Full-working-condition auxiliary denitration system and running method

一种全工况、脱硝的技术,应用在燃烧方法、分离方法、化学仪器和方法等方向,能够解决催化剂活性退化、催化剂活性降低、脱硝效率下降等问题,达到环保效益好、提高给水温度、提高能量利用率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

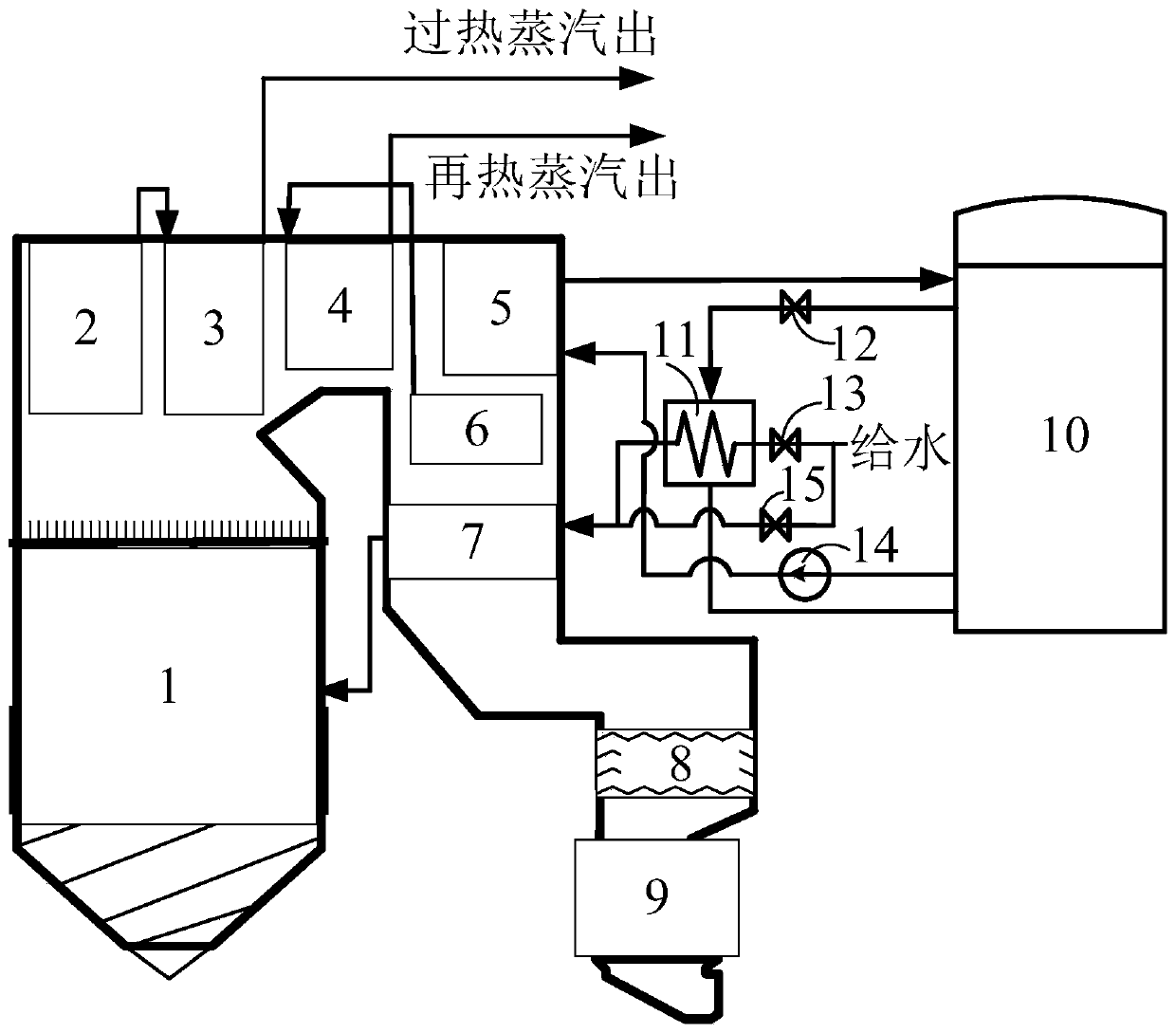

[0018] Such as figure 1 As shown, the present invention is an auxiliary denitrification system under all working conditions, including a water wall 1, a panel superheater 2, a final superheater 3, a final reheater 4, a heat storage medium heater 5, a low temperature Reheater 6, economizer 7, SCR denitrification device 8, air preheater 9, also includes heat storage medium tank 10, heat storage medium and feed water heat exchanger 11, heat storage medium outlet regulating valve 12, feed water adjustment Valve 13, heat storage medium pump 14 and bypass feed water regulating valve 15; the inlet of the heat storage medium heater 5 is connected with the cold heat storage medium outlet of the heat storage medium tank 10 through the heat storage medium pump 14; the heat storage medium The outlet of the heater 5 communicates with the heat sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com