Automatic grinding machine for soles

A grinding machine and machine technology, which is applied in the direction of shoemaking machinery, grinding machine parts, grinding machines, etc., can solve the problems of high labor intensity, harm to human health, low efficiency, etc., and achieve the goal of improving grinding quality and reducing grinding errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

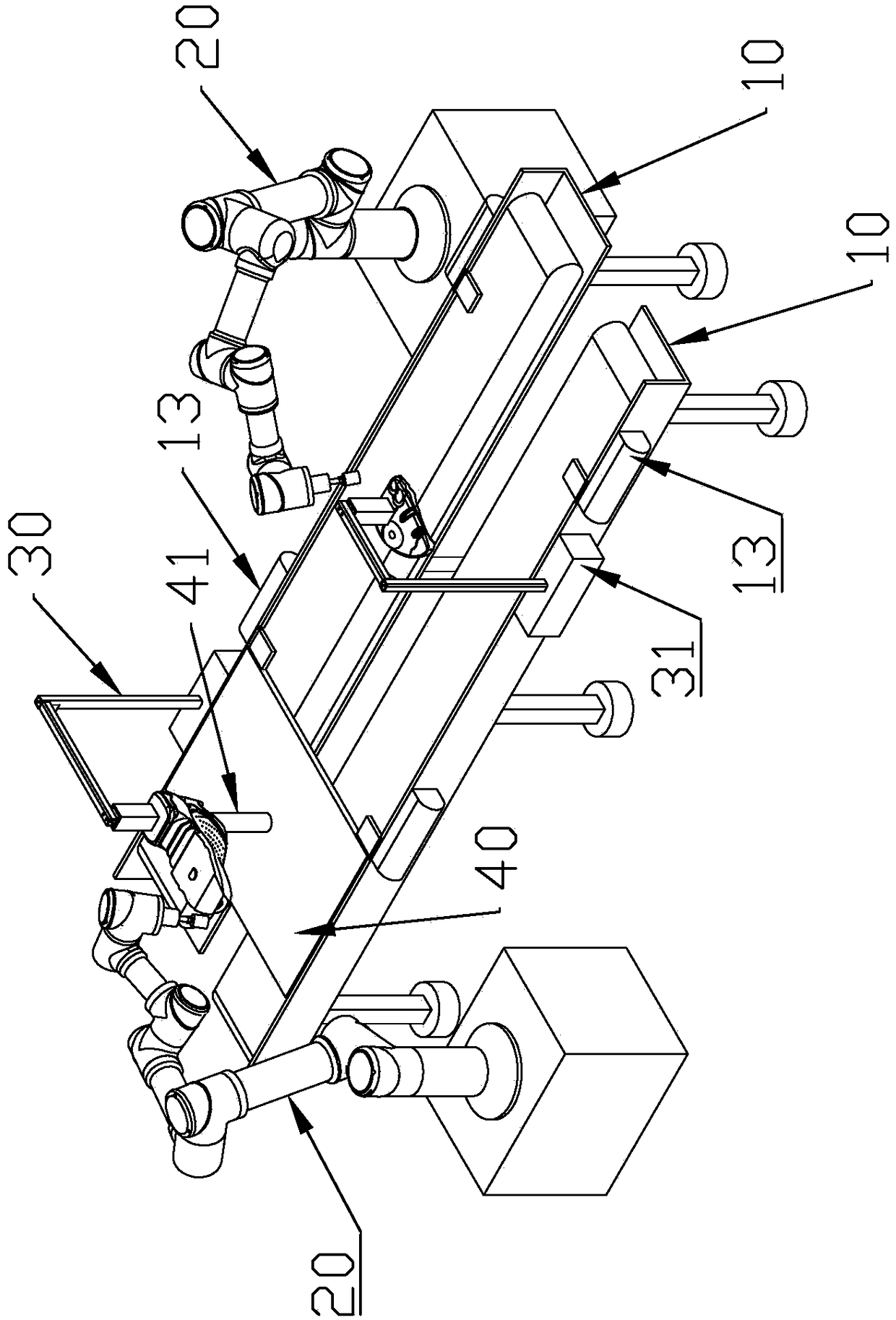

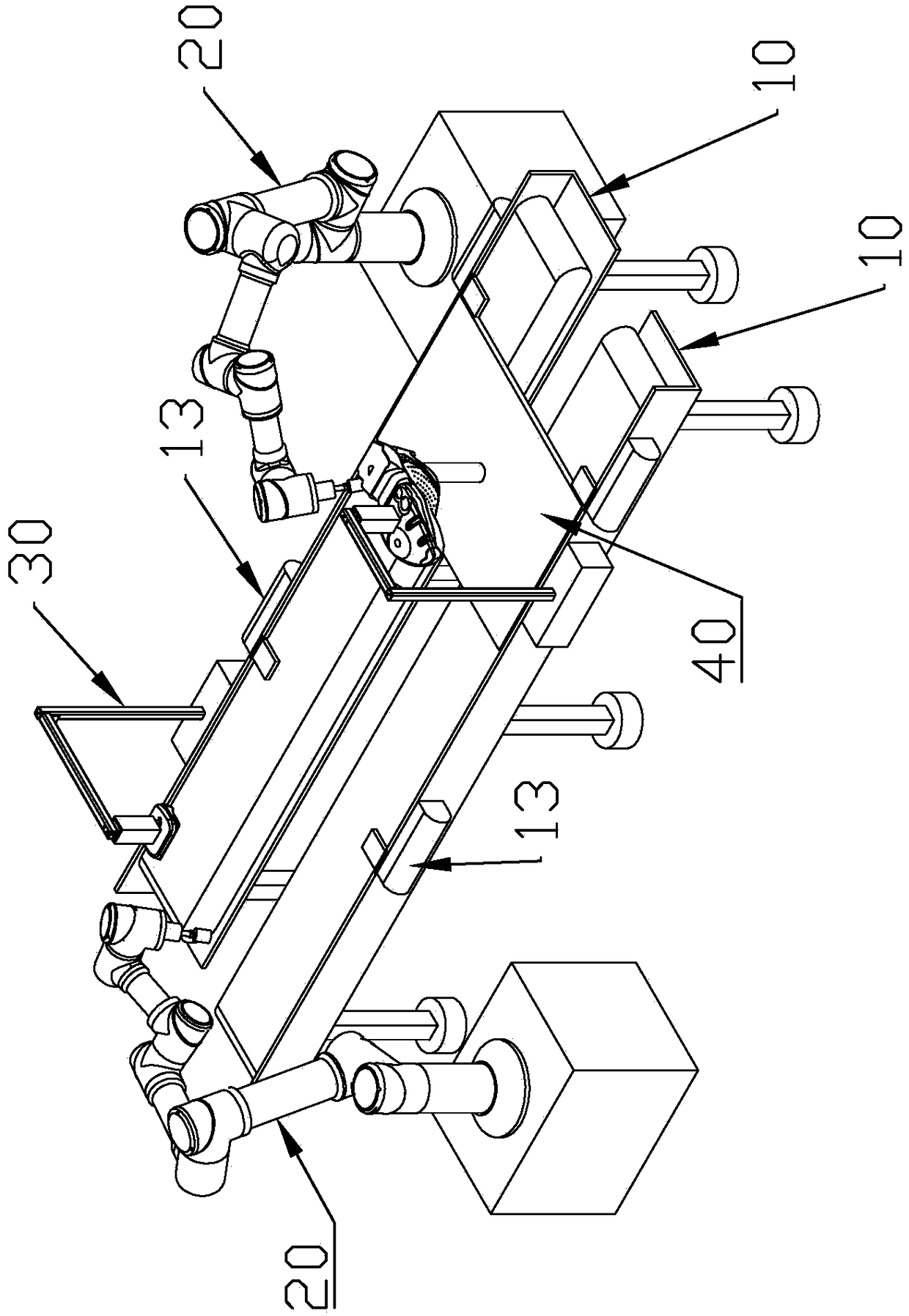

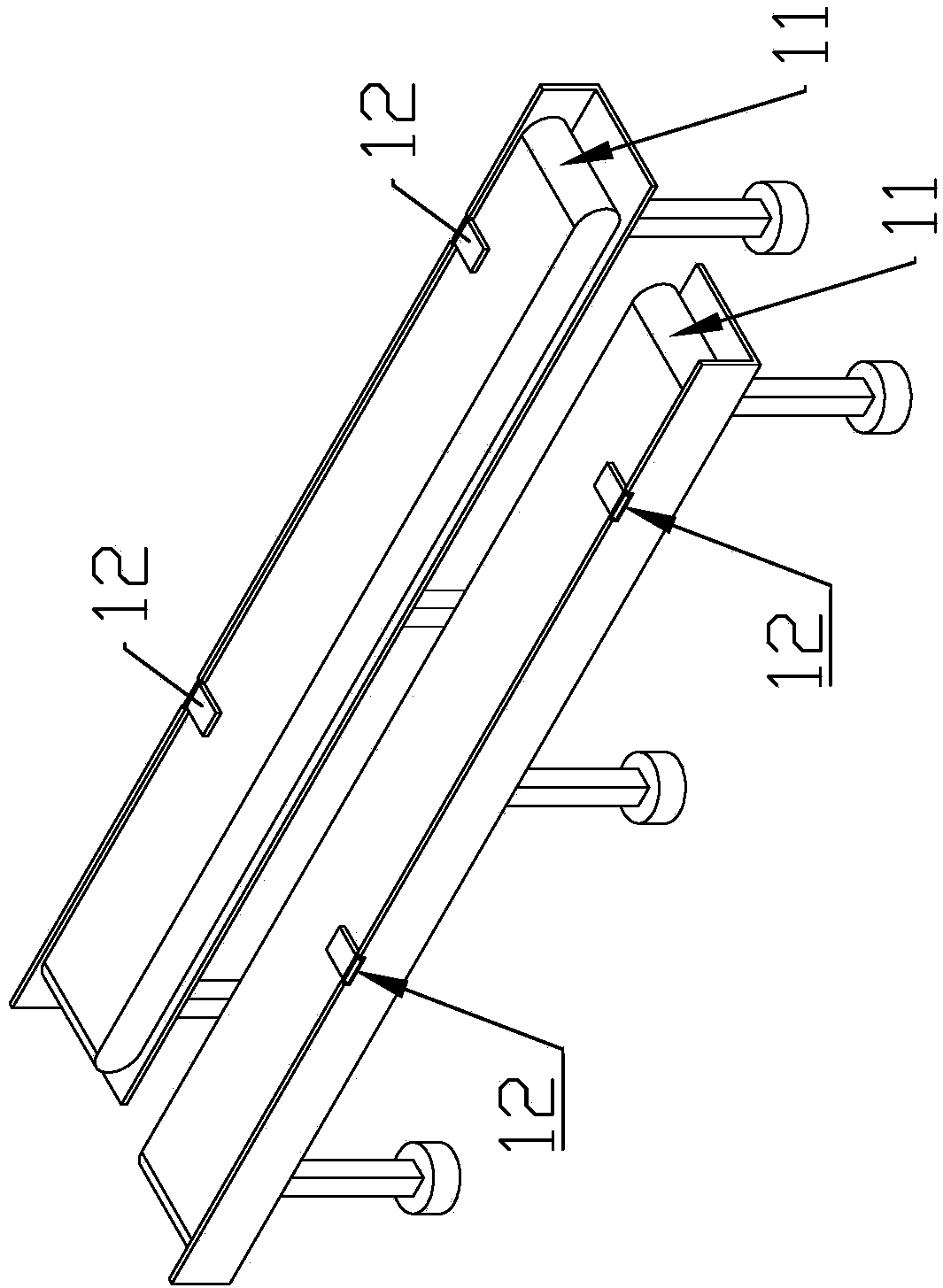

[0022] Combine below Figure 1 to Figure 6 The present invention is further described.

[0023] An automatic shoe sole grinding machine, including a control system, a frame, and a transmission device installed on the frame. A robot arm 20 is arranged. In this embodiment, the two robotic arms 20 are six-joint robotic arms, and each robotic arm 20 includes a grinder 21 installed at the end. An installation platform 40 is placed on the conveying device, and a lifting top support 41 is arranged on the installation platform 40. The top of the lifting top support 41 is arranged with a sole facing upwards. The invention is used for grinding the bottom of the shoe to be processed, so that the bottom of the shoe and the outsole can be closely fitted without gaps. Put the shoe cover to be processed on the foot mold, and a lifting motor that can drive the lifting top support 41 is arranged in the mounting table 40 .

[0024] Two groups of positioning devices are arranged on the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com