Medium and low temperature wide-load SCR (Selective Catalytic Reduction) denitration device and method

A denitrification and low temperature technology, applied in the field of flue gas denitrification, can solve the problems of increasing the volume of denitrification devices and the cost of catalysts, and achieve the effects of saving equipment investment and operating costs, prolonging life, and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

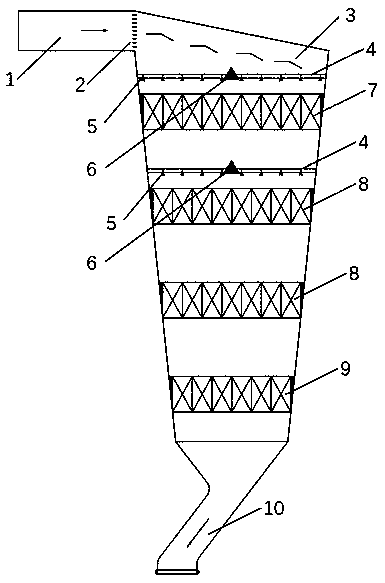

[0031] Such as figure 1 As shown, a medium-low temperature wide-load SCR denitrification device is installed behind the dust collector, including the denitrification device body. The denitrification device body is equipped with a high-temperature electrostatic precipitator flue 1, a flue deflector 2, and an inlet deflector 3. , rectifying grid 4, ammonia injection grid 5, temperature sensor 6, medium and low temperature catalyst layer 7, medium and high temperature catalyst layer 8, backup catalyst layer 9 and outlet flue 10, the flue gas inlet is set above the denitrification device body, and the flue gas The outlet is set at the bottom of the denitrification device body, the top of the denitrification device body is an inclined surface with an inclination angle of 30~40°, the shell of the denitrification device body is at an angle of 80~85° with the horizontal plane, and the flue gas inlet is provided with a flue guide plate 2 and The inlet deflector 3 and the flue deflector...

Embodiment 2

[0036] O in simulated flue gas 2 The volume fraction is 6%, NO x The concentration is 2000ppm, the balance gas is N 2 , its airspeed is 50000h -1 , the flue gas flow rate is 80L / h, the flue gas temperature is controlled at 250-410°C, the flue gas flow rate inside the denitrification device is steadily accelerated, the medium and low temperature catalyst layer 7 and the spare catalyst layer 9 are selected from the Mn-V-W-Ti system catalyst, the medium and high temperature catalyst The V-W-Ti system catalyst is selected for the layer, and the contact time between the flue gas and the catalyst is controlled to be about 200ms, which is beneficial to the diffusion, adsorption, reaction, and desorption and diffusion of the reaction gas in the micropores of the catalyst.

[0037] After the inlet flue gas passes through the high-temperature electrostatic precipitator, the flue 1 and the flue deflector 2 enter the interior of the denitrification device, and the airflow direction is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com