SCR flue gas denitration optimization control system and method based on ammonia spraying amount compensator

A technology for optimized control and ammonia injection volume, applied in the general control system, control/regulation system, adaptive control, etc., can solve problems such as poor control effect of ammonia injection volume, influence on denitrification efficiency, secondary environmental pollution, etc., and achieve reduction The effect of denitrification operation cost, reduction of ammonia escape rate, and avoidance of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

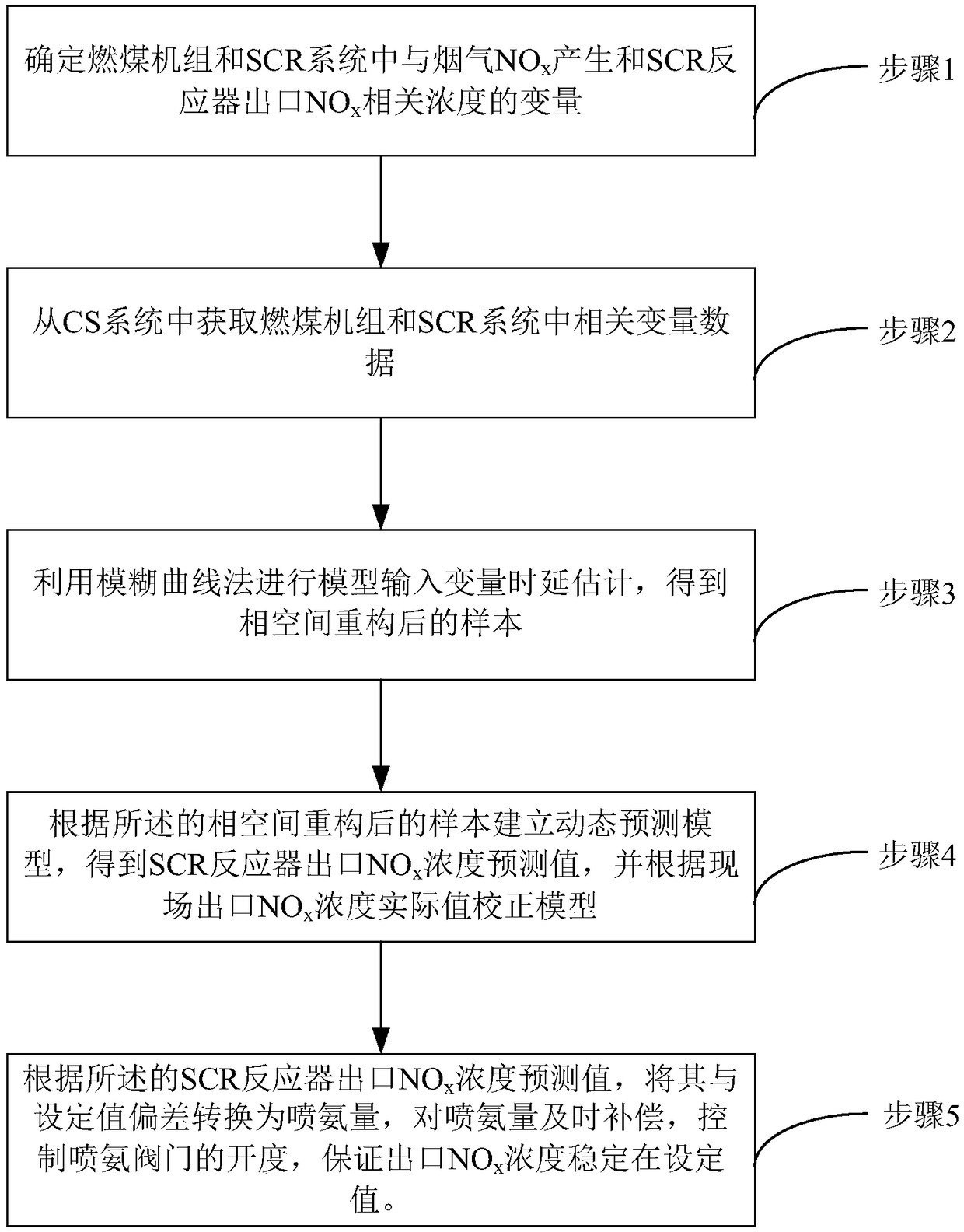

[0040] Such as figure 1 As shown, what is described in the embodiment of the present invention is an optimal control method for SCR flue gas denitrification based on an ammonia injection amount compensator, the method comprising:

[0041] Step 1. Determine the amount of flue gas NO in coal-fired units and SCR systems x Produced and SCR reactor outlet NO x Concentration-related variables;

[0042] Step 2, obtain relevant variable data in step 1 from the DCS system;

[0043] Step 3, use the fuzzy curve method to estimate the time delay of the input variable of the model, and obtain the sample after phase space reconstruction;

[0044] Step 4. Establish exit NO according to the sample after phase space reconstruction in step 3 x Concentration dynamic prediction model to obtain NO at the outlet of the SCR reactor x Concentration prediction value, and export NO according to the field x Concentration actual value correction outlet NO x Concentration dynamic prediction model; ...

Embodiment 2

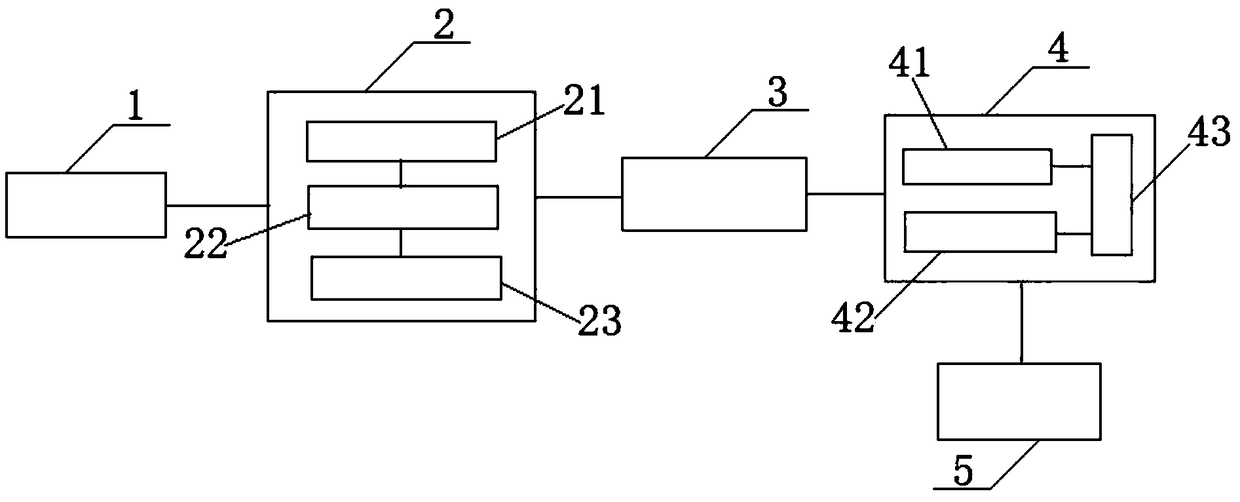

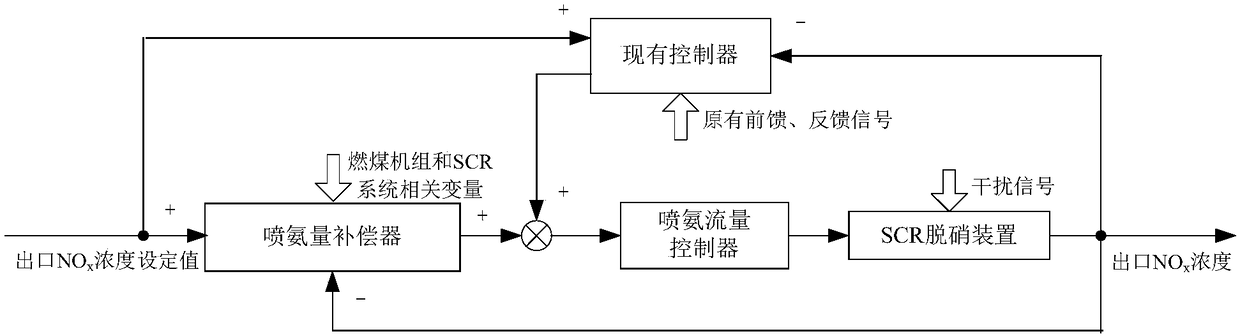

[0064] Such as Figure 2-3 As shown, the embodiment of the present invention is a SCR flue gas denitrification optimization control device based on the ammonia injection amount compensator, which includes:

[0065] Ammonia injection amount compensator algorithm processor 2, its input end is connected with data collector 1, output end of ammonia injection amount compensator algorithm processor 2 is connected with input end of improved DCS system 3, ammonia injection amount compensator algorithm processor 2 It includes a phase space reconstruction device 21 , an outlet NOx concentration dynamic prediction model device 22 and an ammonia injection compensation calculation device 23 . The phase space reconstruction device 21 , the outlet NOx concentration dynamic prediction model device 22 and the ammonia injection compensation amount calculation device 23 are set inside the ammonia injection amount compensator algorithm processor 2 .

[0066] The field controller 4, its input end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com