A safety automatic operating device

An automatic operation and bumper technology, applied in safety devices, offensive equipment, weapon accessories, etc., can solve the problems of test personnel's personal health and safety hazards, low degree of automation, and life danger, so as to ensure personal health and safety and improve the degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

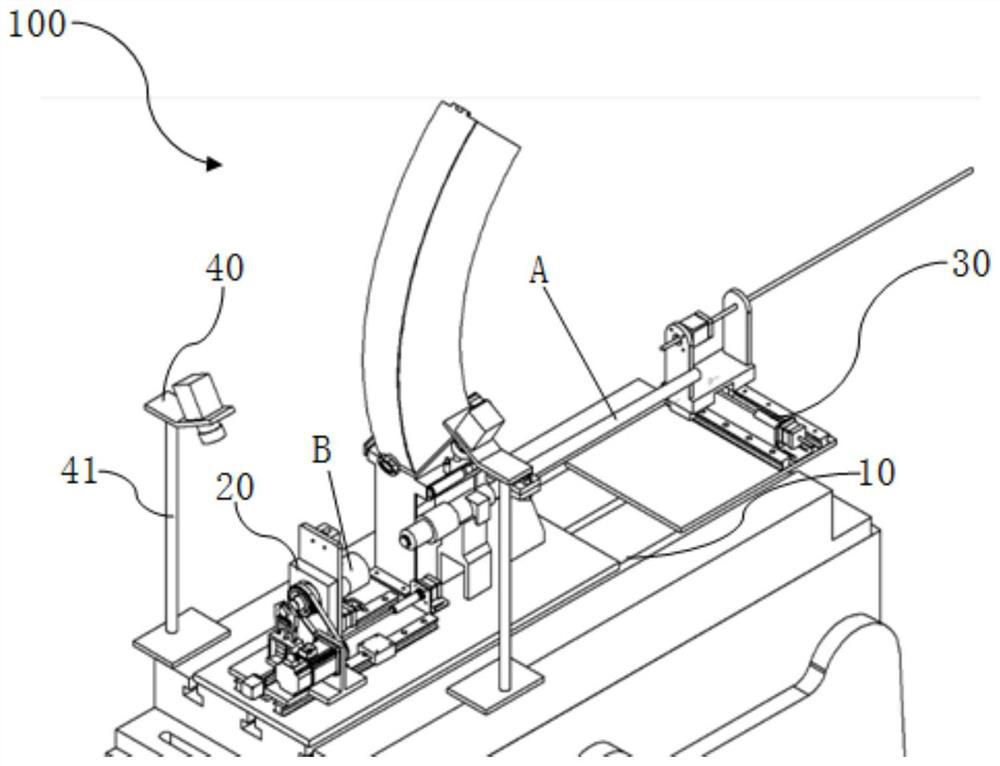

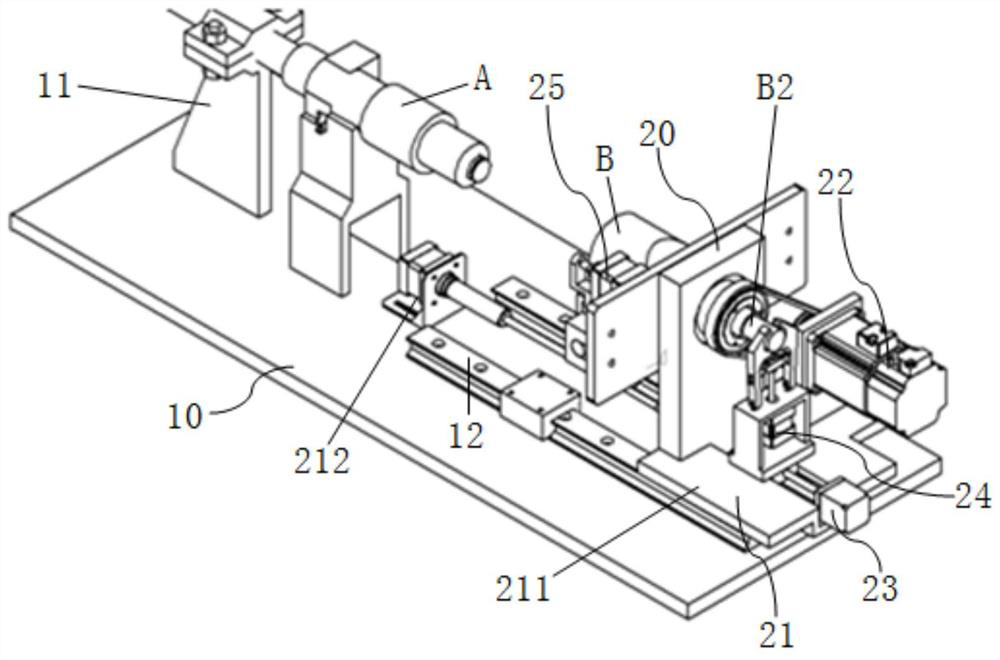

[0037] In order to make the technical means, creative features, goals and effects realized by the present invention easy to understand, the following embodiments will specifically describe an automatic insurance operation device of the present invention in conjunction with the accompanying drawings. It should be noted that the description of these embodiments It is used to help the understanding of the present invention, but does not constitute a limitation of the present invention.

[0038] like figure 1 As shown, the rear cover B and the gun barrel of the 12.7mm caliber gun type firearm in this embodiment are both straight and are coaxially arranged together through threaded connections.

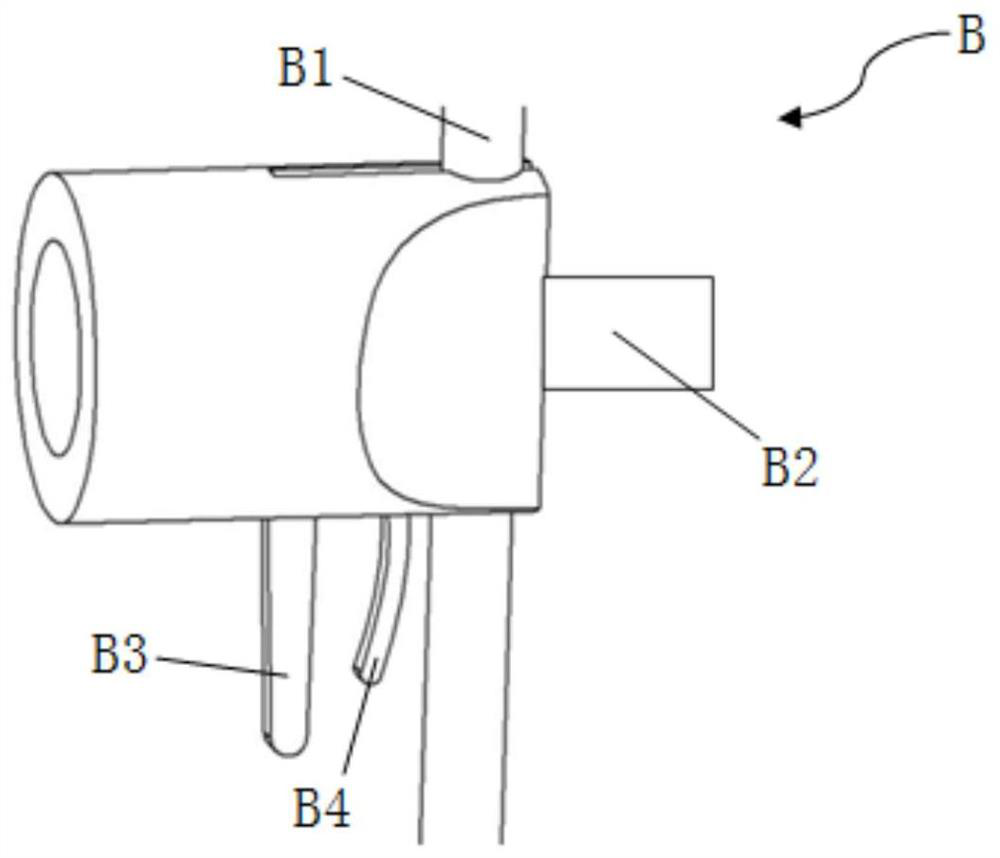

[0039] The end of the barrel has a muzzle for firing bullets, and the back cover B includes a handle B1, a firing pin B2, a safety lever B3 and a trigger B4.

[0040] The handle B1 is used for holding and is fixedly installed on the end side wall of the back cover B, and is perpendicular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com