A short process, no water consumption and release paper saving water-based synthetic leather manufacturing method

A manufacturing method and technology of release paper, applied in textiles and papermaking, etc., can solve the problems of low peel strength, low production efficiency, large loss of release paper, etc., to improve market competitiveness, reduce manufacturing process, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of water-based polyurethane back cover slurry, high-solid water-based polyurethane foam slurry, and surface layer slurry, in parts by weight

[0033] a) Preparation of back cover slurry: Mix 100 parts of N-methyldiethanolamine (N-MDEA) cationic waterborne polyurethane with a solid content of 50% and 0.5 part of thickener evenly to obtain a back cover slurry with a viscosity of 3000 Pa•s material;

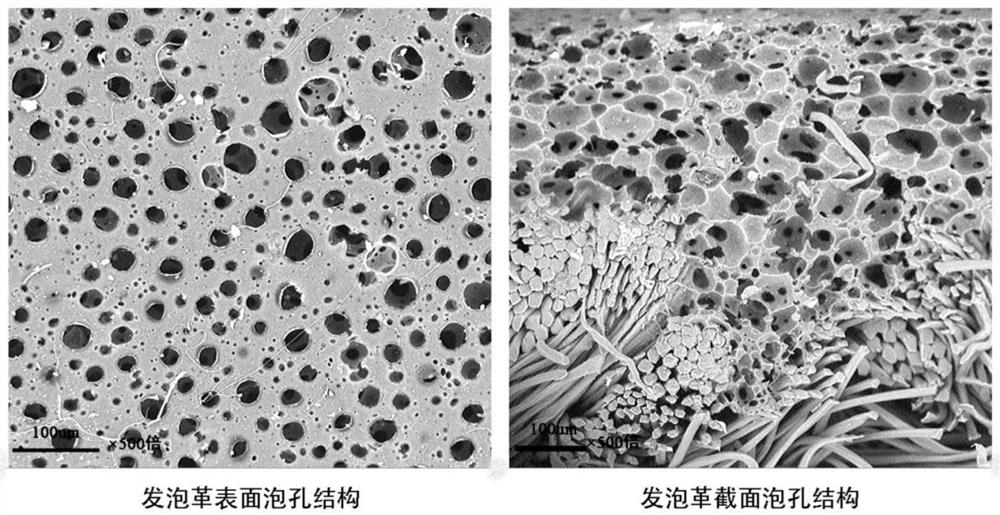

[0034]b) Preparation of foaming slurry: 100 parts of anionic polyether type aliphatic waterborne polyurethane with a solid content of 60%, 0.3 parts of thickener, 2 parts of foam stabilizer, 0.3 parts of leveling agent, 1 part Anionic water-based color paste, 2 parts of water-based crosslinking agent, and 5 parts of filler are mixed evenly, and the foam slurry is made into a foam slurry through an intelligent dynamic generator to obtain a foam slurry with a foaming ratio of 1 to 3 times and a viscosity of 7000Pa•s ;

[0035] c) Preparation of surface layer s...

Embodiment 2

[0043] (1) Preparation of water-based polyurethane back cover slurry, high-solid water-based polyurethane foam slurry, and surface layer slurry, in parts by weight

[0044] a) Preparation of back cover slurry: 100 parts of N-methyldiethanolamine (N-MDEA) cationic waterborne polyurethane and N-propyldiethanolamine (N-BDEA) cationic waterborne polyurethane with a solid content of 35%, 1 Mix one part thickener evenly to obtain a back cover slurry with a viscosity of 4000Pa•s;

[0045] b) Preparation of foaming slurry: 100 parts of anionic polyether type and polycarbonate type aliphatic waterborne polyurethane with a solid content of 55%, 2 parts of thickener, 3 parts of foam stabilizer, 1 part of leveling agent, 3 parts of non-ionic water-based color paste, 3 parts of water-based crosslinking agent, and 10 parts of filler are mixed evenly, and the foam slurry is made into a foam slurry through an intelligent dynamic generator to obtain a foam with a foaming ratio of 2 times and a...

Embodiment 3

[0054] (1) Preparation of water-based polyurethane back cover slurry, high-solid water-based polyurethane foam slurry, and surface layer slurry, in parts by weight

[0055] a) Preparation of back cover slurry: Mix 100 parts of N-ethyldiethanolamine (N-PDEA) cationic waterborne polyurethane with a solid content of 50% and 2 parts of thickener evenly to obtain a back cover slurry with a viscosity of 6000 Pa s material;

[0056] b) Preparation of foaming slurry: 100 parts of anionic polycarbonate aromatic waterborne polyurethane with a solid content of 50%, 3 parts of thickener, 5 parts of foam stabilizer, 1.7 parts of leveling agent, 5 parts of anion and Mix non-ionic water-based color paste, 5 parts of water-based cross-linking agent, and 20 parts of filler evenly, and make a foam slurry through an intelligent dynamic generator to obtain a foaming slurry with a foaming ratio of 3 times and a viscosity of 9000 Pa·s;

[0057] c) Preparation of surface layer slurry: 100 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com