Combined denitration method and combined denitration device for flue gas of hazardous waste incineration system

A flue gas and denitrification technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as difficulty in meeting nitrogen oxide emission standards, reducing the actual processing capacity of the incineration system, and reducing the service life of equipment, etc. The effect of reducing the operating cost of denitration, small changes, and reducing the amount of injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

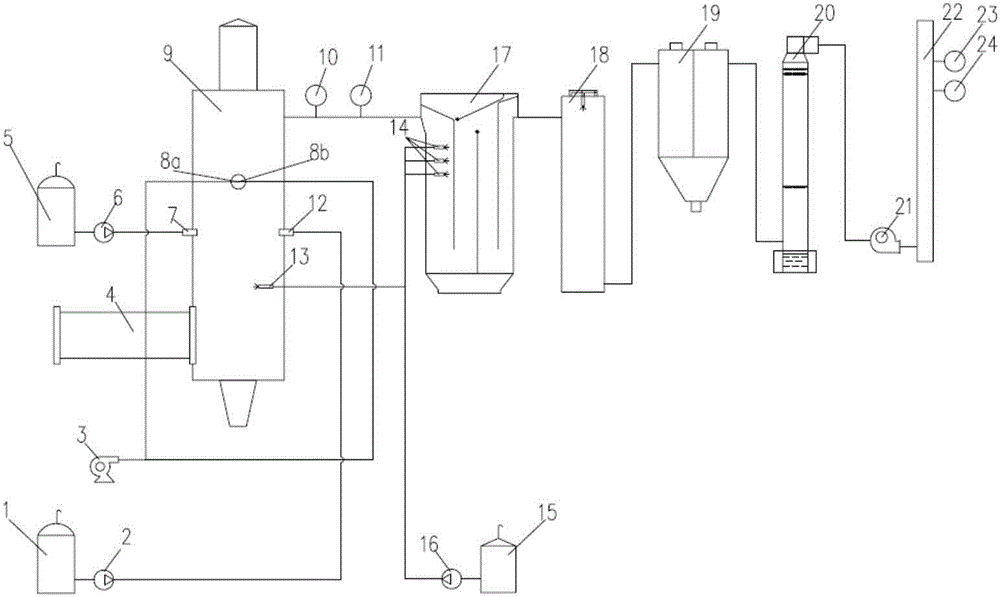

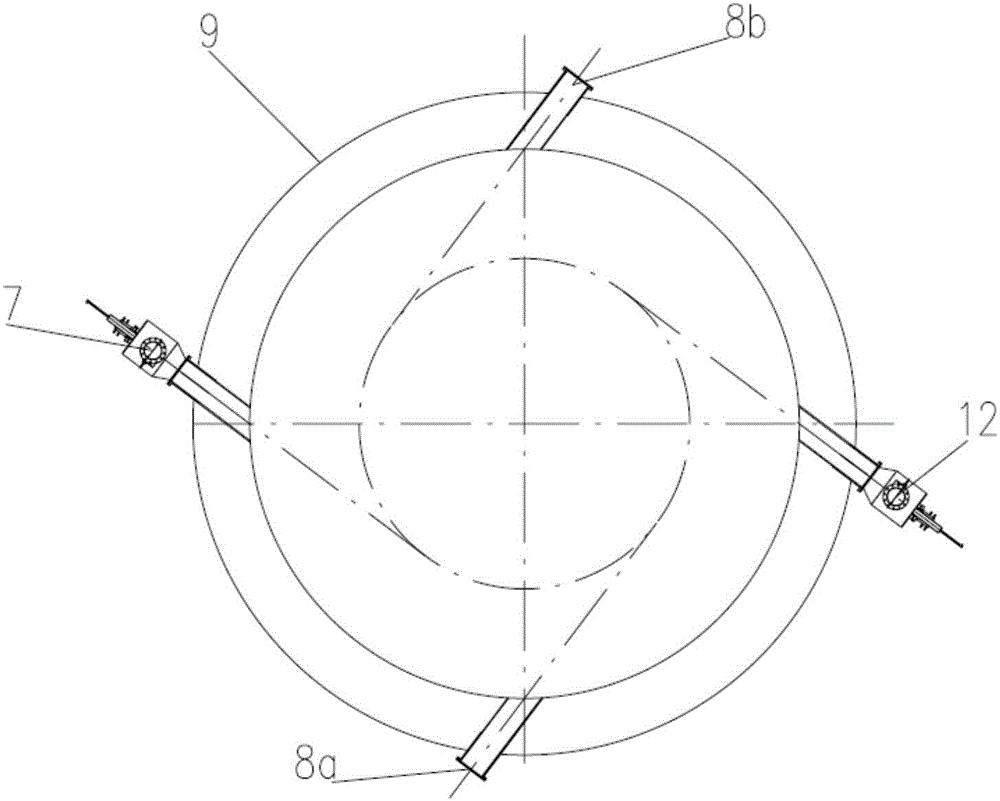

[0028] figure 1 It is a structural schematic diagram of the flue gas combined denitrification device of the hazardous waste incineration system of the present invention, figure 2 It is a schematic diagram of the plane layout of the reburning fuel spray gun in the second combustion chamber, such as figure 1 and figure 2 As shown, the device adopts a combination of organic liquid waste, light diesel reburning denitrification and selective non-catalytic reduction denitrification (SNCR). The device mainly includes: rotary kiln 4, secondary combustion chamber 9, waste heat boiler 17, quenching tower 18, bag filter 19, wet deacidification tower 20, induced draft fan 21 and chimney 22. The second combustion chamber 9 is mainly used for reburning denitration of organic liquid waste, light diesel oil and SNCR denitrification of some ammonia wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com