Stainless steel highly-polished surface nondestructive grinding and roll finish repairing method

A repair method, stainless steel technology, applied in grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems of uneven high-gloss surface, large yield loss, product deformation, etc., achieve process saving, good mechanical performance, and reduce manufacturing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

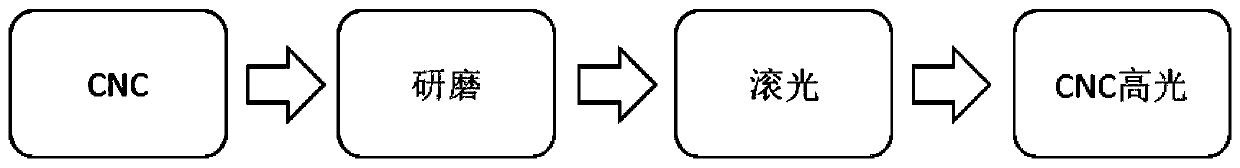

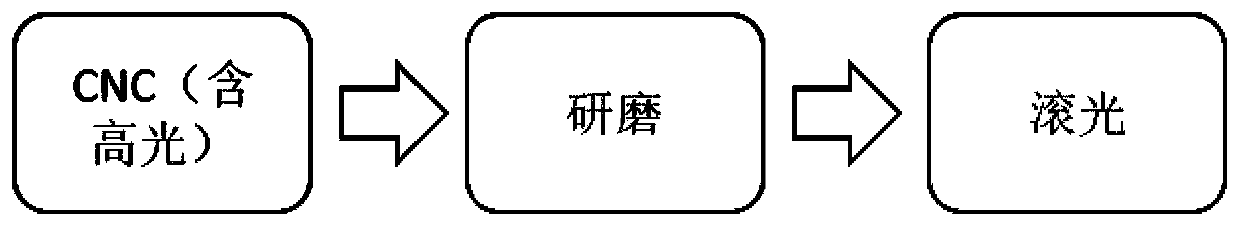

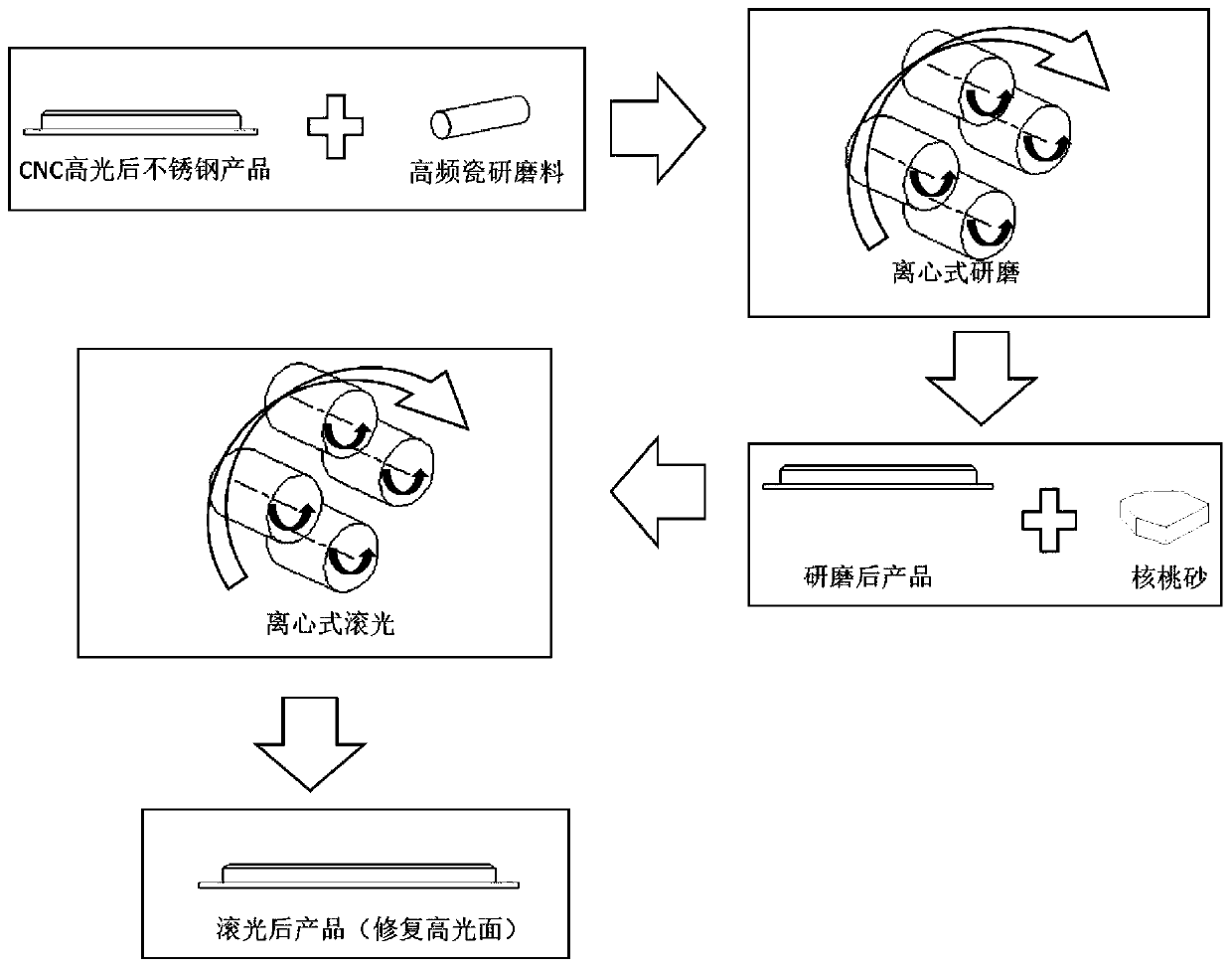

[0044] A. CNC, CNC processing and CNC high-gloss treatment for stainless steel products.

[0045] B. Grinding. Place stainless steel products in the drum of a centrifugal grinder, and use high-frequency porcelain abrasives to perform centrifugal grinding on stainless steel products. The grinding and rotating mode of the drum of the centrifugal grinder includes rotation around the central axis of the drum and centrifugal grinding. The type grinding machine revolves for the shaft, which greatly improves the grinding efficiency and effectively removes the burrs on the product surface. The rotational speed of the drum of the centrifugal mill was 50 Hz. Grinding time is 5min; single production capacity is 100pcs / barrel.

[0046]C, tumbling, the stainless steel product after grinding is placed in the cylinder of centrifugal type tumbling machine, with walnut sand as grinding material, carry out tumbling treatment, the model of walnut sand is 10# sand mold, and tumbling grinding tim...

Embodiment 2

[0048] A. CNC, CNC processing and CNC high-gloss treatment for stainless steel products.

[0049] B. Grinding. Place stainless steel products in the drum of a centrifugal grinder, and use high-frequency porcelain abrasives to perform centrifugal grinding on stainless steel products. The grinding and rotating mode of the drum of the centrifugal grinder includes rotation around the central axis of the drum and centrifugal grinding. The type grinding machine revolves for the shaft, which greatly improves the grinding efficiency and effectively removes the burrs on the product surface. The rotational speed of the drum of the centrifugal mill was 50 Hz. Grinding time is 10min; single production capacity is 100pcs / barrel.

[0050] C, tumbling, the stainless steel product after grinding is placed in the cylinder of centrifugal type tumbling machine, with walnut sand as grinding material, carry out tumbling treatment, the model of walnut sand is 10# sand mold, and tumbling grinding t...

Embodiment 3

[0052] A. CNC, CNC processing and CNC high-gloss treatment for stainless steel products.

[0053] B. Grinding. Place stainless steel products in the drum of a centrifugal grinder, and use high-frequency porcelain abrasives to perform centrifugal grinding on stainless steel products. The grinding and rotating mode of the drum of the centrifugal grinder includes rotation around the central axis of the drum and centrifugal grinding. The type grinding machine revolves for the shaft, which greatly improves the grinding efficiency and effectively removes the burrs on the product surface. The rotational speed of the drum of the centrifugal mill was 50 Hz. Grinding time is 8 minutes; single production capacity is 100pcs / barrel.

[0054] C, tumbling, place the ground stainless steel product in the drum of a centrifugal tumbling machine, and use walnut sand as the grinding material to carry out tumbling treatment. The model of the walnut sand is 10# sand mold, and the tumbling grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com