Flue gas desulfurization absorber interactive spray system

A desulfurization absorption tower and spray system technology, applied in the field of flue gas desulfurization absorption tower interactive spray system, can solve the problems of large deformation of the main pipe, uneven nozzle flow, large change of pipe diameter, etc., to increase height and shorten Renovation construction period and effect of reducing remodeling workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

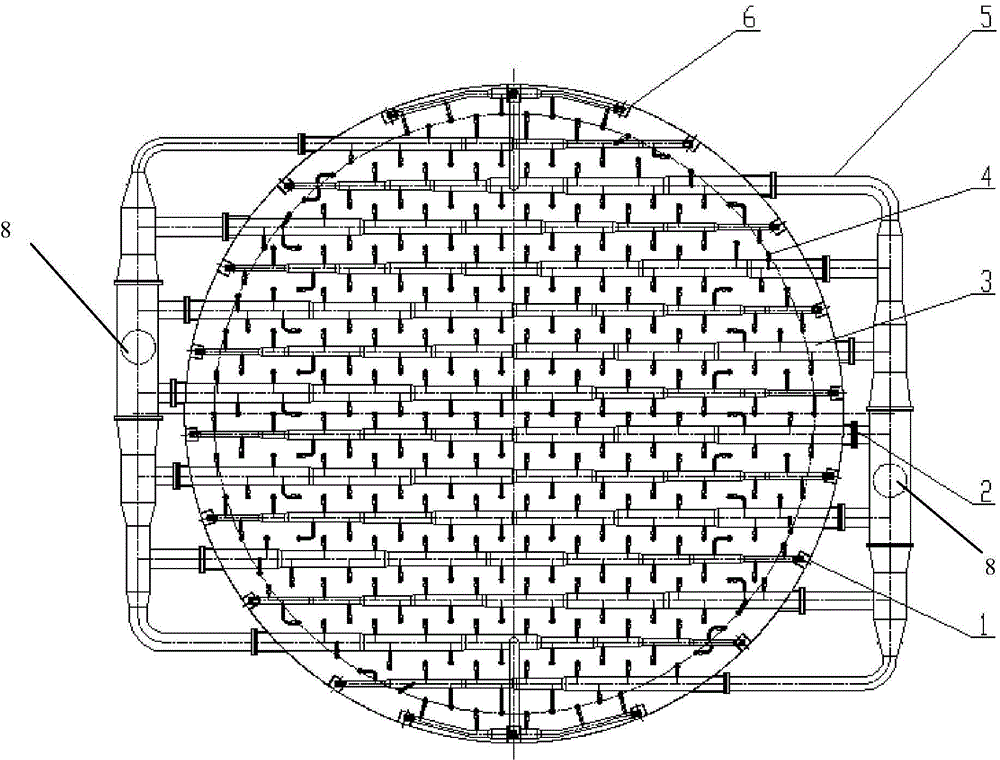

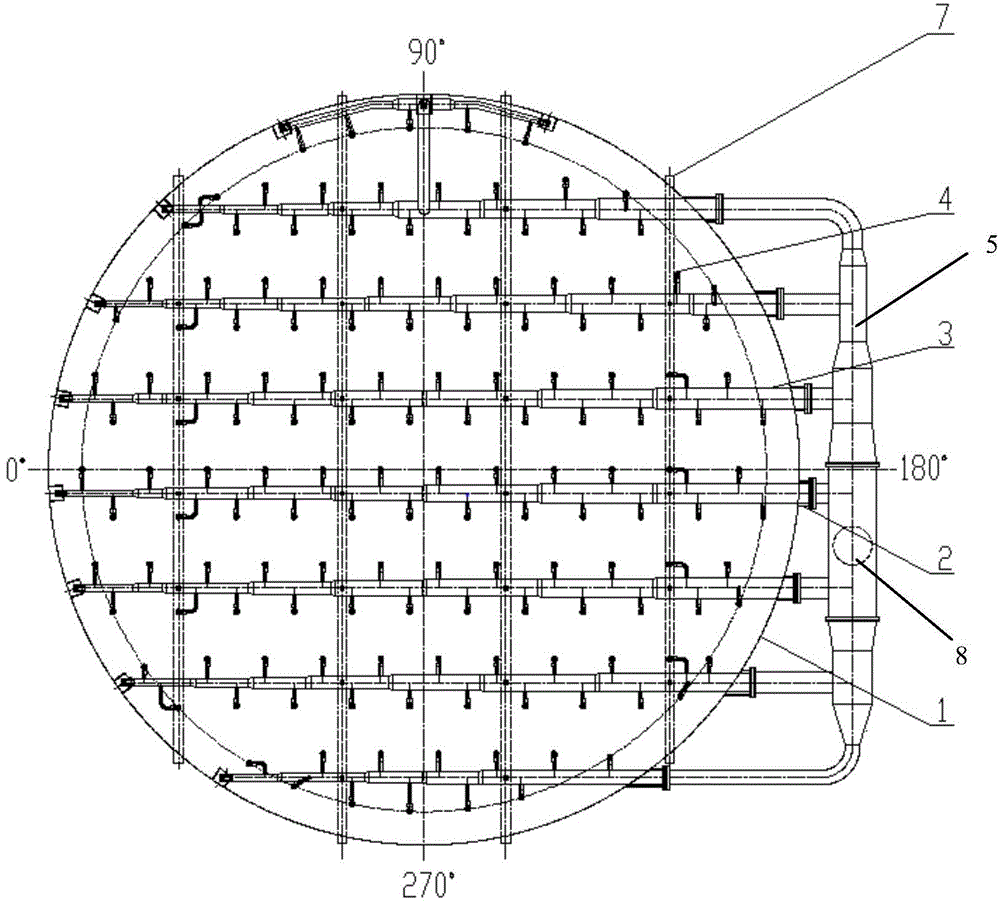

[0017] The circulating interactive spray system of the desulfurization absorption tower of the present invention can be arranged in layers in the absorption tower 1, and the spray slurry is limestone slurry, which is transported from the slurry area at the bottom of the absorption tower through the external circulation slurry pipe 5 to the spray mother via the circulating slurry pump. The pipe is sprayed and circulated continuously. Each spray layer is mainly com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com