Solar cell screen printing plate having paste amount limiting function

A technology of solar cells and current limiting, which is applied in the direction of circuits, electrical components, screen printing machines, etc., can solve the problem of difficulty in controlling the amount of slurry added, and achieve the effects of saving usage, saving slurry, and preventing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

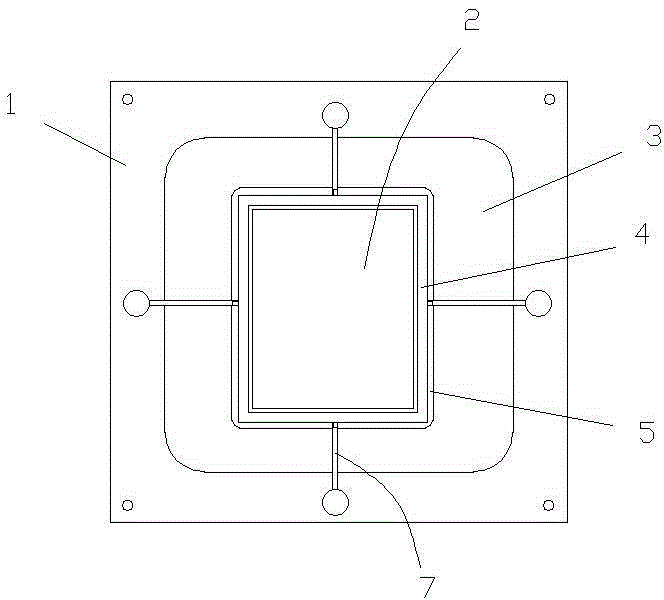

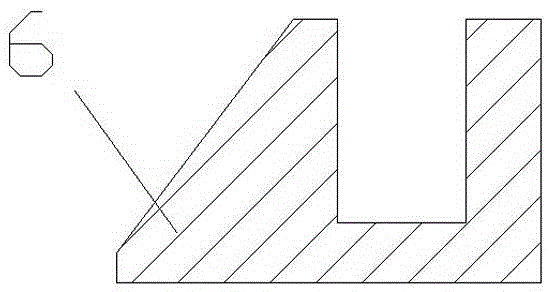

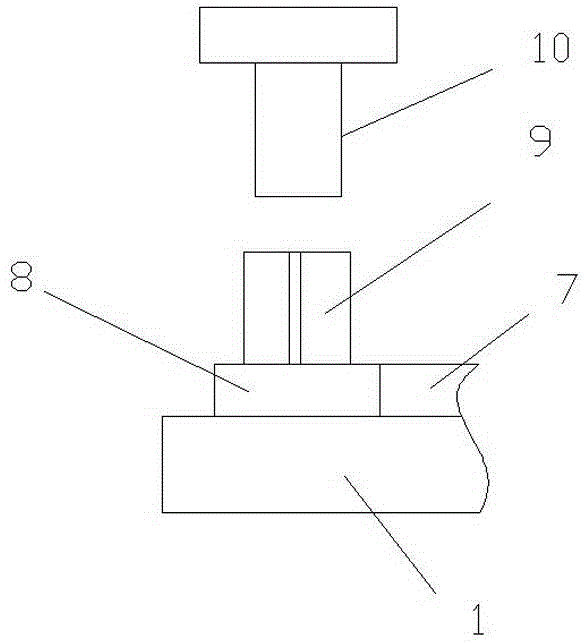

[0021] Such as figure 1 In the shown embodiment, a solar battery sheet screen plate with slurry current limitation includes an outer frame 1 and a screen arranged on the outer frame. The screen is provided with a printing surface in contact with the substrate and a squeegee surface in contact with the squeegee. The printing surface and the squeegee surface are connected by screen holes. The area where the screen holes gather forms a pattern area 2, and the periphery of the pattern area forms a non-pattern area. 3. The four sides of the pattern area 2 on the scraping surface are provided with a current limiting frame 4, and the current limiting frame 4 is an aluminum alloy frame. The current-limiting frame 4 is square, and the thickness of the aluminum alloy used is 3 mm. The dimensions of the current-limiting frame are: length 250 mm, width 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com