Grease injection device

A grease injection device and grease injection technology are applied to engine components, engine lubrication, mechanical equipment, etc., which can solve problems such as ineffective control of grease injection volume, skin corrosion, and increased defect rate, so as to ensure personal health and safety, The effect of reducing cost waste and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

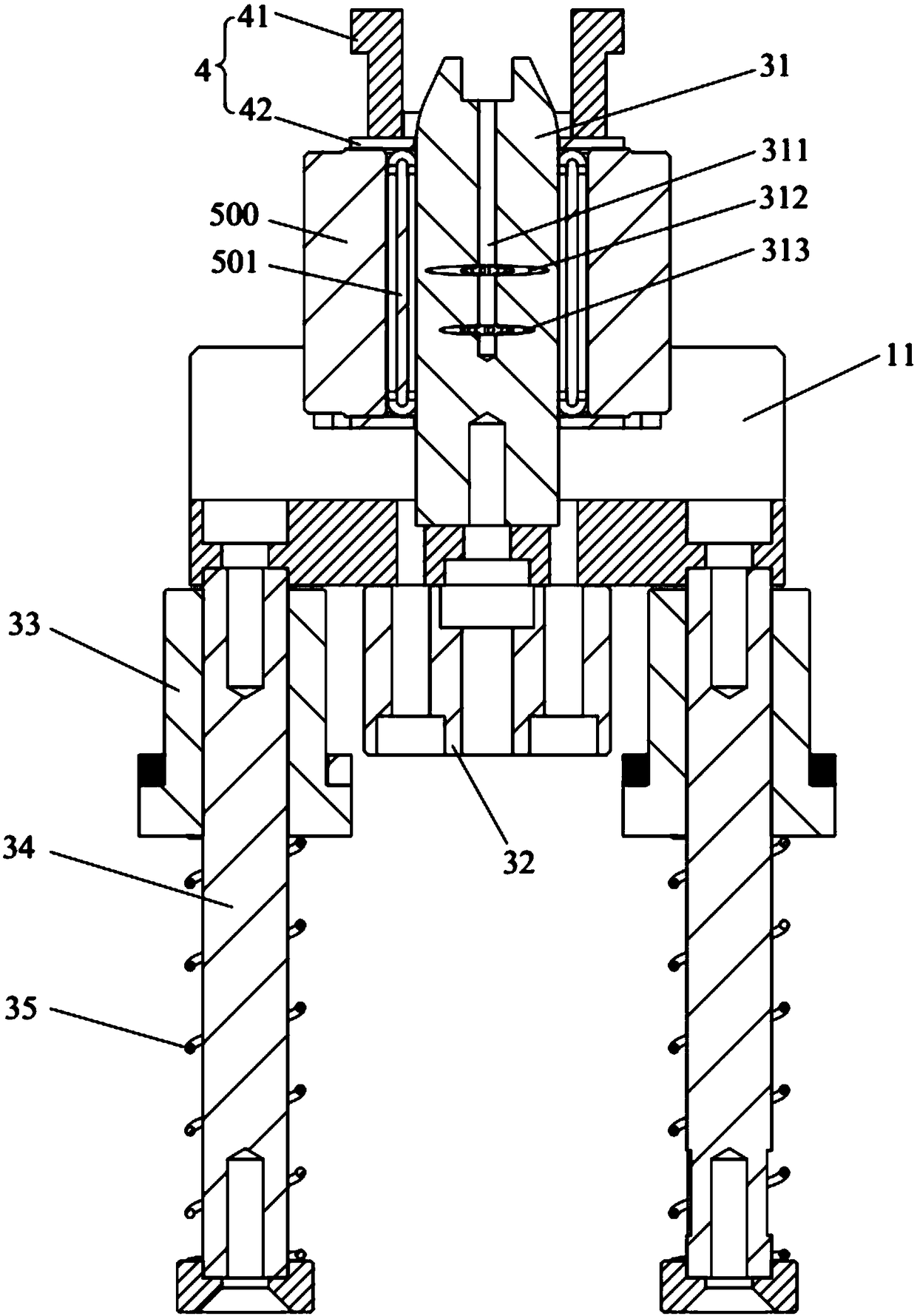

[0041] This embodiment provides a grease injection device, which can inject grease into the needle roller 501 in the helical gear and lubricate the needle roller 501, so that the automobile shaft can effectively reduce the wear when it rotates.

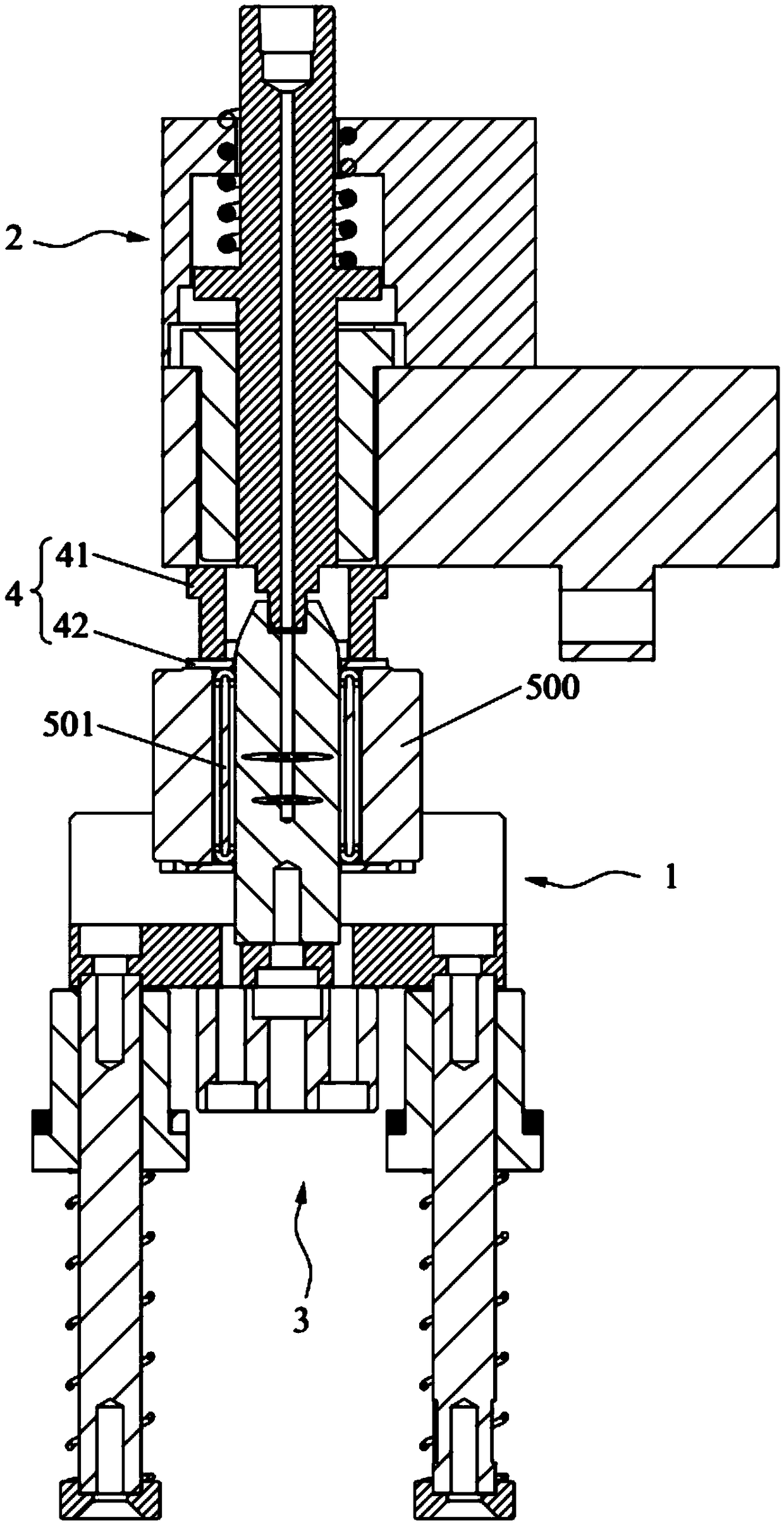

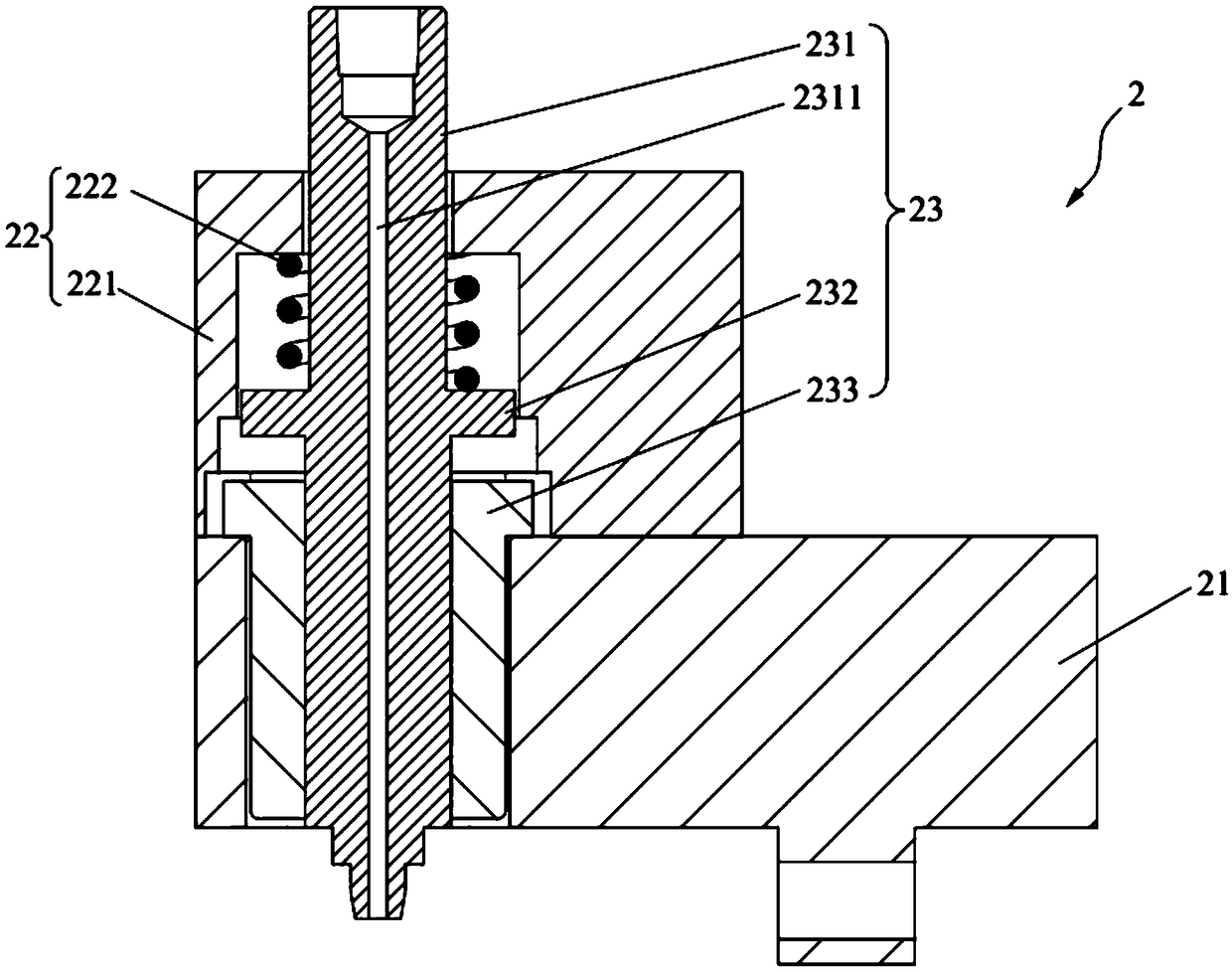

[0042] The grease injection device provided in this embodiment, such as figure 1 As shown, the grease injection device includes a positioning mechanism 1, a grease delivery mechanism 2 and a grease injection mechanism 3, wherein the positioning mechanism 1 is used for positioning a workpiece 500, and the workpiece 500 is specifically a differential helical gear, inside the differential helical gear Eighteen needle rollers are installed, and the grease transfer mechanism 2 and the grease injection mechanism 3 cooperate to inject grease into the needle roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com