A Long Arm Longitudinal Strip Type Paste Filling Recovery Technology

A technology of paste filling and longitudinal striping, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of easy occurrence of pulp running, poor filling effect, etc., prevent spontaneous combustion and water accumulation, use less equipment, and comprehensive The effect of simple mining equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

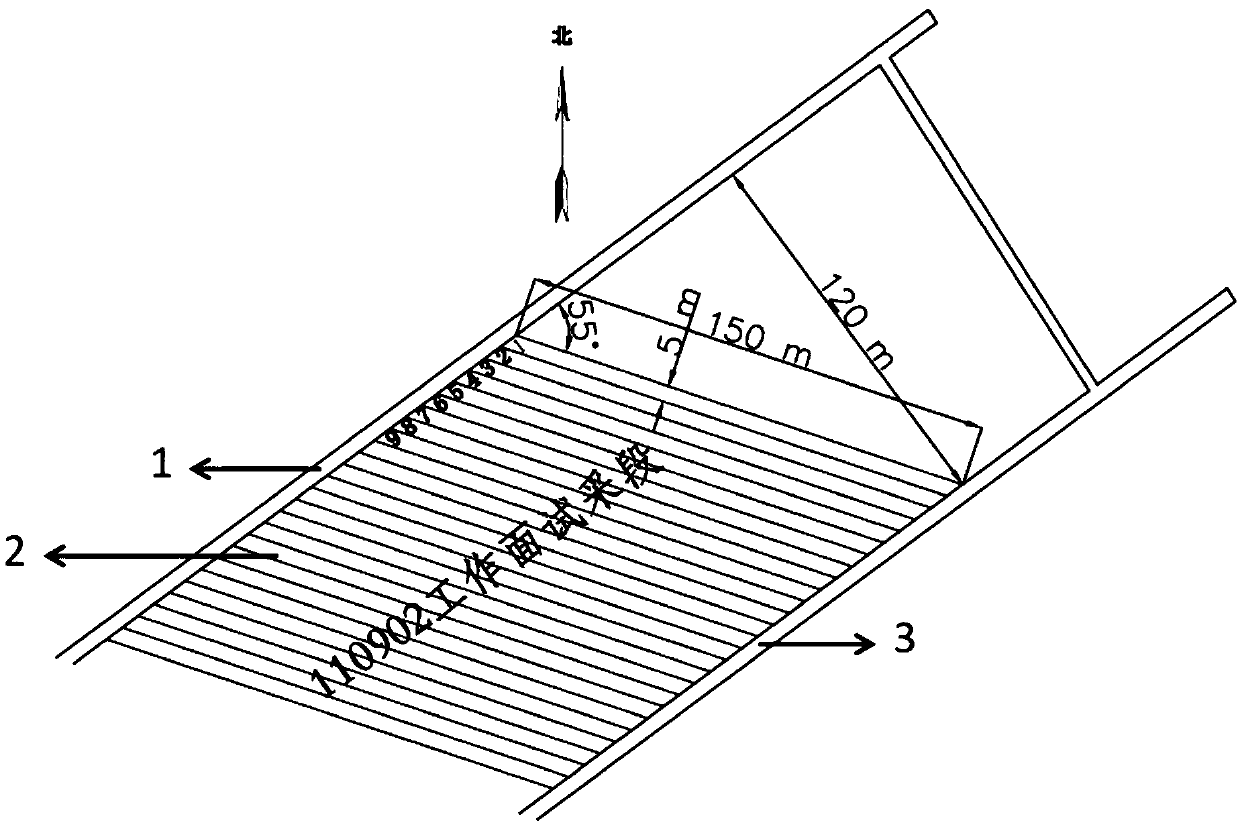

[0041] Taking the 110902 working face designed by Wuhai Tianyu Industry and Trade Co., Ltd. as the construction site, the average thickness of the coal seam of the 110902 working face is 5.2m, and the strike length is 300m.

[0042] Set mining branch roadway 2, which is arranged at an angle of 55° with transportation channel 1. The opening of the branch roadway is located in transportation channel 1, and each branch roadway is arranged in parallel. They are numbered 1, 2, 3, 4... from the inside to the outside; The length of each branch roadway is 150m, the width is 5m, and the height of the branch roadway is the same as the average thickness of the coal seam, which is 5.2m.

[0043]The opening point of the branch roadway in the working face is located in the transport channel 1 of the working face, and is constructed along the roof of the coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com