System and method for avoiding low temperature corrosion of air preheater by using phase change heat

An air preheater, low temperature corrosion technology, applied in combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc. High problems, to achieve the effect of reducing heat exchange area, reducing power consumption, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

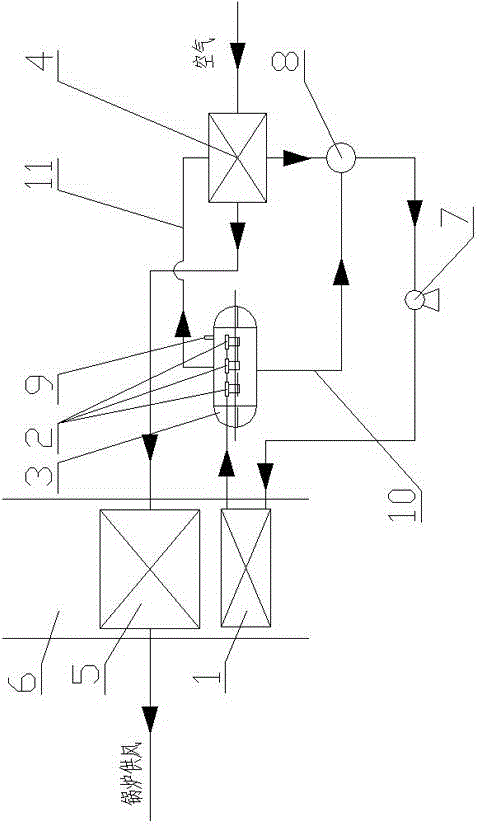

[0018] Specific implementation mode one: as figure 1 As shown, the system for avoiding low-temperature corrosion of the air preheater by using phase-change heat, the system for avoiding low-temperature corrosion of the air preheater by using phase-change heat includes a flue gas cooler 1, a steam-water separator 2, and a steam drum 3 , steam-air heat exchanger 4, air preheater 5, boiler flue 6, low-pressure circulation pump 7, mixer 8 and safety valve 9, boiler flue 6 is arranged at the boiler flue gas outlet, and the flue gas The outlet of the steam and water mixture in the cooler 1 is connected to the inlet of the steam-water separator 2 arranged in the steam drum 3 through a pipeline, and a safety valve 9 is arranged above the steam drum 3, and the steam outlet of the steam drum 3 is connected to the steam-air The steam inlet of the heat exchanger 4 is connected, the condensed water outlet of the steam-air heat exchanger 4 and the downcomer 10 of the steam drum 3 are connec...

specific Embodiment approach 2

[0021] Specific implementation mode two: as figure 1 As shown, the method for avoiding low-temperature corrosion of the air preheater is realized by using the system described in the first embodiment, and the steps of the method are:

[0022] Step 1: The working medium water is heated in the flue gas cooler 1 to obtain a mixture of steam and water. The heating temperature is 102-120°C and the pressure is 0.11-0.20MPa. The steam-water mixture is separated into steam and water by the steam-water separator 2 Separation to obtain saturated steam with a pressure of 0.11-0.20Mpa and a temperature of 102-120°C. The saturated steam is sent into the steam-air heat exchanger 4 through the steam pipeline 11 to exchange heat with the air, and the air is heated to 80-90°C;

[0023] Step 2: On the one hand, the air heated in Step 1 is sent into the air preheater 5 to exchange heat with the hot flue gas to obtain high-temperature air at 200-220°C, and the high-temperature air is sent into th...

Embodiment 1

[0025] Such as figure 1Shown: Taking a 30MW biomass boiler as an example, when the flue gas dew point temperature is lower than 95°C: the working medium (water) is heated in the flue gas cooler 1 to obtain a mixture of steam and water, the heating temperature is 102°C, and the pressure is 0.11 MPa, the steam-water mixture is separated by steam-water separator 2 to obtain saturated steam and saturated water at the pressure and temperature, and saturated steam (pressure 0.11Mpa, temperature 102°C) is sent into steam- The air heat exchanger 4 exchanges heat with the air, and the air is heated to 87-90°C. The hot air is sent into the air preheater 5 to exchange heat with the hot flue gas to obtain high-temperature air at 215-220°C. The high-temperature air is sent to Putting it into the boiler for combustion support can save boiler fuel by 2.0-2.5%. Saturated steam (at a pressure of 0.11MPa and at a temperature of 102°C) undergoes phase-change heat in the steam-air heat exchanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com