Process and device for carrying out flue gas denitrification by utilizing solid organic denitrifying agent

A denitration agent and organic technology, applied in the field of industrial flue gas denitration, to achieve the effect of improving denitration efficiency, advanced equipment and technology, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

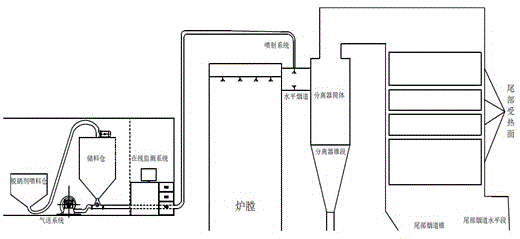

Method used

Image

Examples

Embodiment 1

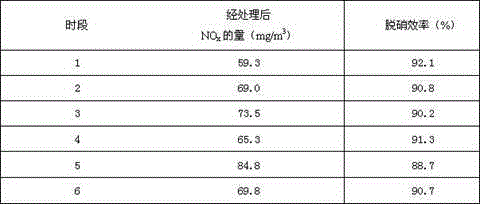

[0035] NO in flue gas to be treated x The initial concentration of 450 mg / m 3 , the flue temperature is within the range of 850°C~950°C, spray 53.30kg of solid organic denitration agent into the flue reactor every hour, and its specific components are 34.65kg of acetamide, 5.33kg of ammonium bicarbonate, 13.32kg of active calcium carbonate, with NO x The mass ratio of the reaction is 1.2:1, and the treated flue gas enters the online monitoring system for real-time monitoring.

[0036] Table 1 Flue gas denitrification efficiency in different periods

[0037]

Embodiment 2

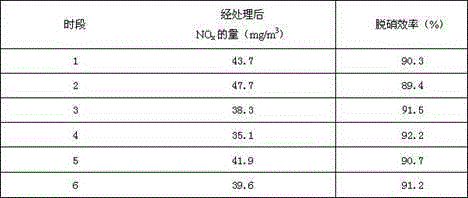

[0039] As described in Example 1, the difference is: when the flue temperature is within the range of 650°C to 800°C, 63.79kg of solid organic denitration agent is sprayed into the flue reactor every hour, and its specific composition is 41.46kg of triammonium citrate, Ammonium bicarbonate 6.38kg, active calcium carbonate 15.95kg, and NO x The mass ratio of the reaction is 1.5:1, and the treated flue gas enters the online monitoring system for real-time monitoring.

[0040] Table 2 Flue gas denitrification efficiency in different periods

[0041]

Embodiment 3

[0043] NO in flue gas to be treated x The initial concentration of 750 mg / m 3, the flue temperature is within the range of 850°C~950°C, spray 232.88kg of solid organic denitration agent into the flue reactor every hour, and its specific components are 151.37kg of acetamide, 23.29kg of ammonium bicarbonate, 58.22kg of active calcium carbonate, with NO x The mass ratio of the reaction is 1.5:1, and the treated flue gas enters the online monitoring system for real-time monitoring.

[0044] Table 3 Flue gas denitrification efficiency in different time periods

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com