Work-piece contouring device

A technology for workpieces and clamping parts, which is applied to spherical grinders, grinders, manufacturing tools, etc., to achieve the effects of improving grinding accuracy, convenient operation and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

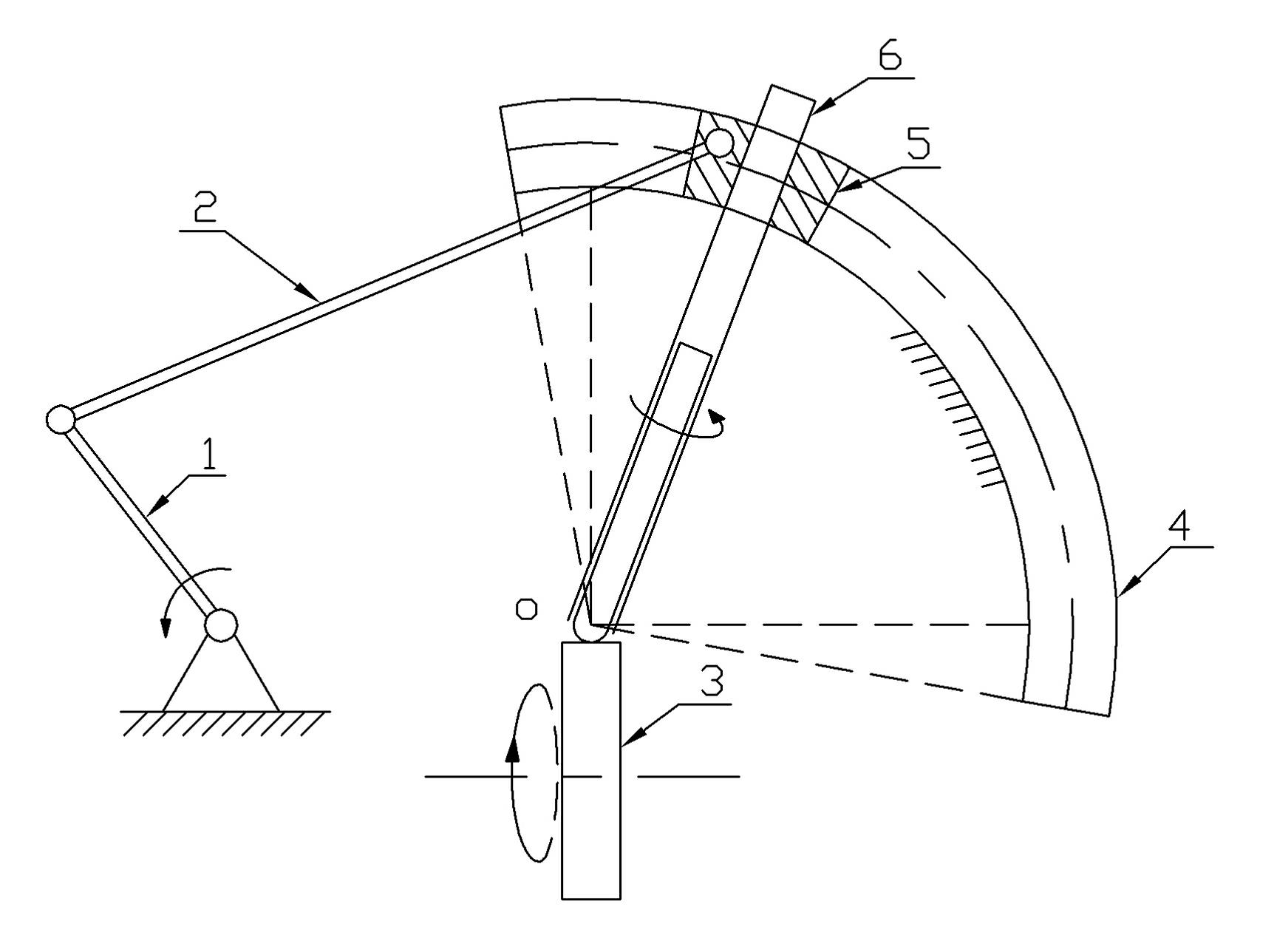

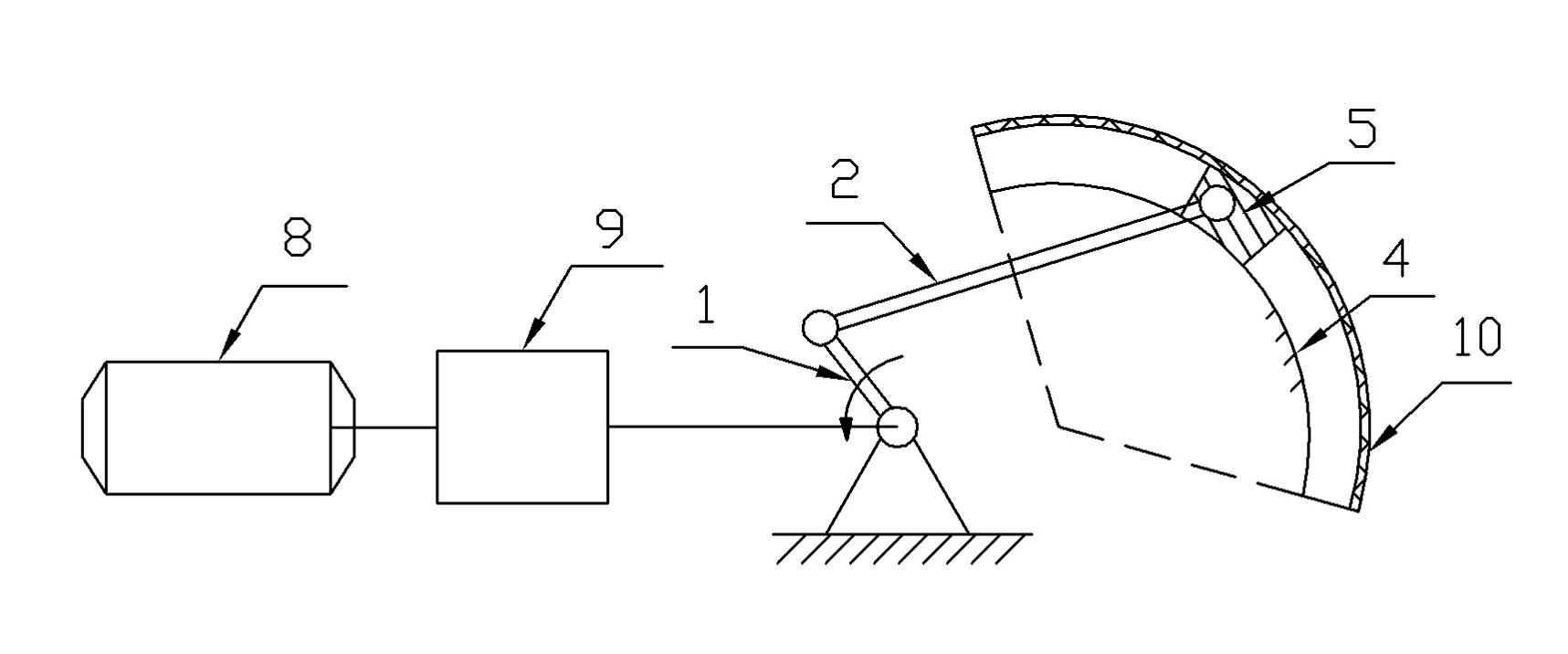

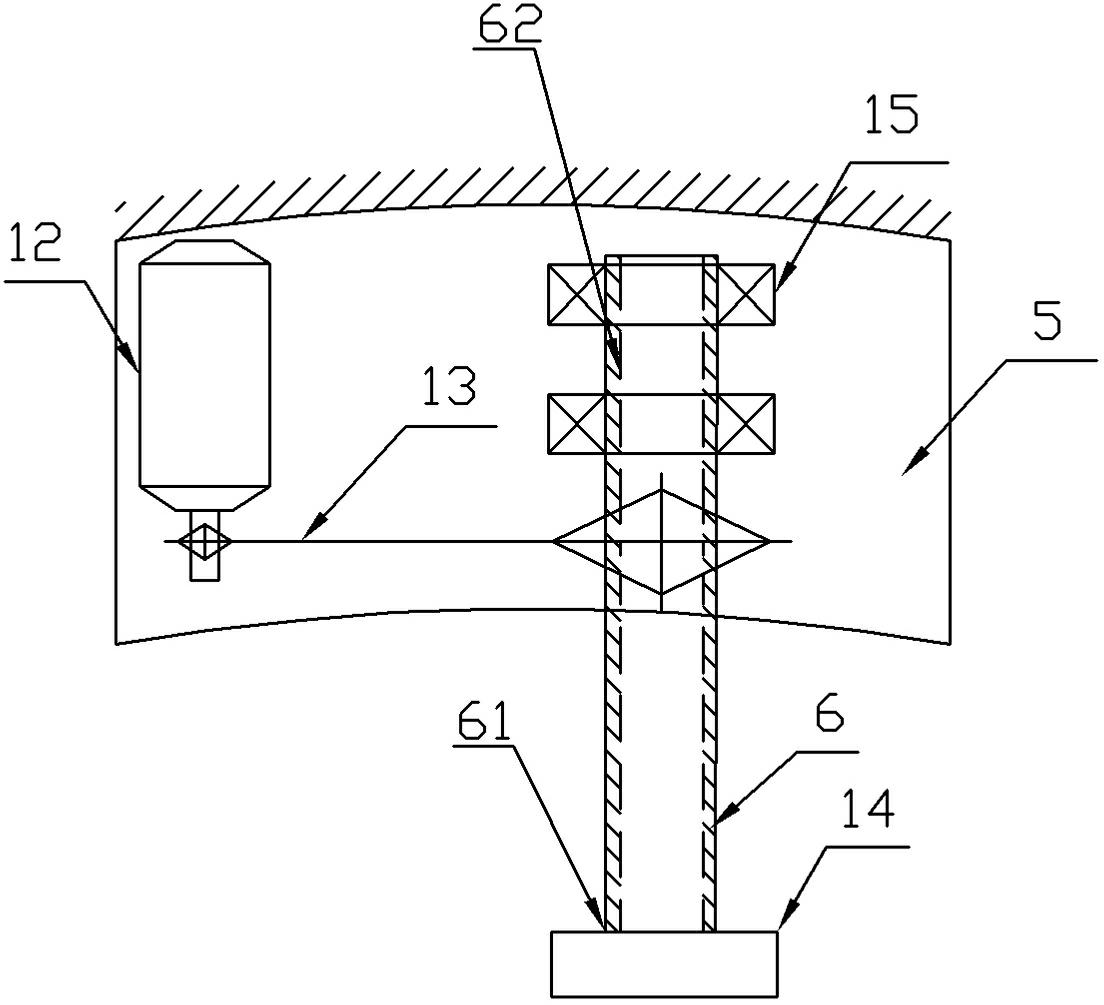

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an embodiment of a workpiece grinding spherical surface device, the workpiece grinding spherical surface device in this embodiment includes a workbench 15, and the workbench 15 is supported with a grinding wheel frame and a clamping part for clamping the workpiece 7. The clamping part includes a clamping shaft 6 for clamping the workpiece. One end of the clamping shaft 6 facing the grinding wheel 3 is a clamping end for fixing the workpiece 7 on the clamping shaft 6. The clamping shaft 6 is driven by a shaft drive mechanism. Rotate around its own rotation center axis, the grinding ball device also includes a rotation mechanism, the rotation mechanism drives the clamping shaft 6 to swing around the rotation center of the rotation mechanism, and a grinding wheel 3 is installed on the grinding wheel frame, and the grinding wheel 3 is located on the Near the center of revolution of the above-mentioned slewing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com