Method for reducing ammonia escaping rate of flume denitration outlet

A technology for ammonia escape rate and flue gas, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve problems such as downstream rotary preheater blockage, lower denitrification efficiency, and atmospheric secondary pollution, etc., and achieve reduction Improvement costs and operating costs, reduce complexity, and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing and example.

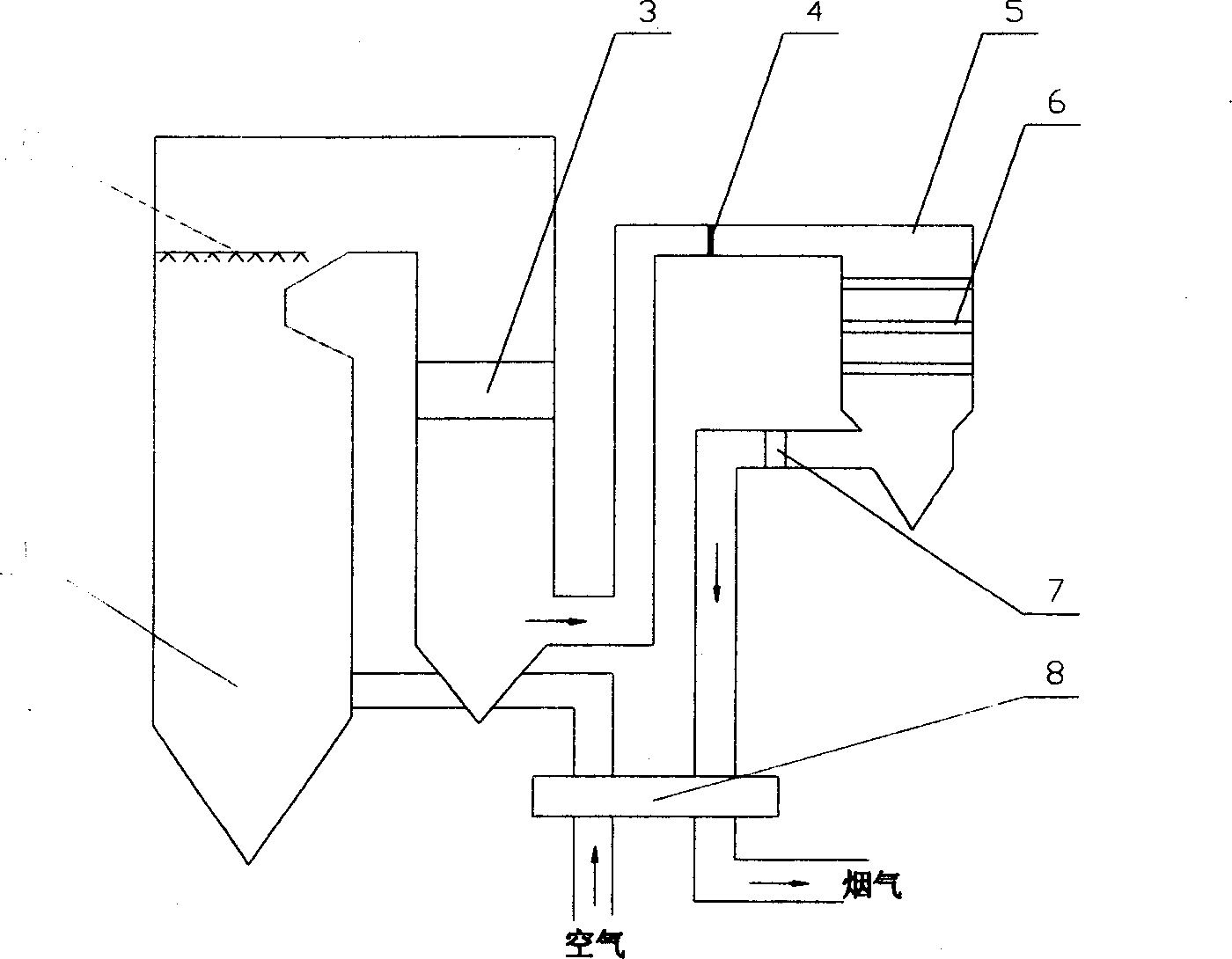

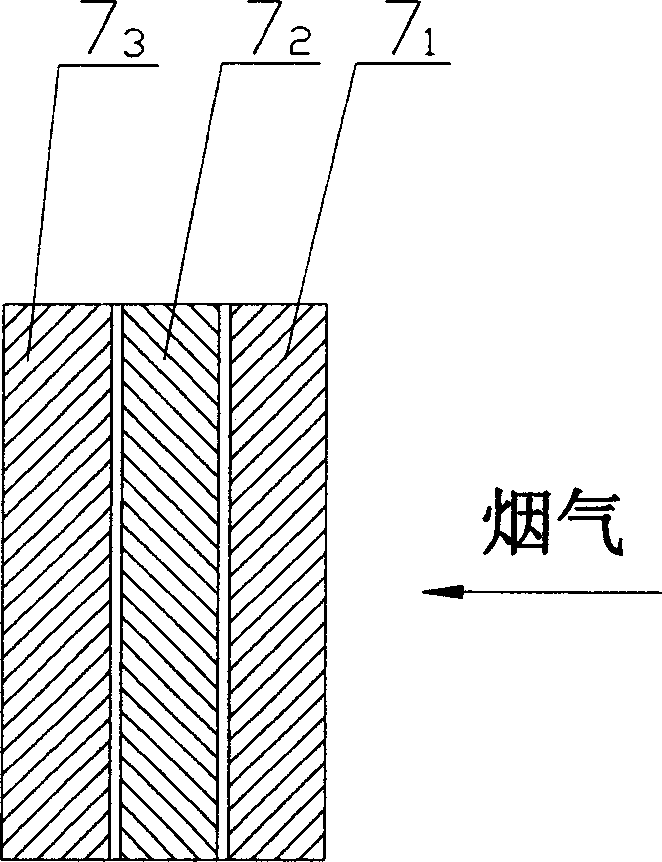

[0010] Examples of the present invention are figure 1 , the flue gas produced after the combustion of boiler 1 passes through the ammonia injection point 2 of the SNCR method, the boiler economizer 3, the ammonia injection point 4 of the SCR method, the SCR reactor 5, and the molecular sieve reactor 7, then passes through the air preheater 8, and then enters In the next step, the flue gas treatment facilities such as electrostatic precipitator and flue gas desulfurization device are discharged into the atmosphere through the chimney. Among them, SNCR method ammonia injection point 2, SCR method ammonia injection point 4, SCR reactor 5, and catalyst bed 6 are optional. When using SNCR denitrification process, there is only SNCR method ammonia injection point 2; when using SCR denitrification process, only SCR ammonia injection point 4, SCR reactor 5 and catalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com