Honeycomb type low-temperature denitration method and device thereof

A low-temperature denitrification, honeycomb technology, applied in the direction of separation methods, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem that the simulation effect is different from the actual use situation, and cannot be evaluated very well Denitrification catalysts, unfavorable industrialization of denitrification catalysts, etc., to achieve the effects of avoiding poisoning, short preparation cycle and stable efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

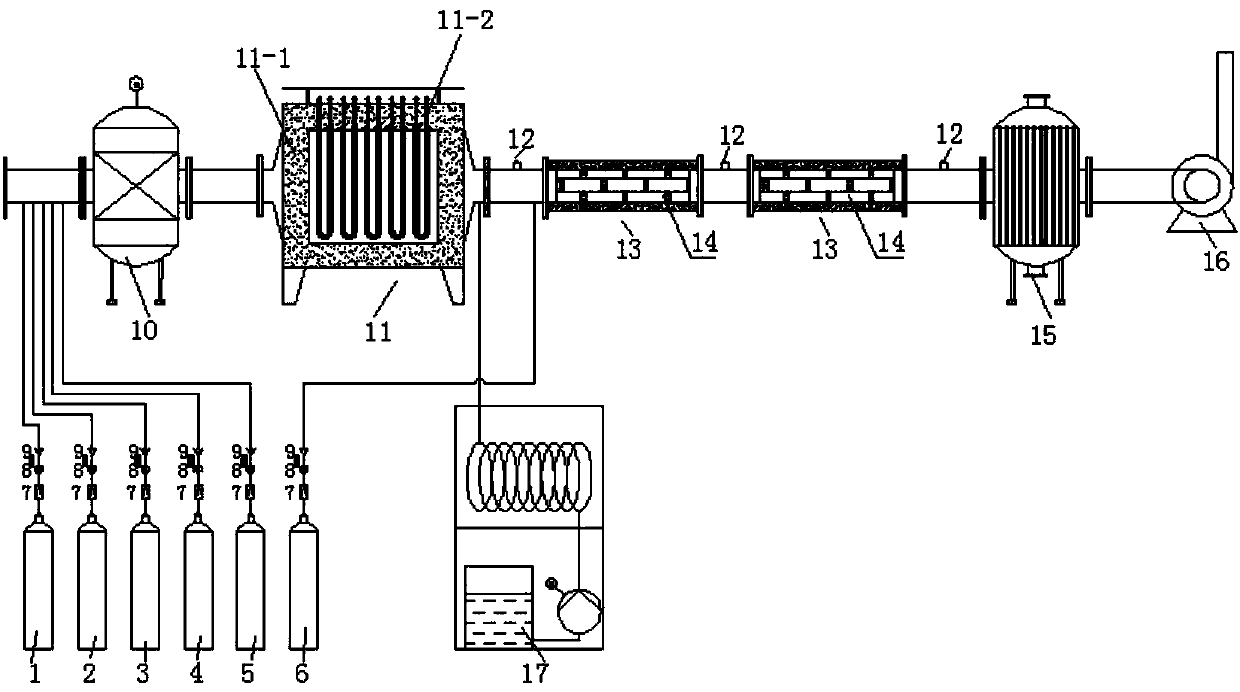

Method used

Image

Examples

Embodiment 1

[0044] Catalyst activity evaluation Catalyst usage is 4 pieces of 100mm×100mm×150mm honeycomb cordierite-based catalysts, reacted in a fixed bed reactor, the flow rate is controlled by a mass flow meter, and the reaction conditions are [NH 3 ] / [NO]=1, the amount of NO is 200ppm, NH 3 =200ppm, the flow rate is 10m 3 / h. The test is carried out according to the following temperature gradient, and the specific data are as follows:

[0045] temperature °C

Embodiment 2

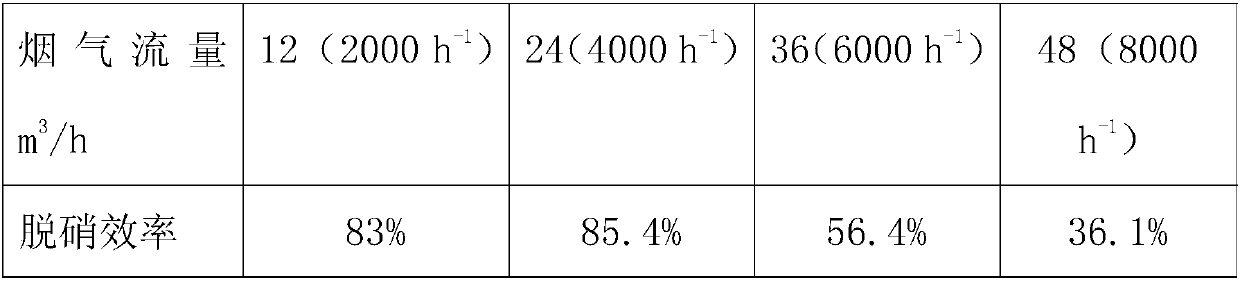

[0047] Catalyst activity evaluation Catalyst usage is 4 pieces of 100mm×100mm×150mm honeycomb cordierite-based catalysts, reacted in a fixed bed reactor, the flow rate is controlled by a mass flow meter, and the reaction conditions are [NH 3 ] / [NO]=1, the amount of NO is 200ppm, NH 3 = 200ppm. At a temperature of 100°C, by changing the flue gas flow rate to change the space velocity, the flue gas flow rate changes as the following gradient, and the results are as follows:

[0048]

Embodiment 3

[0050] Catalyst activity evaluation Catalyst usage is 4 pieces of 100mm×100mm×150mm honeycomb cordierite-based catalysts, reacted in a fixed bed reactor, the flow rate is controlled by a mass flow meter, the reaction conditions are temperature 100°C, the amount of NO is 200ppm, and the flow rate is 10m 3 / h,. Change [NH 3 ] / [NO] ratio, the NO removal rate was determined by the flue gas analyzer. Five data were measured at intervals under each condition. The result is as follows:

[0051] [NH 3 ] / [NO]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com