Grinding wheel spindle variable-angle automatic control system of fully-automatic digital control roll grinding machine

An automatic control system, roll grinding machine technology, applied in the direction of grinding automatic control devices, grinding machines, grinding machine parts, etc., can solve the problem of large errors that affect the grinding accuracy of the roll surface, grinding quality and grinding efficiency, and roll grinding Surface grinding curve error and other problems, to achieve the effect of reducing curve grinding error, improving the accuracy and quality of curve grinding, and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

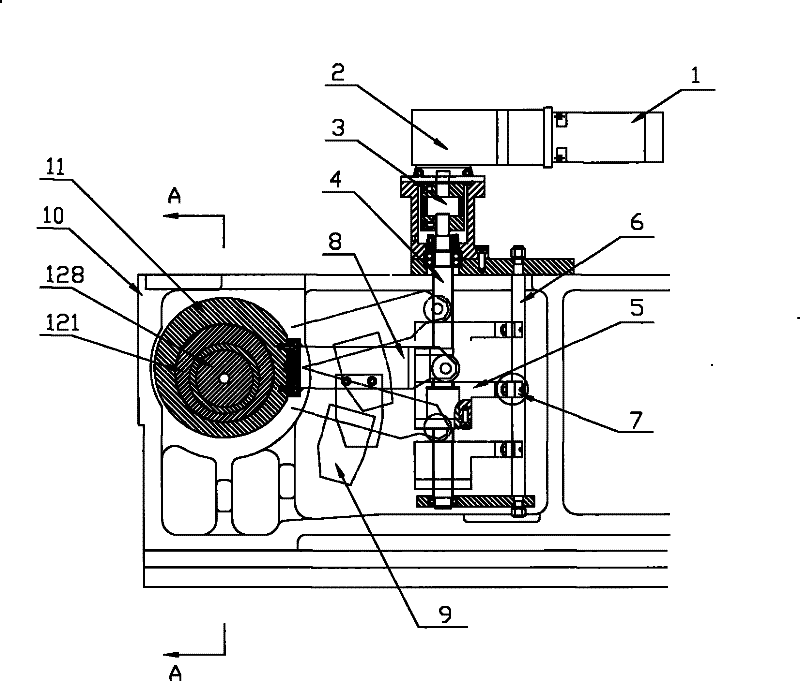

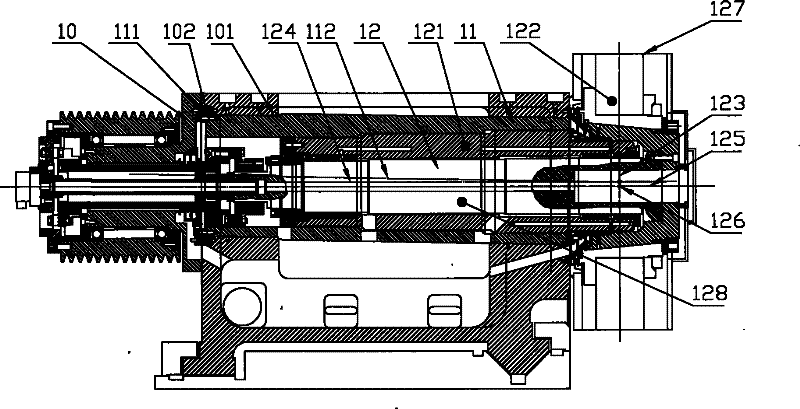

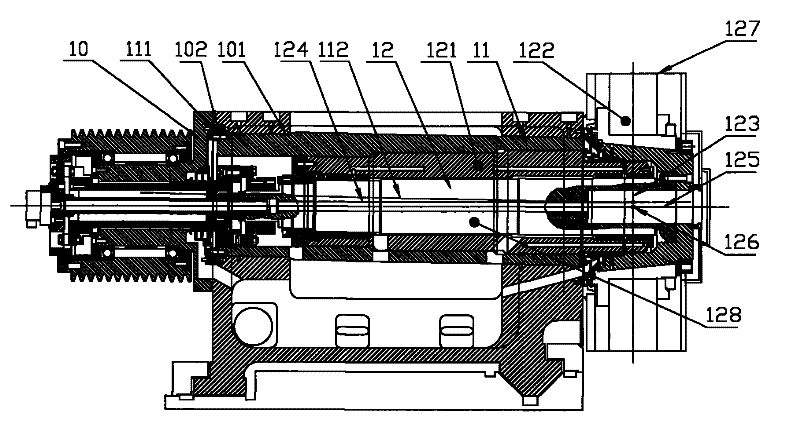

[0010] Embodiment: A fully automatic CNC roll grinder grinding wheel spindle variable angle automatic control system, including a full digital AC servo motor 1, a reducer 2, a coupling 3, a ball screw pair 4, a nut sleeve 5, a guide rod 6, Positioning slider 7, swing rod 8, counterweight 9, grinding frame 10 and dynamic and static pressure grinding head 12, the power output of the full digital AC servo motor 1 is sent to the reducer 2, and the power output end of the reducer 2 is connected to the coupling 3 The power input end, the power output end of the coupling 3 is connected to the power input end of the ball screw pair 4, the ball screw pair 4 and the nut sleeve 5 are freely meshed and connected through threads, and a positioning slider 7 is slidably fixed on the guide rod 6, The nut sleeve 5 is fixedly connected with the positioning slider 7, one end of the swing rod 8 is placed on the nut sleeve 5, and the side of the swing rod 8 near the nut sleeve 5 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com