Heat treatment equipment and air cooling unit

A heat treatment equipment, air cooling technology, applied in the field of power electronics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

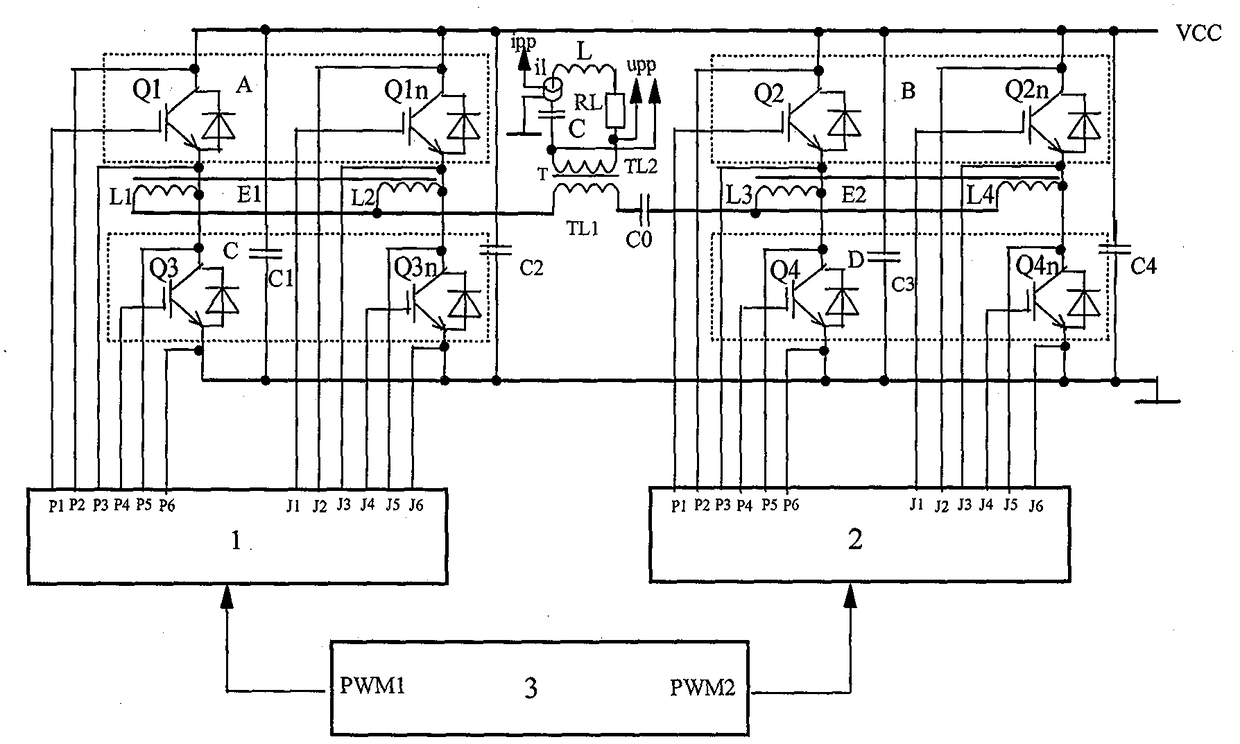

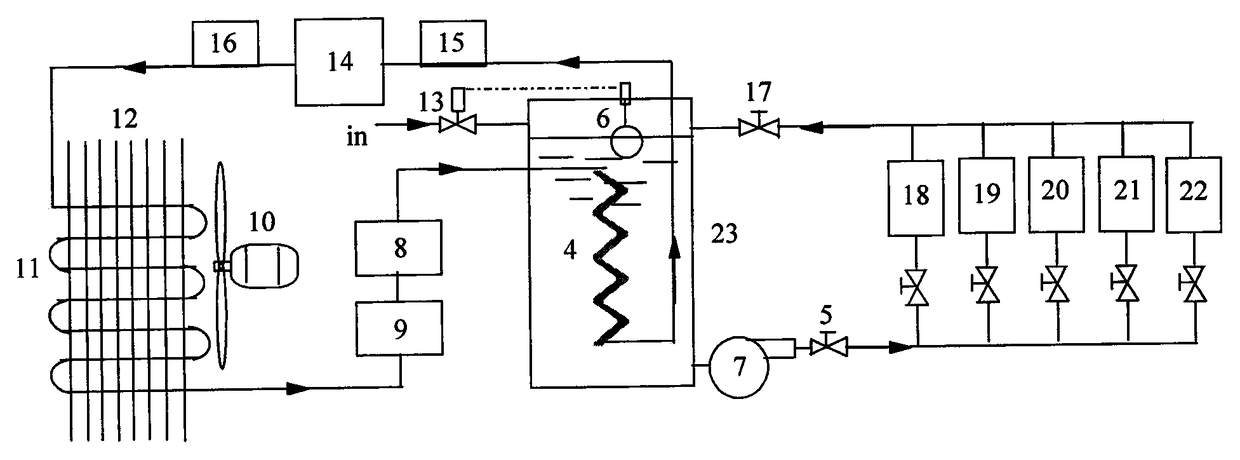

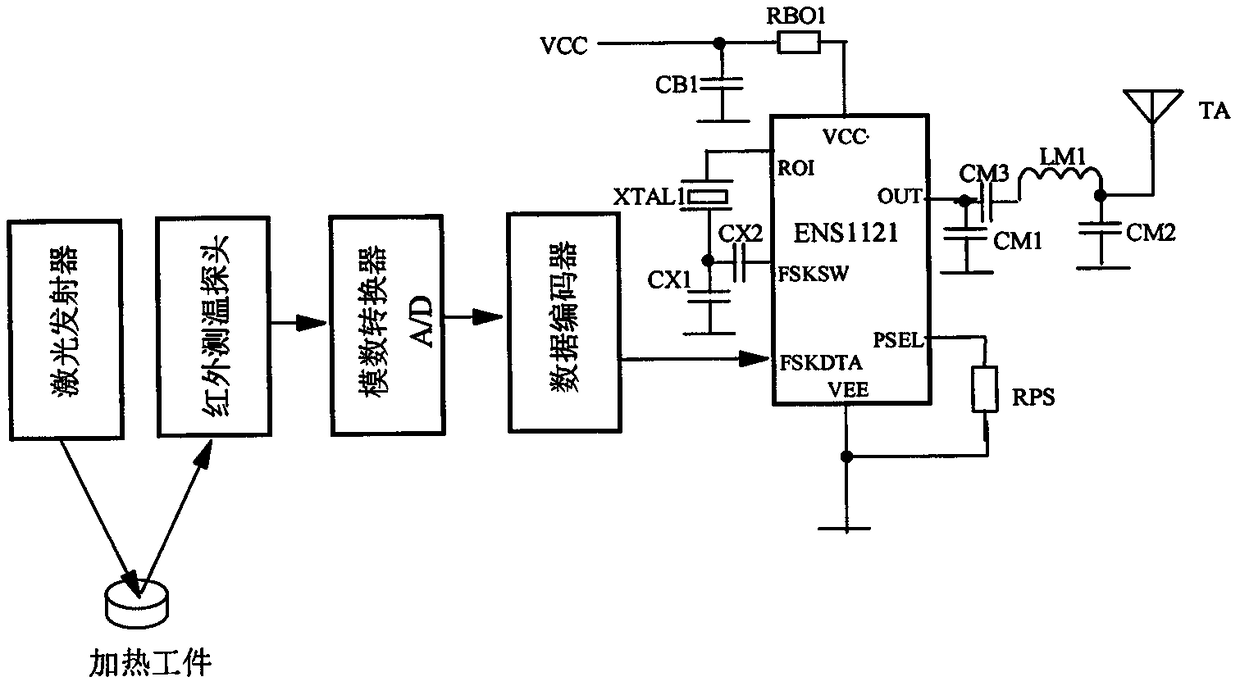

[0015] refer to figure 1 , 2 , 3, 4, the specific embodiment and embodiment of the present invention: comprise three-phase AC power supply, AC contactor, the DSP chip programmable phase control of digital signal processing control board 3TMS320F28335 produces the two-way pulse width modulation of leading and lagging alternate phase shifting PWM 1 , PWM 2 signal, the upper tube and the lower tube set the interlock dead time t DT , are respectively coupled to two dual-channel IGBT drive boards 1 and 2 via optical fibers, and the two half-bridges connected in parallel to form a dual-channel IGBT module are synthesized into an H-bridge inverter. The transformer is matched with a series resonant load circuit, and the four bridge arm IGBTs The module is diagonally turned on and off, zero-power soft start, and the alternate phase-shift switching time is equal. The power consumption is balanced to overcome the defect of large power consumption of the fixed bridge arm. The first dua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com