Quartz stone chamfering machine

A technology of chamfering machine and quartz stone, which is used in conveyors, parts of grinding machine tools, machine tools suitable for grinding workpiece edges, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

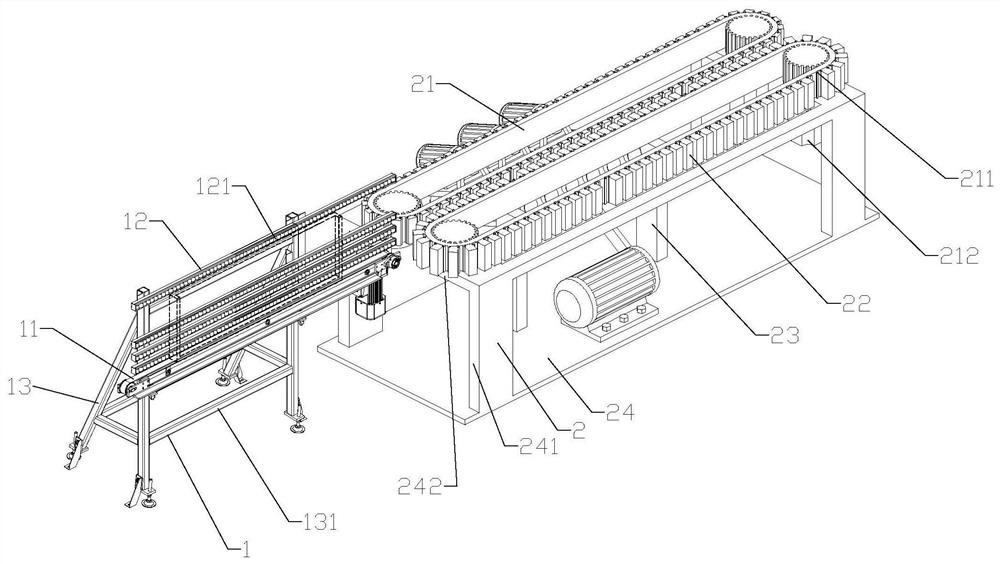

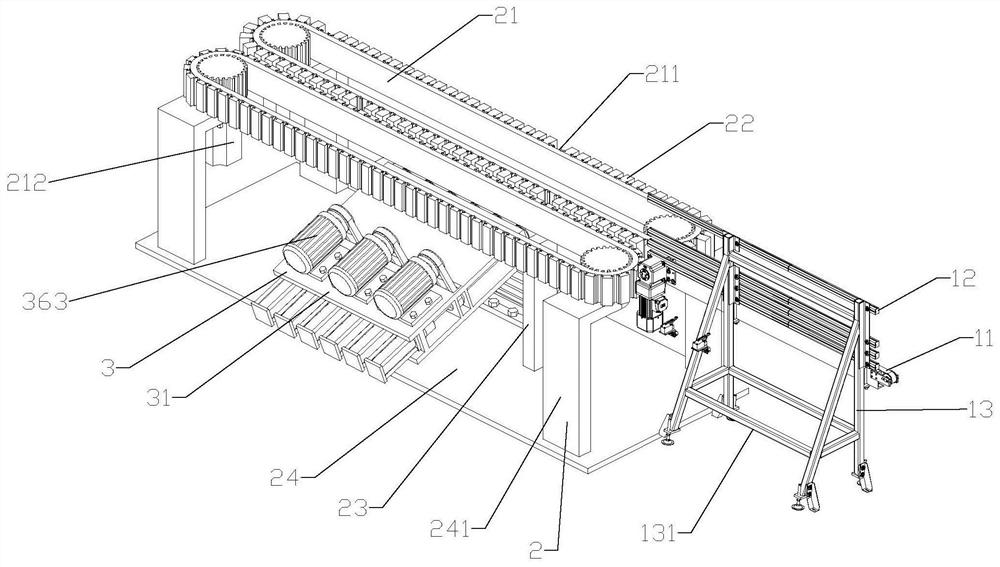

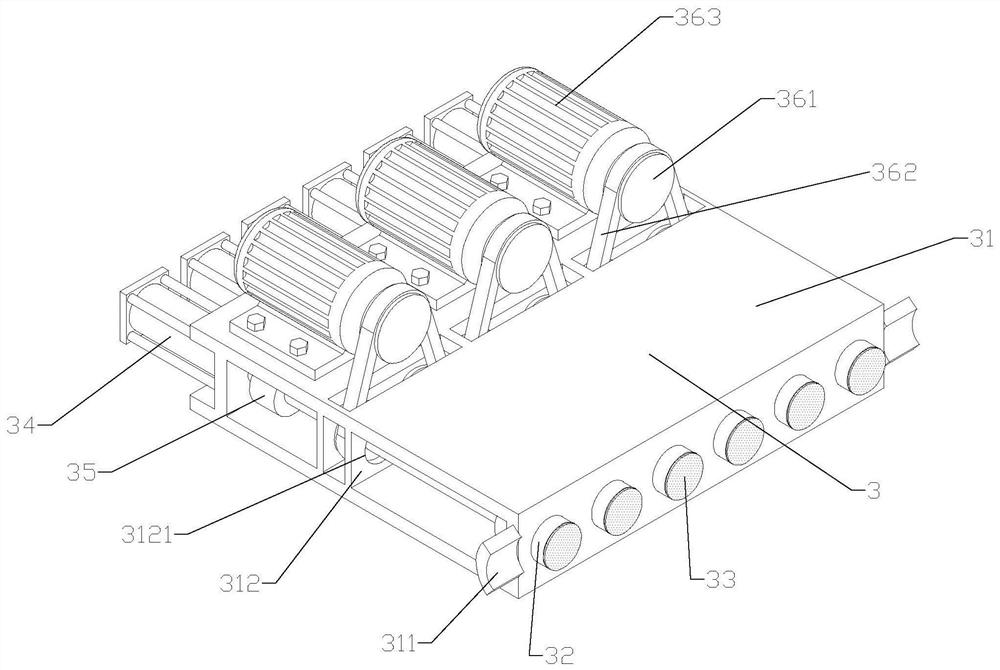

[0028] as attached figure 1 To attach Figure 9 The quartz stone chamfering machine shown, it includes feeding frame 1 and conveying frame 2, as attached figure 1 As shown, the feeding rack 1 includes two tripods 13 , and the two tripods 13 are fixedly connected by a plurality of cross bars 131 . The timing belt 11 is horizontally arranged on the feeding rack 1, and the timing belt 11 is arranged on one side of the feeding rack 1. During specific implementation, a fixed plate 111 is respectively fixed on the left and right sides of the synchronous belt 11, and the fixed plate 111 passes through the It is fixed on the tripod 13 and the cross bar 131 by welding or bolting. A plurality of rows of centralizing rods 12 are arranged horizontally on one side above the synchronous belt 11 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com