Control system for slurry supplying of modular-structure quick-reaction slurry tank

A fast-response, modular structure technology, applied in the control/regulation system, liquid level control, non-electric variable control, etc., can solve the problems of slurry waste and production efficiency reduction, so as to ensure the quality of sizing, improve production efficiency and save energy. The effect of slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

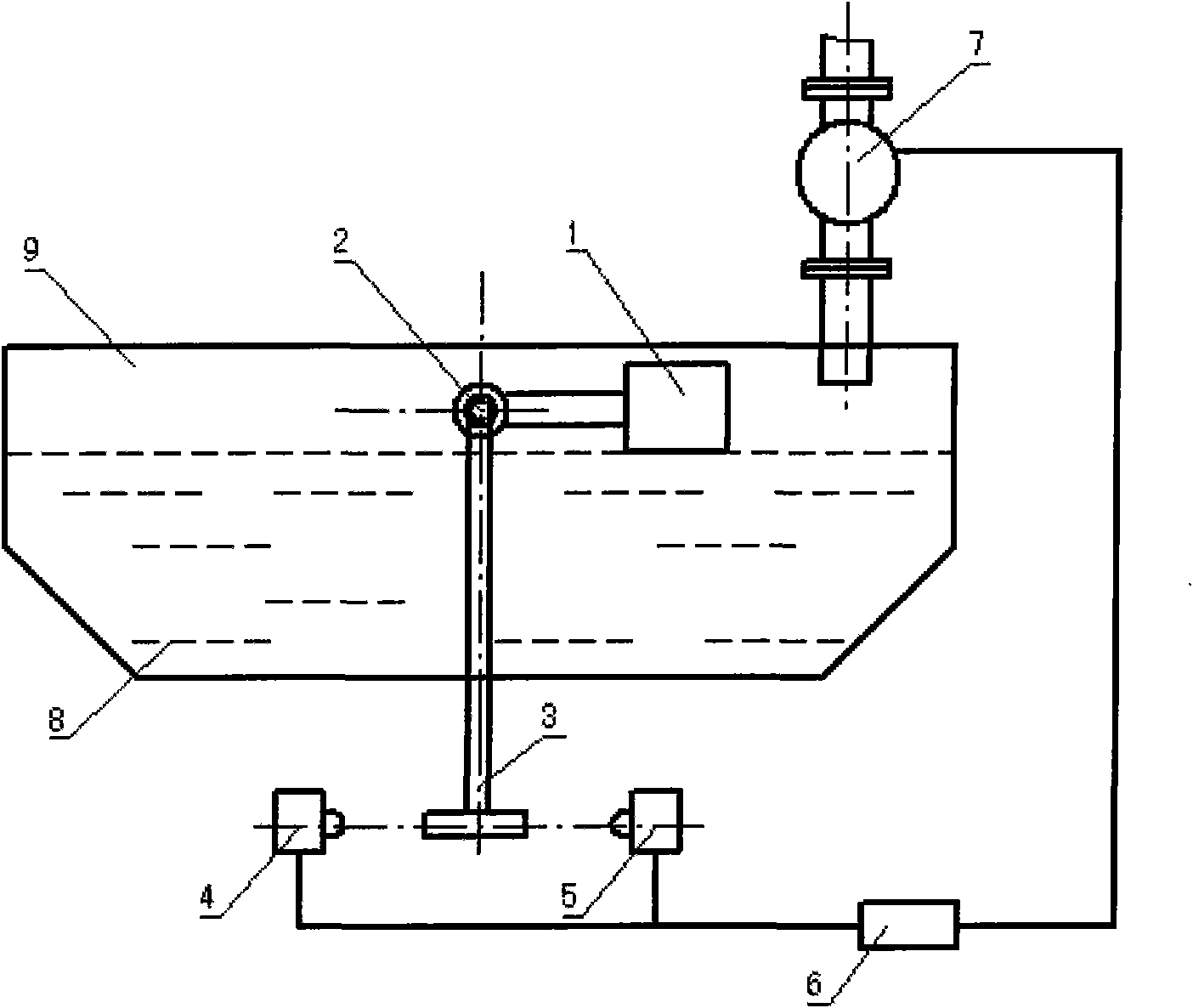

[0009] Such as figure 1 As shown, the modular structure of the slurry control system of the slurry combined machine includes a floating ball 1, a rotating shaft 2, a rotating rod 3, a travel switch 4, a solenoid valve 6, and a cylinder ball valve 7. The floating ball 1 and the rotating rod 3 are installed on the rotating shaft 2 Above, the rotating shaft 2 is fixed on the side plate of the slurry tank 9, the travel switches 4, 5 are connected with the solenoid valve 6, and the solenoid valve 6 is connected with the pneumatic ball valve 7.

[0010] The travel switches 4, 5 are connected with the electromagnetic valve 6 through communication cables.

[0011] The working principle of the present invention is: when the slurry 8 in the slurry tank 9 is higher or lower than the normally set liquid level, the floating ball 1 will float up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com