Denitrating coal economizer high-temperature bypass device

A technology of bypass device and economizer, applied in chemical instruments and methods, combustion product treatment, combustion methods, etc., can solve the problems of downstream air preheater clogging, reduced denitrification effect, corrosion, etc., to improve the use of Efficiency, denitrification efficiency inhibition, effect of improving denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

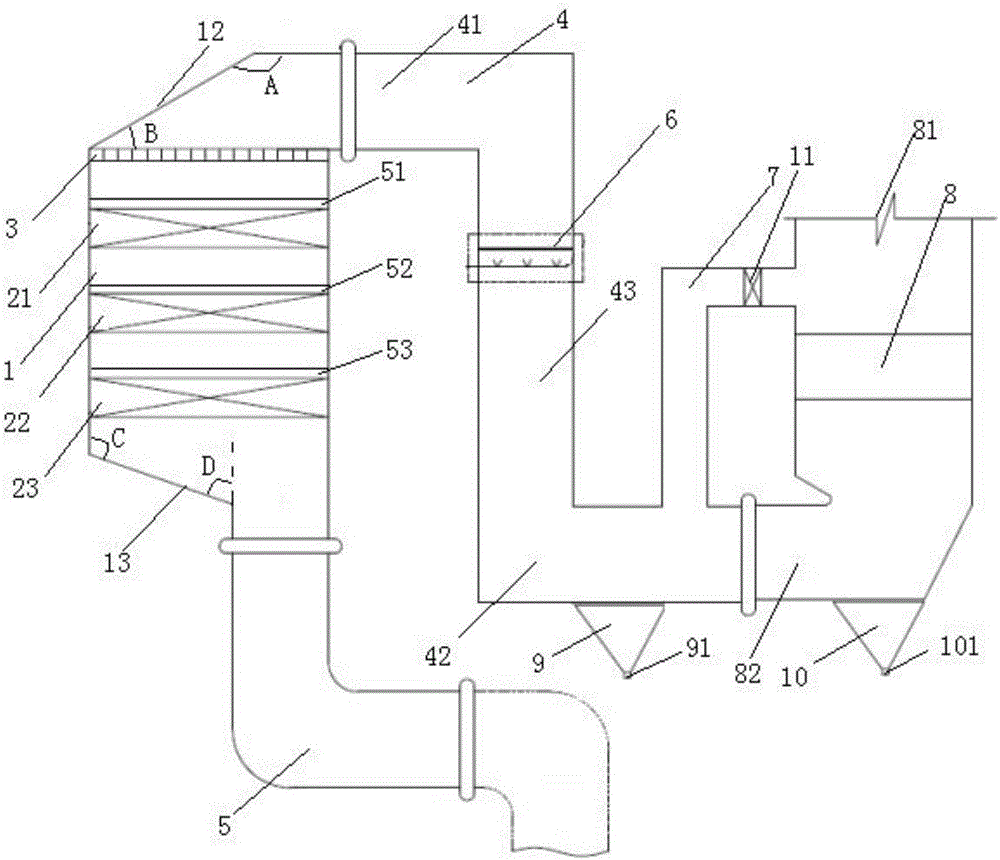

[0046] Example 1, such as figure 1 As shown, a high-temperature bypass device for a denitrification economizer described in an embodiment of the present invention includes an economizer 8 and an economizer bypass flue 7, and the inlet end of the economizer bypass flue 7 is connected to the economizer One side of the economizer 8 is connected, the entrance of the economizer bypass flue 7 is provided with an electric baffle door 11, the top of the economizer 8 is provided with an economizer inlet 81, and one side of the bottom of the economizer 8 is provided with an economizer Economizer outlet 82, economizer 8 bottom is provided with economizer outlet ash hopper 10, economizer outlet 82, outlet end of economizer bypass flue 7 and vertical flue 43 of desulfurization reactor inlet flue 4 connected, the vertical flue 43 is provided with an ammonia injection grid 6, the first horizontal flue 41 of the inlet flue 4 of the desulfurization reactor is connected with the top of the desu...

Embodiment 2

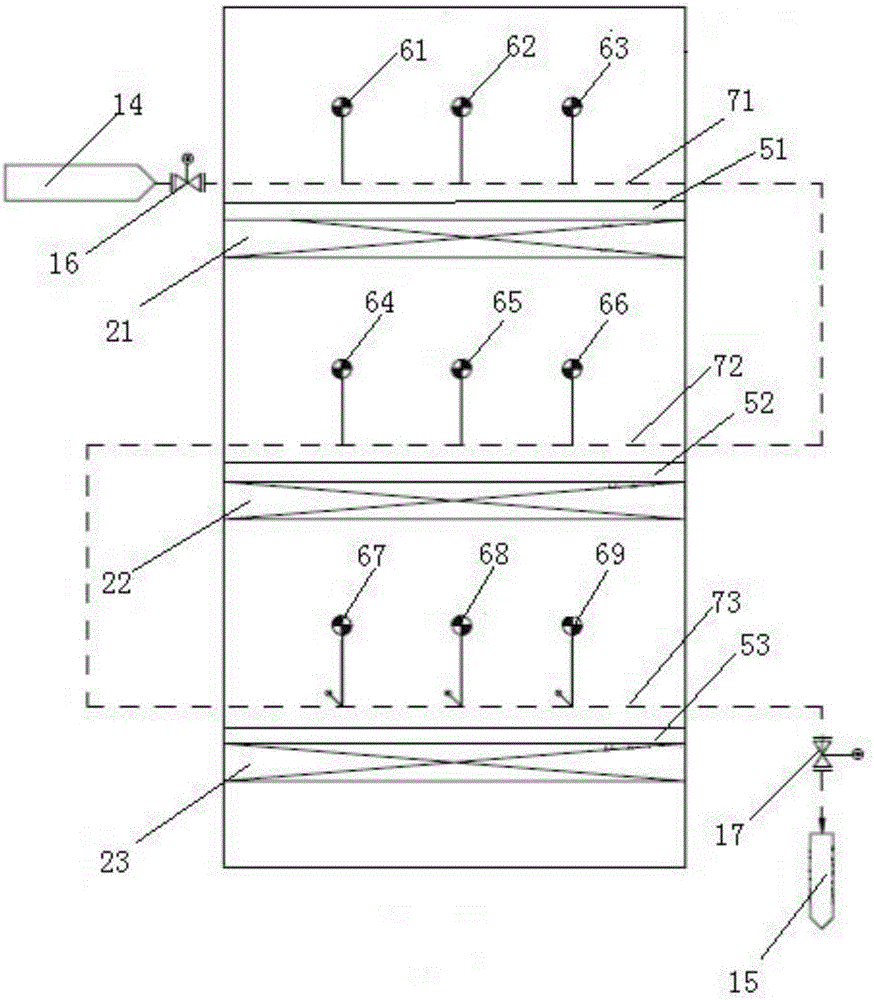

[0057] Such as figure 2 As shown, the difference from Example 1 is that it also includes a steam soot blowing device, which is arranged in the box of the denitration reactor, and the steam soot blowing device includes three steam soot blowing pipelines. The soot blowing steam inlet 14 of the boiler body is located outside one side of the box body in the denitration reactor. The first steam soot blowing pipeline 71 is located in the middle box of the denitrification reactor, the soot blowing steam inlet 14 of the boiler body is connected to the inlet end of the first steam soot blowing pipeline 71, and the first steam soot blowing pipeline 71 is located in the first screen Above the plate 51 , a first steam soot blower 61 , a second steam soot blower 62 and a third steam soot blower 63 are arranged on the first steam soot blowing pipeline 71 . The second steam soot blowing pipeline 72 is located in the box in the denitrification reactor, the inlet end of the second steam soot...

Embodiment 3

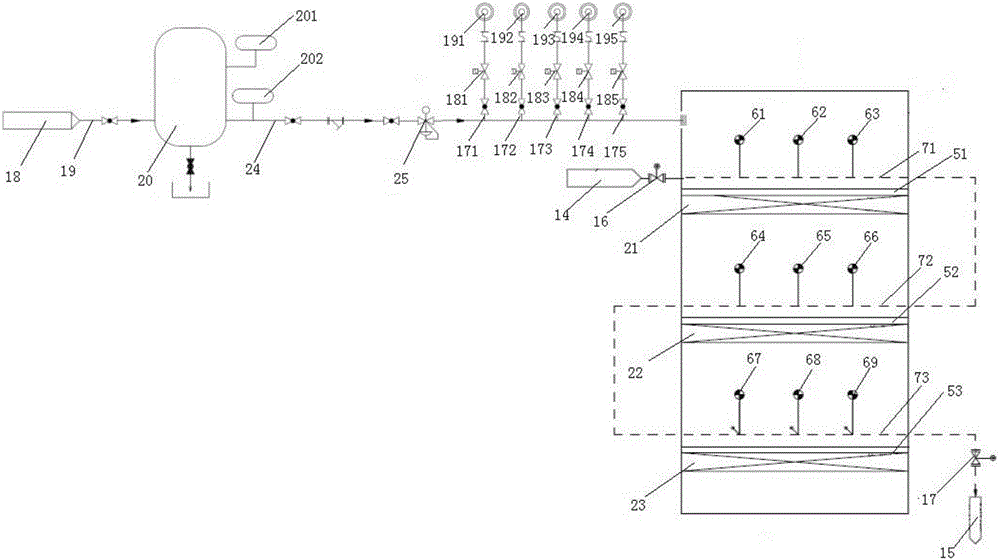

[0059] Such as image 3 As shown, the difference from Example 2 is that it also includes a sonic soot blowing device, and the sonic soot blowing device is arranged outside the box body 1 in the denitration reactor. The air inlet 18 is connected to an inlet end of an air inlet pipe 19 . The compressed air tank 20 is provided with an air inlet and an air outlet, the air inlet of the compressed air tank 20 is connected with the outlet end of the air intake pipe 19, the air outlet of the compressed air tank 20 is connected with the inlet end of the air supply pipe 24, and the air supply pipe 24 The outlet end of the outlet port is connected with the side wall of the box body in the denitrification reactor, the outlet end of the air supply pipe 24 is located above the first steam soot blowing pipeline 71, the compressed air tank 20 is provided with a first pressure gauge 201, and the air supply pipe 15 A second pressure gauge 202 is provided on the inlet end. The regulating valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com