Device and method for denitration on flue gas by coupling selective non catalytic reduction and catalytic reduction

A non-catalytic and selective technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of secondary pollution, high investment and operating costs, large installation space, etc., to save space and reduce investment. and operating costs, the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

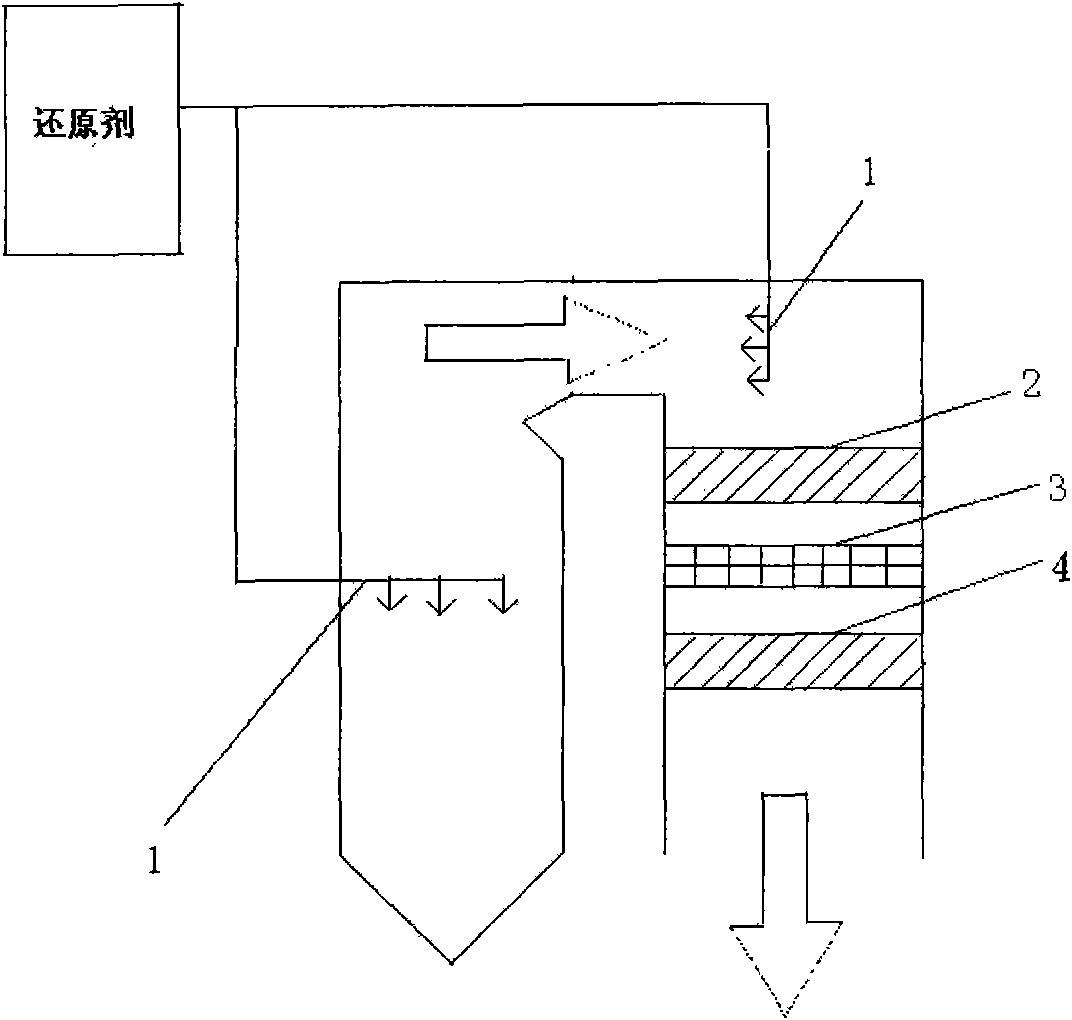

[0025] see figure 1 The flue gas denitrification device of the first scheme of the present invention includes multiple groups of spray guns 1 for injecting reducing agent installed in two layers in the furnace, and an economizer 2 arranged in sequence along the flow direction of the flue gas in the flue, a medium-temperature catalyst 3, and an air preheater. Heater 4.

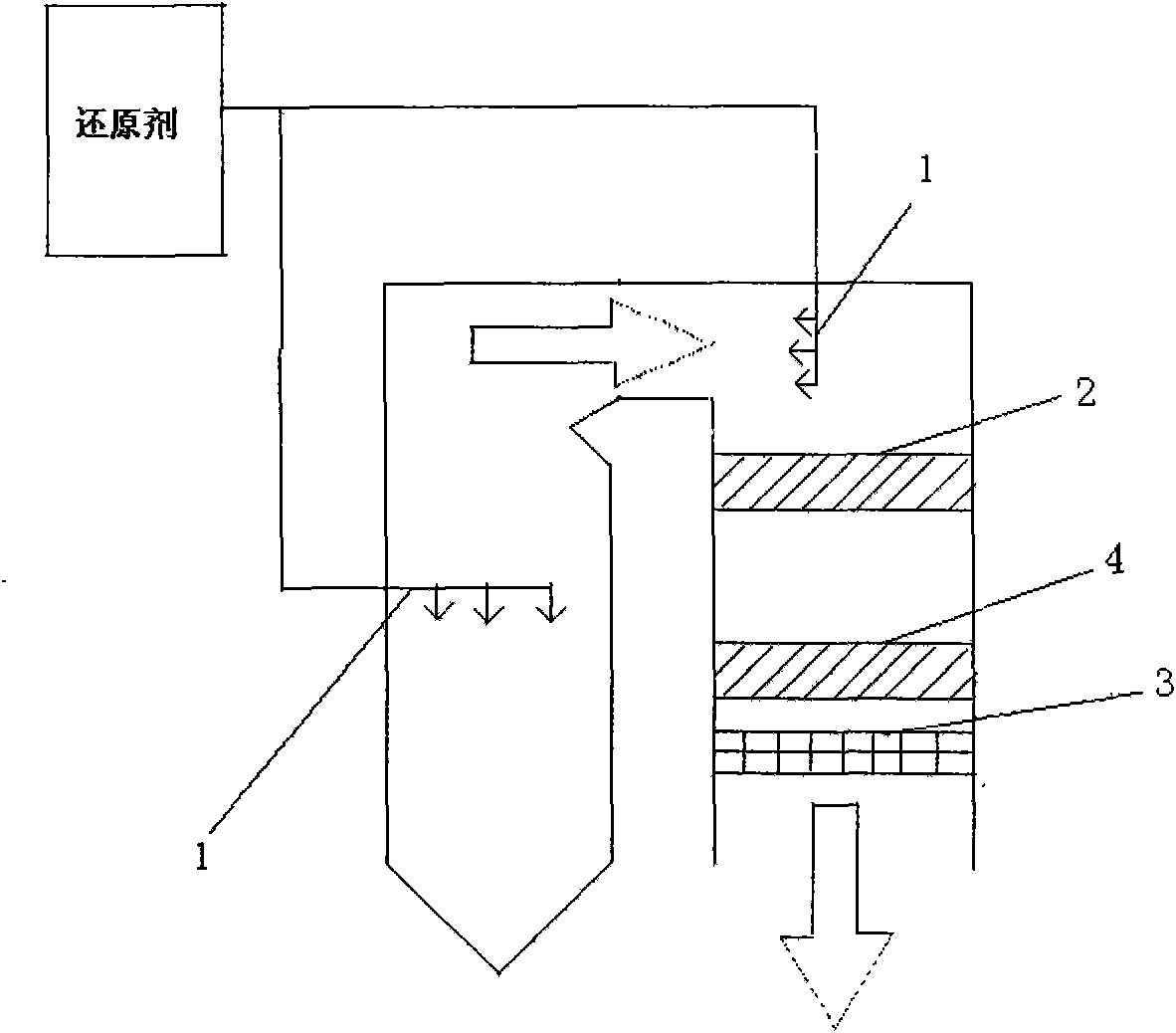

[0026] see figure 2 The flue gas denitrification device of the second scheme of the present invention includes multiple groups of spray guns 1 for injecting reducing agent installed in two layers in the furnace, and an economizer 2, an air preheater 4, a low temperature Catalyst 3.

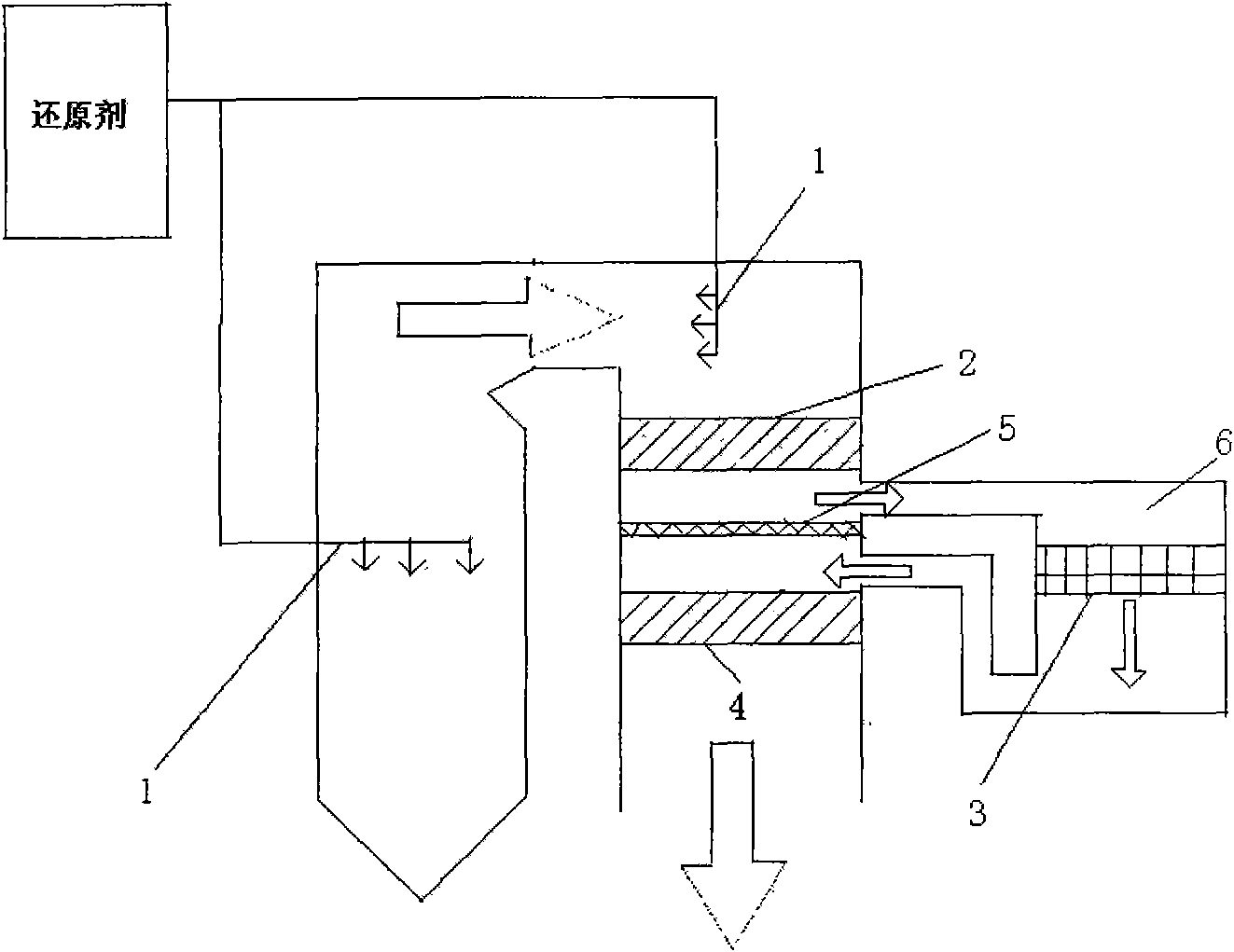

[0027] see image 3 The flue gas denitrification device of the third scheme of the present invention includes multiple groups of spray guns 1 for spraying reducing agents installed in two layers in the furnace, an economizer 2 in the flue, a medium-temperature catalyst 3 in the SCR reactor 6, and air in the flue. Preheater4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com