Processing method for hollowed-out jacquard corduroy

A processing method and hollow jacquard technology, which is applied in the processing of textile materials, textiles, dry cleaning fiber products, etc., can solve the problem of large investment in equipment, and achieve the effect of reducing production and processing costs, good antistatic effect, and improving air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: prepare 16 hollow jacquard corduroys

[0034] 1.1 Use a rapier loom to alternately feed pure cotton yarn and water-soluble yarn in a ratio of 10:2 to weave gray cloth.

[0035] 1.2 Pass the obtained gray cloth through the MH012-20 gas singeing machine quickly, using 4 burners, two positive and two reverse, the flame temperature is 1100°C, and the speed is 105m / min.

[0036] 1.3 The gray cloth after singeing is subjected to cold stacking and short steaming treatment:

[0037] A. Cold stack

[0038] The first choice is to prepare cold pile working fluid, which is mixed with the following ingredients: refining agent FORYL MAG 12-17g / L, 27.5% hydrogen peroxide 23-25g / L, solid sodium hydroxide 35-45g / L L;

[0039] Next, the gray cloth is soaked and rolled with the above-mentioned cold stack working fluid, and the rolling rate is 80%;

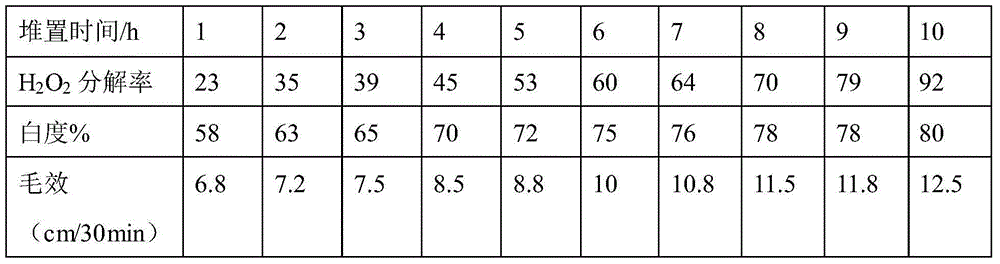

[0040] Afterwards, the gray cloth that has been subjected to steps of dipping and rolling is stacked at a temperature of 48...

Embodiment 2

[0051] Embodiment 2: prepare 21 hollow jacquard corduroys

[0052] 2.1 Use a rapier loom to alternately feed pure cotton yarn or polyester-cotton yarn and water-soluble yarn in a ratio of 104:4 to weave gray cloth.

[0053] 2.2 Pass the obtained gray cloth through the MH012-20 gas singeing machine quickly, using 4 burners, two positive and two reverse, the flame temperature is 1150°C, and the speed is 118m / min.

[0054] 2.3 The gray cloth after singeing is subjected to cold stacking and short steaming treatment:

[0055] A. Cold stack

[0056] The first choice is to prepare cold reactor working fluid, which is mixed with the following ingredients: refining agent FORYL MAG 15g / L, 27.5% hydrogen peroxide 24g / L, solid sodium hydroxide 40g / L;

[0057] Next, the gray cloth is soaked and rolled with the above-mentioned cold stack working fluid, and the rolling rate is 75%;

[0058] Afterwards, the gray cloth that has been subjected to steps of dipping and rolling is stacked at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com