Flat oxygen sensor and preparation method thereof

An oxygen sensor and flat-plate technology, which is applied in the field of flat-type oxygen sensor and its preparation, can solve the problems of low bending strength chip assembly yield, blockage of reference air channels, and high mass production costs, so as to prevent interlayer cracking, The effect of accelerating drying speed and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing a flat oxygen sensor, comprising the steps of:

[0040] (1) Preparation of ceramic green sheets:

[0041] Select a specific surface area of 5-8m 2 / g, doped with 5%molY 2 o 3 Based on the quality of zirconia, add 16-22% organic solvent; 1-3% dispersant; 3-8% plasticizer; 3-10% binder ball milling and mixing 24 - After 30 hours, a uniform and stable casting slurry is obtained, and the casting slurry is prepared into a ceramic green sheet with a thickness of 0.2-0.25mm;

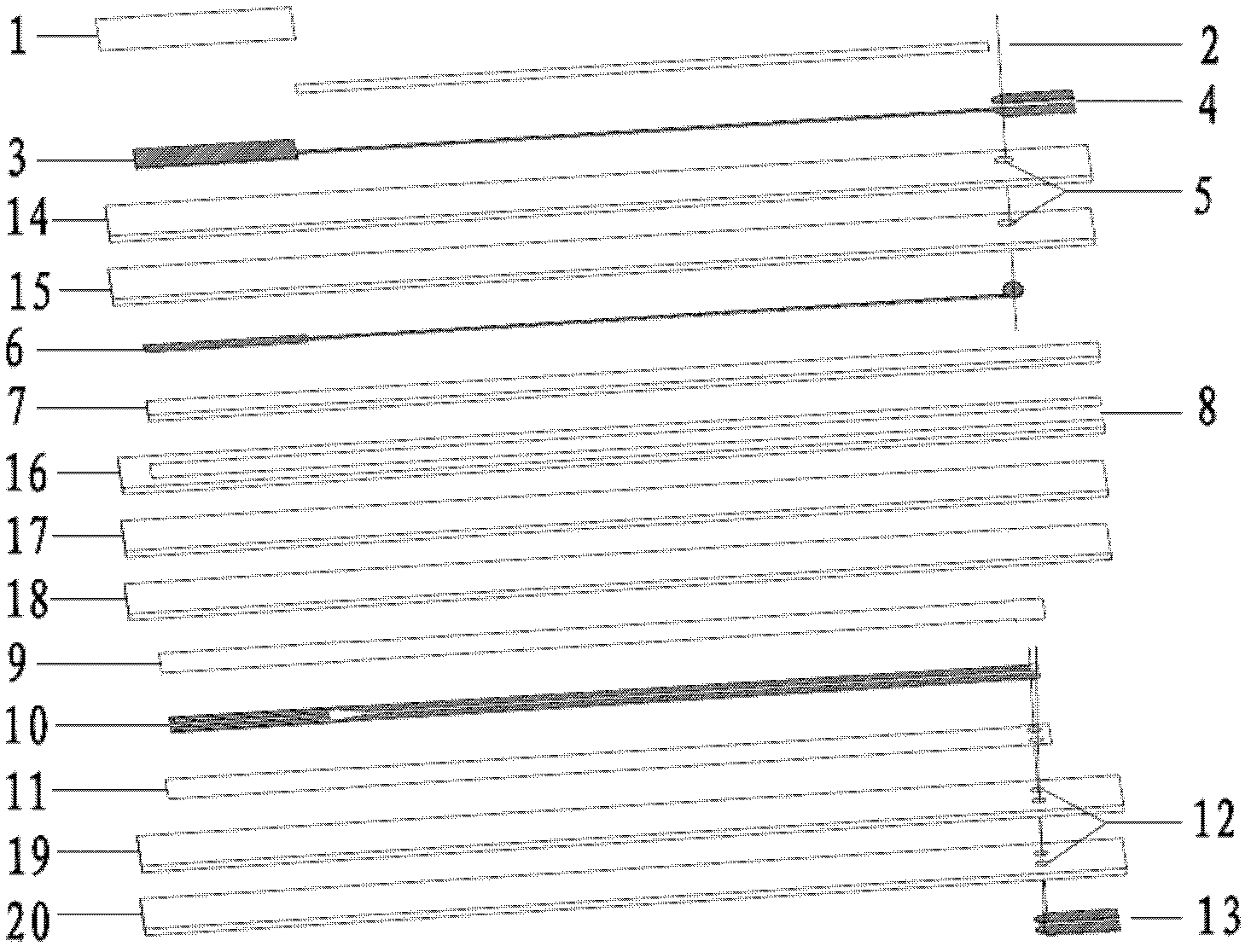

[0042] (2) Shaping of ceramic green sheets:

[0043] Punch a group of 2-4 circular holes with a diameter of 0.1-0.2mm on the first layer of ceramic green sheet 14 and the second layer of ceramic green sheet 15; the sixth layer of ceramic green sheet 19 and the seventh layer of ceramic green sheet 20 Two sets of 2-4 small circular holes with a diameter of 0.1-0.2 mm are punched up; a long groove with an open tail is laser cut in the middle of the third layer of ceramic green ...

Embodiment 1

[0051] Step 1: Preparation of Ceramic Green Sheets

[0052] A mixed solution of 80ml of ethanol and 80ml of toluene was used as an organic solvent; 15g of fish oil was added into a ball mill tank as a dispersant, and the three were stirred evenly with a polytetrafluoroethylene rod; 1Kg was weighed with a specific surface area of 5m 2 / g, doped with 5%molY 2 o 3 The superfine zirconia powder was added into the ball mill jar and milled for 10 hours; then 50g of polyethylene glycol was used as plasticizer; the mixture of 25g polyvinyl alcohol and 25g ethyl cellulose was added into the ball mill jar and ball milled for 14 hours . The mixed slurry was defoamed and cast into a ceramic green sheet with a thickness of 0.25 mm.

[0053] Step 2: Shape the ceramic green sheet

[0054] Punch a group of 4 small circular holes with a diameter of 0.2 mm on the first layer of ceramic green sheets and the second layer of ceramic green sheets. Two groups of 4 small circular holes with a ...

Embodiment 2

[0062] Step 1: Preparation of Ceramic Green Sheets

[0063] A mixed solution of 100ml ethanol and 100ml xylene was used as an organic solvent; 20g fish oil was added into a ball mill tank as a dispersant, and the three were stirred evenly with a polytetrafluoroethylene rod; 1Kg was weighed with a specific surface area of 6m 2 / g, doped with 5%molY 2 o 3 The ultra-fine zirconia powder was added into a ball mill jar and milled for 10 hours; then 60g of butyl phthalate was used as a plasticizer; 80g of polyvinyl butyral was added into a ball mill jar as a binder and ball milled for 16 hours. Degassing and casting the mixed slurry into a ceramic green sheet with a thickness of 0.25 mm;

[0064] Step 2: Shape the ceramic green sheet

[0065] Punch a group of 3 small circular holes with a diameter of 0.15 mm on the first layer of ceramic green sheets and the second layer of ceramic green sheets, and the 3 small holes are arranged symmetrically in a triangle and located in a cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com