Device and method for removing and collecting microparticles in aquaculture water

An aquaculture and micro-particle technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve problems such as large water consumption, untimely backwashing, and inability to reuse, and achieve the effect of ensuring pressure and accurate removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

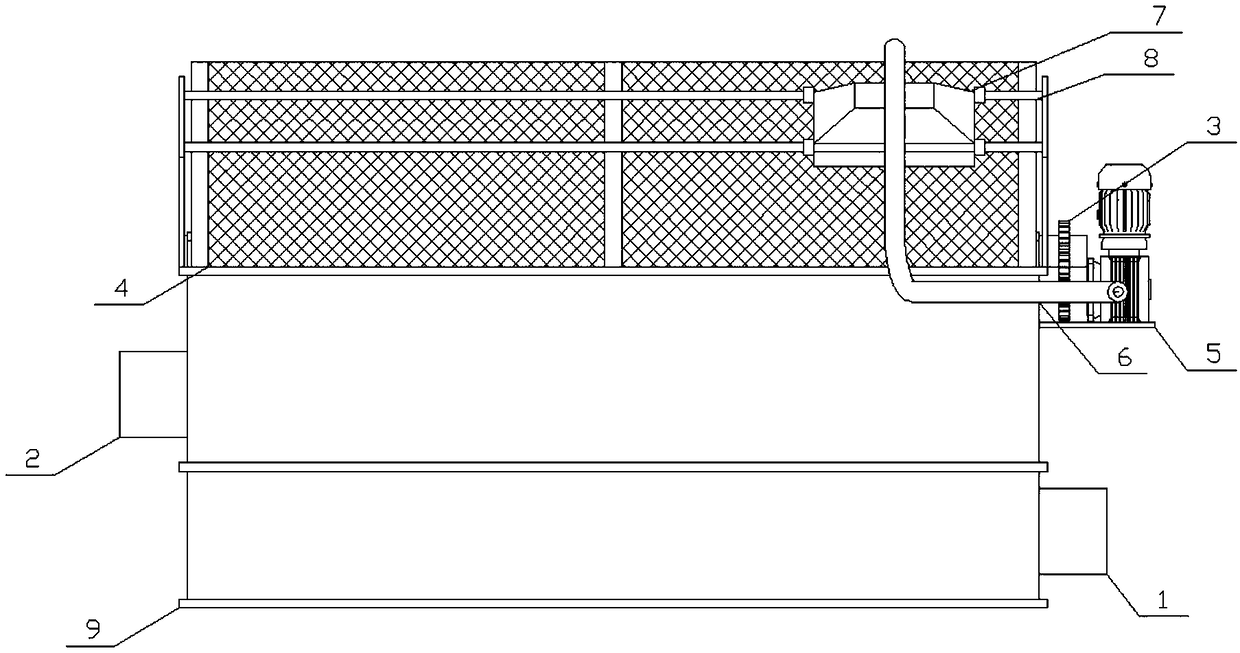

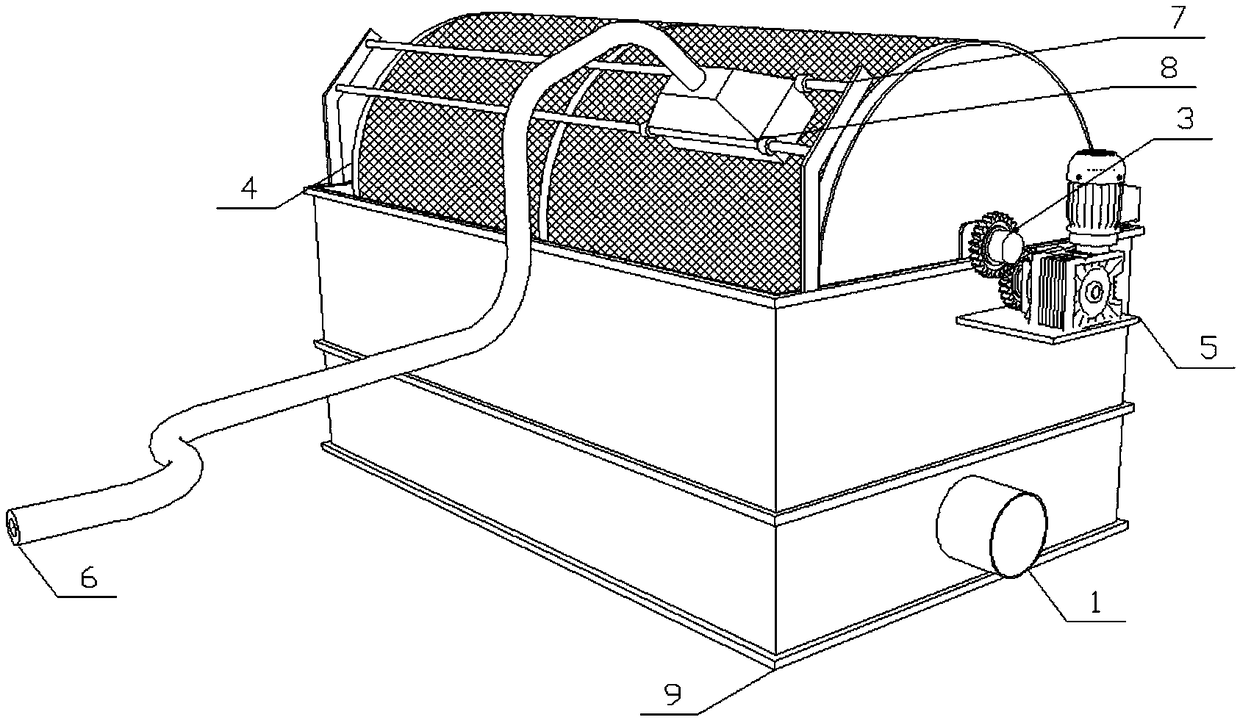

[0023] see Figure 1-Figure 2 A device for removing and collecting microparticles in water bodies for aquaculture, comprising a box body 9 for accommodating water for aquaculture, said box body 9 is provided with a horizontal filter cartridge, and the lower part of the filter cartridge has a distance from the bottom of the box body; The filter cartridge is rotatable driven by the power mechanism; the side wall of the box body 9 is provided with a water inlet 1 and a water outlet 2, and the water inlet 1 is located outside the corresponding part of the end face of the filter cartridge; the water outlet 2 is located at the filter The inside of the corresponding part of the end face of the cylinder; the box body 9 is provided with a slide rail 7, which is arranged along the direction of the filter cartridge busbar, and the slide rail 7 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com