Casting head for compact casting

A technology of compacting grouting and grouting head, which is applied in the field of grouting nozzle and grouting head for compacting grouting, which can solve the problem of excessive waste of grouting, the inability to control the direction of grouting, and the inability to realize regional grouting. problems such as slurry, to achieve the effect of saving slurry, controlling the problem of slurry running, and good grouting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

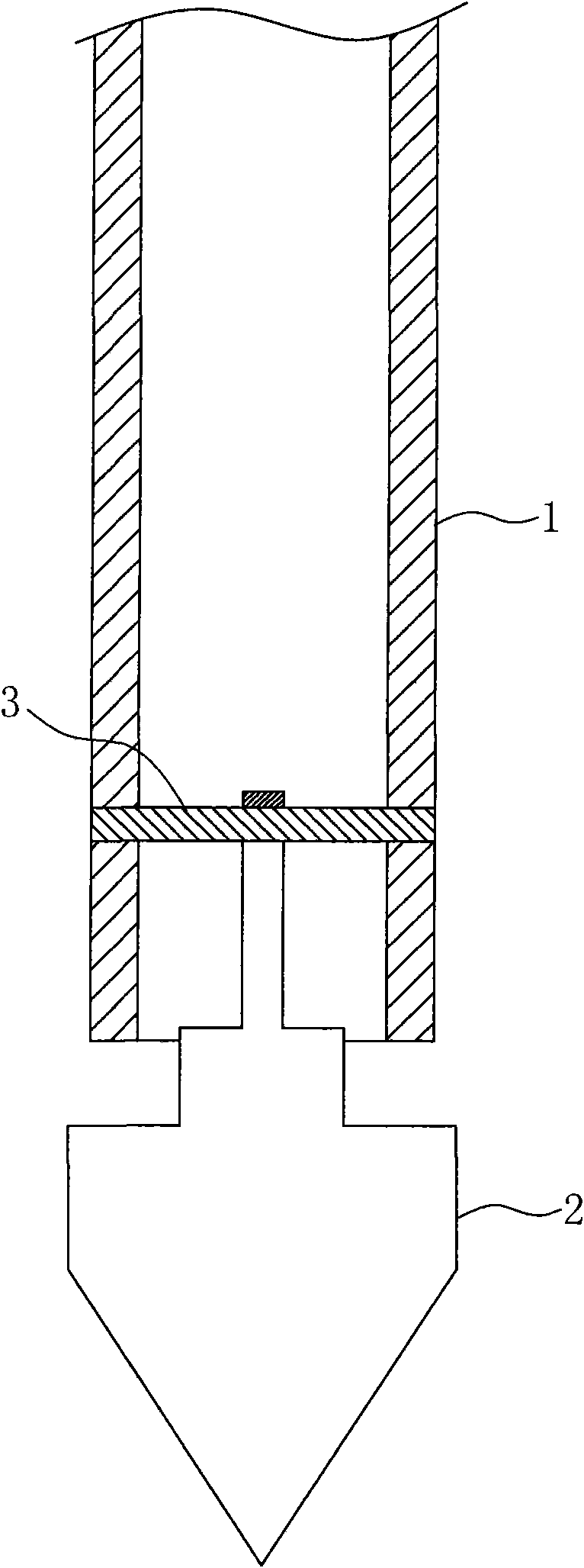

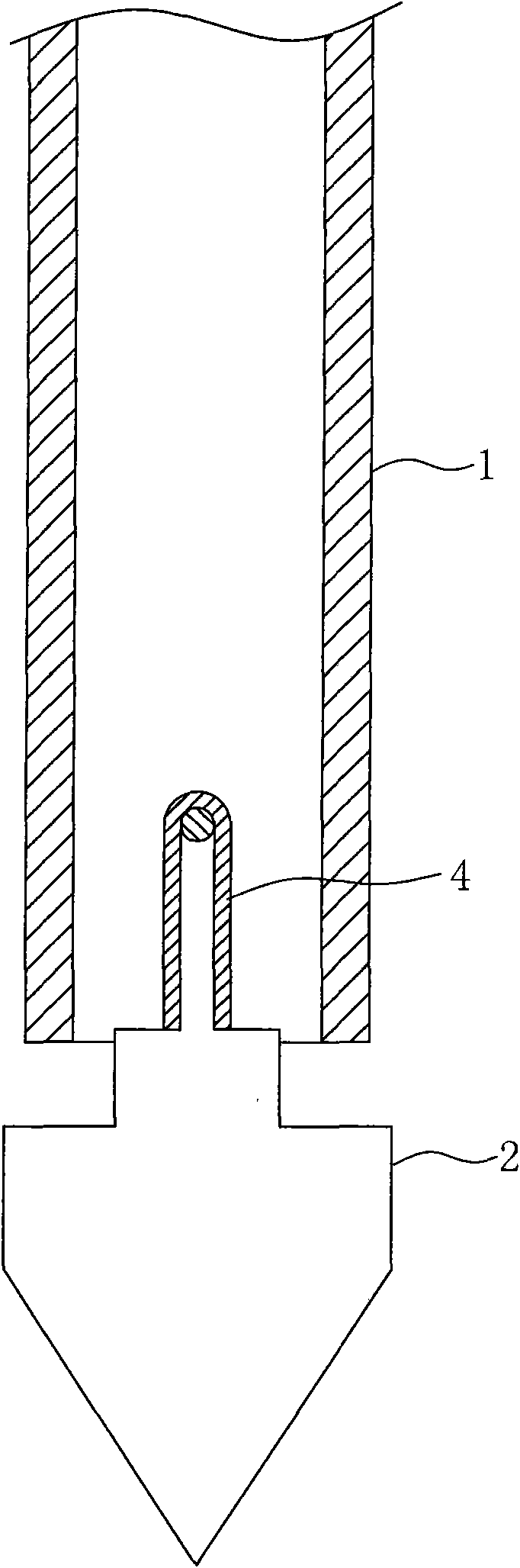

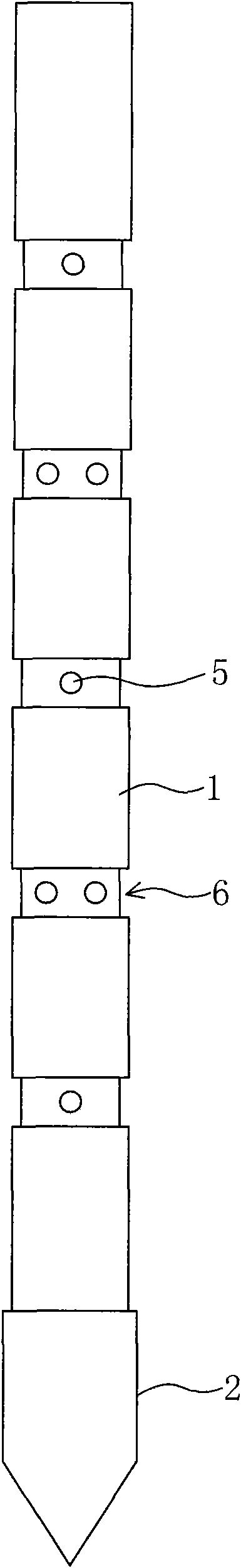

[0028] See attached Figure 3-5 As shown, a grouting head for compaction grouting includes a hollow drill rod 1 and a drill bit 2 arranged at one end of the drill rod, and one side of the drill rod 1 is provided with 7 injection holes 5, the The injection holes 5 are arranged at intervals from near to far relative to the drill bit, and are divided into 5 groups, each group includes 1 to 2 injection holes, and an annular groove 6 is arranged on the outer wall of the drill pipe corresponding to each group of injection holes. The width of the groove is larger than the diameter of the injection hole, and the depth is 1 to 2 millimeters, and the outlet of each injection hole is located in the groove. The injection holes are located on one side of the drill pipe, so grouting can be performed in a limited area to form an anti-seepage curtain, which reduces the leakage of slurry, thereby effectively controlling the problem of slurry running; the upper and lower distances of each injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com