Oversized-area efficient energy-saving vacuumizing soft foundation treatment system and construction method

A high-efficiency energy-saving and processing system technology, applied in the field of vacuum pumping systems, can solve problems such as inconvenient handling and maintenance, low degree of automation, and large safety hazards, and achieve the effects of saving labor and time, being easy to collect, and reducing the probability of air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

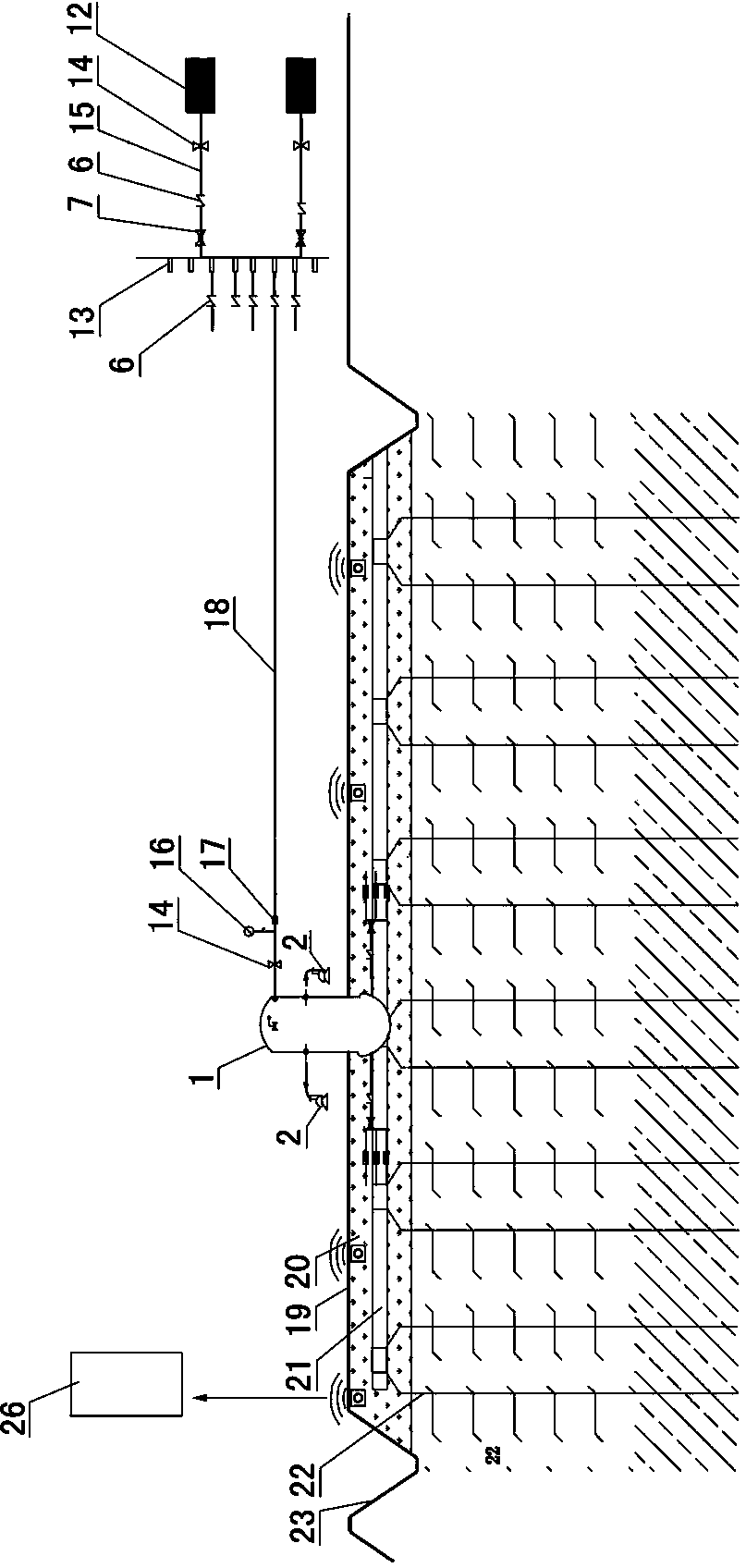

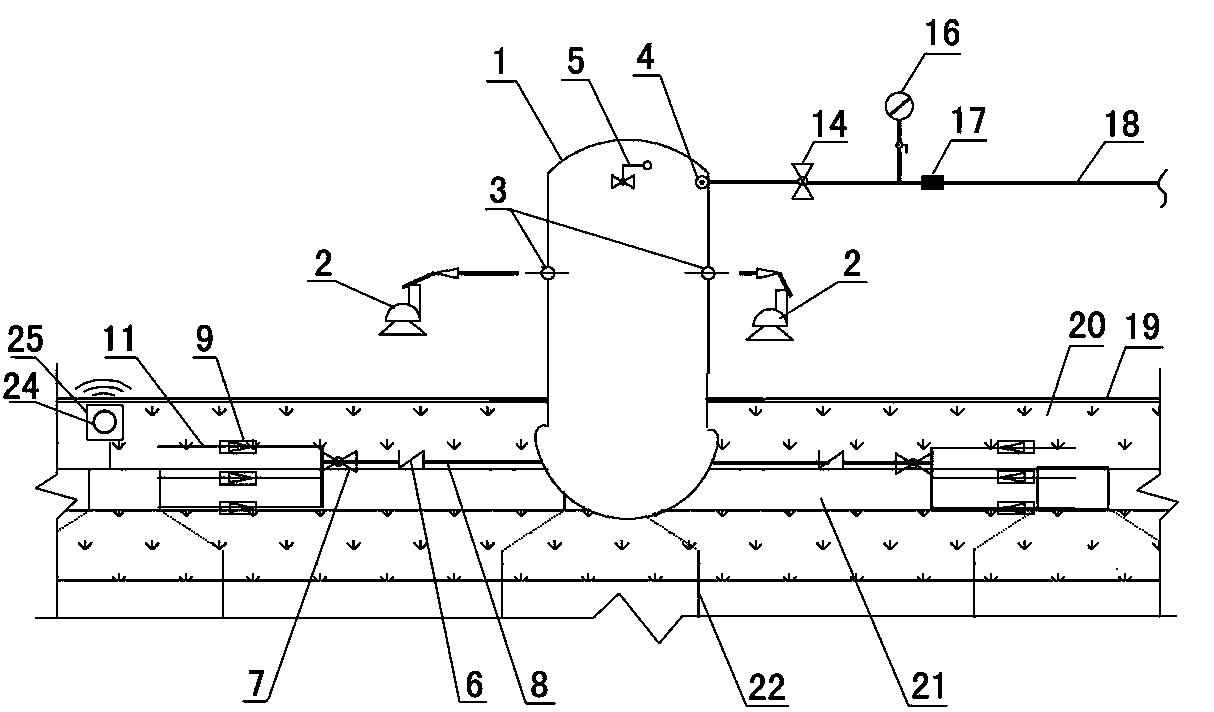

[0042] Embodiment one sees figure 1 , figure 2 As shown, this ultra-large area, high-efficiency and energy-saving vacuuming soft foundation treatment system consists of four parts: vacuuming device, gas-liquid separation device, water collection device and vacuum data automatic transmission device. The vacuuming device is connected with the gas-liquid separation device. The gas-liquid separation device is in communication with the water collection device.

[0043] The vacuum data automatic transmission device is composed of a vacuum data signal sensor 24, a vacuum data automatic transmitter 25 and a vacuum data receiver 26. The vacuum data signal sensor 24 and the vacuum data automatic transmitter 25 are all buried under the sealing film 19. In the sand cushion layer 20.

[0044] The vacuum data signal sensor 24 is made up of a pressure sensing module and a pressure data acquisition module, wherein the pressure sensing module measures the vacuum data (i.e. vacuum degree) in...

Embodiment 2

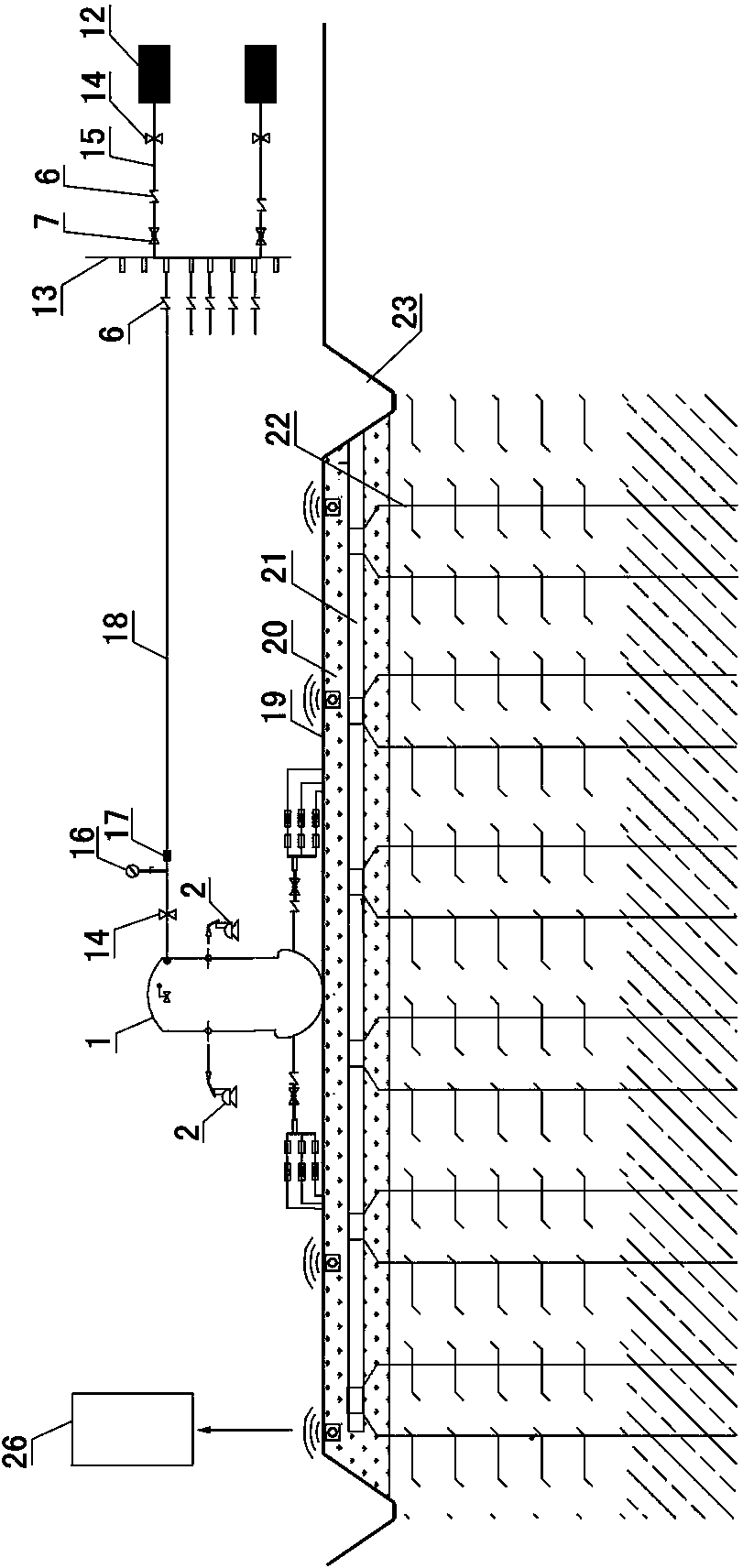

[0051] Embodiment two see image 3 , Figure 4 , the difference from the first embodiment is that the gas-liquid transmission branch pipe 11 in the second embodiment is also provided with a control valve 10 . At the same time, the water storage tank 1 is arranged above the sealing film 19 , and the catchment device passes through the sealing film 19 from top to bottom and is buried in the sand cushion 20 .

[0052] Applying the construction method of the super-large-area high-efficiency energy-saving vacuuming soft ground treatment system, the construction steps are as follows:

[0053] Step 1. Lay woven cloth, brambles and non-woven geotextiles on the foundation to be treated.

[0054] Step 2: Laying medium-coarse sand to form a sand cushion 20. For areas that cannot meet the construction requirements of medium-coarse sand for filling, take reinforcement measures such as laying geotextiles and brambles.

[0055] Step 3, setting up the vertical drainage board 22 and the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com