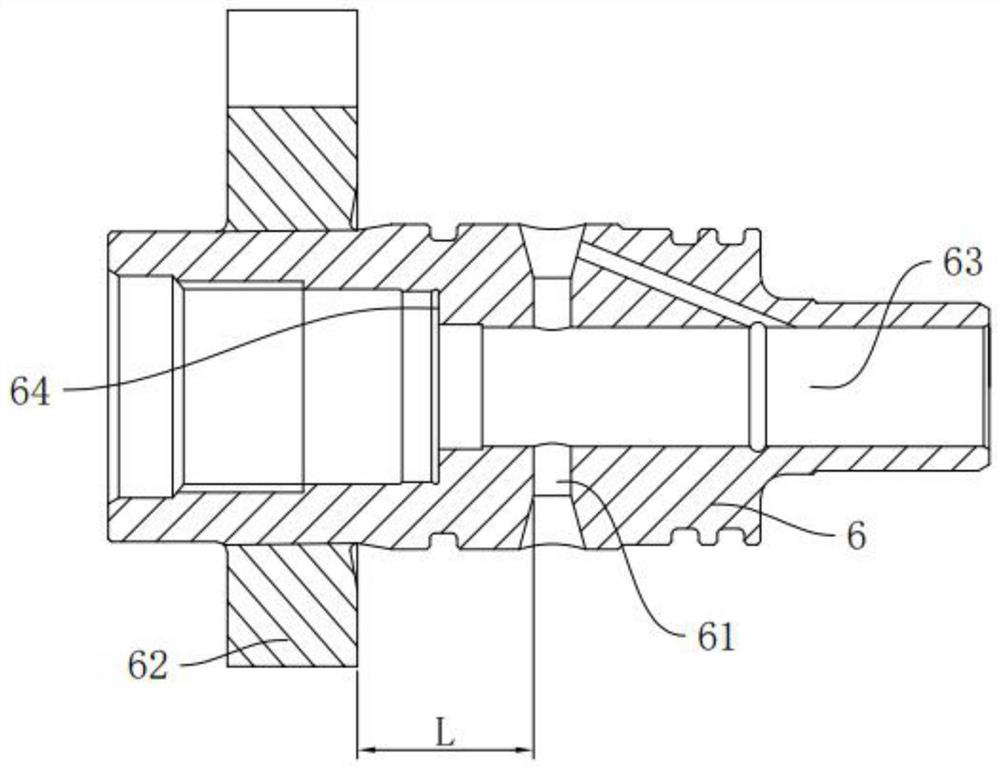

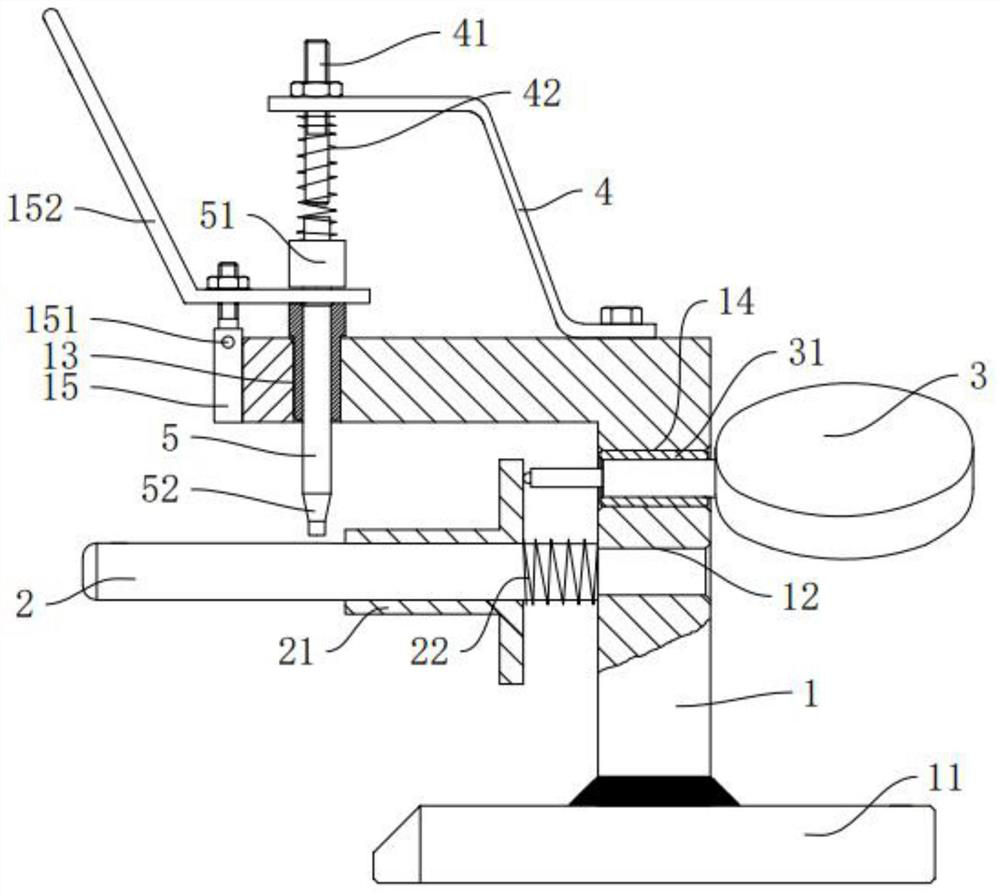

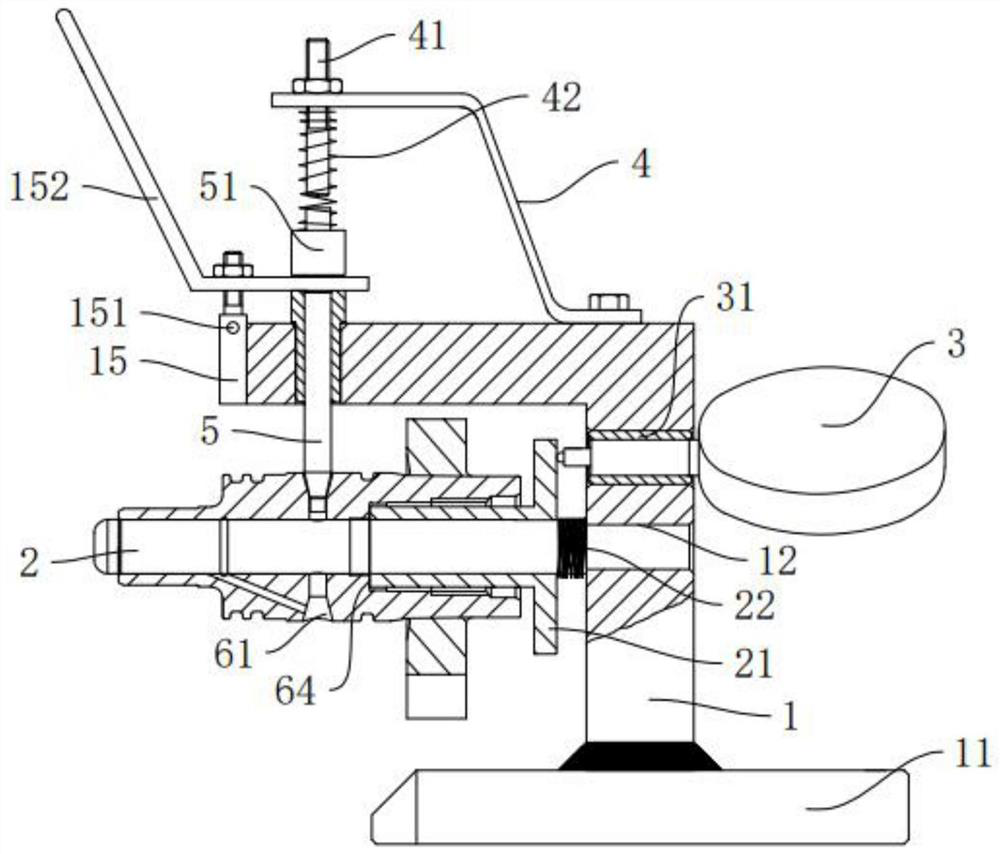

[0035] Please refer to figure 2 and image 3 , the application provides a size grading measuring tool, which includes a bracket 1, and the bracket 1 is provided with:

[0036] The slider 2, the slider 2 is used to support the body 6 to be tested, and allow the body 6 to slide relative to the bracket 1, and the sliding direction of the body 6 is parallel to the axis of the body 6;

[0037] The positioning part 5 is slidably matched with the bracket 1, the sliding direction of the positioning part 5 is perpendicular to the sliding direction of the body 6, and the positioning part 5 is plugged and matched with the oil hole 61;

[0038] The dial gauge 3 is relatively fixed to the bracket 1 , and the axis of the measuring rod of the dial gauge 3 is parallel to the sliding direction of the body 6 . When the body 6 to be tested is placed on the sliding part 2, the measuring head of the dial indicator 3 is against the mounting surface 64, so that when the positioning part 5 is inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com