Low-temperature carbon-based combined desulfurization and denitrification flue gas system and use method thereof

A technology for desulfurization, denitrification, and flue gas, which is applied in the field of combined desulfurization and denitrification flue gas systems, can solve problems such as complex operation and wear, and achieve the effects of uniform gas distribution, large windward area, and reduced equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

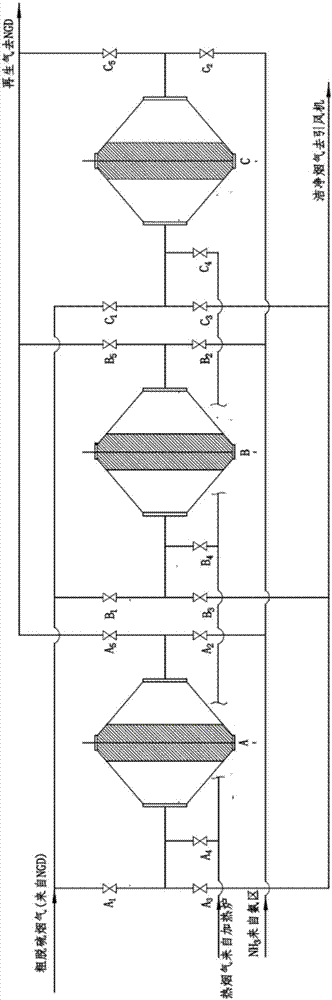

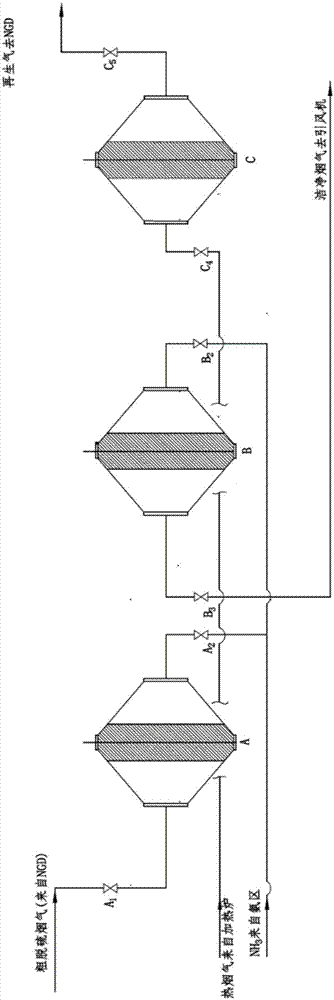

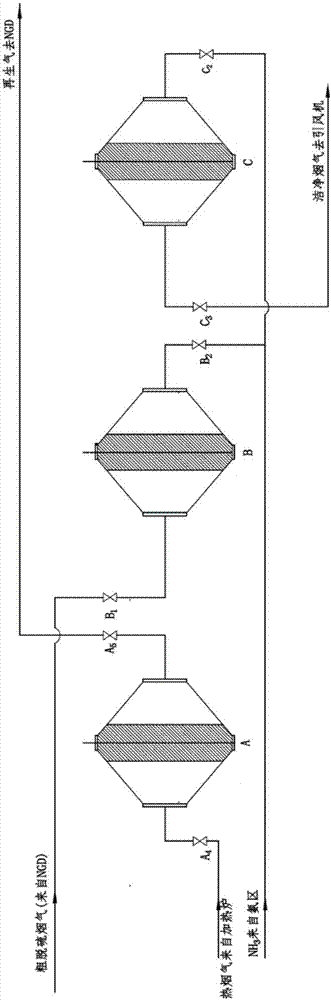

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] The carbon-based combined desulfurization and denitrification flue gas system is part of the coupling process system of flue gas desulfurization (NGD) with high-rate ash-calcium circulation and carbon-based selective catalytic reduction and oxidation (C-SCR and C-SCO). The desulfurized flue gas enters the activated coke combined desulfurization and denitrification device to complete fine desulfurization and C-SCR and C-SCO denitrification. After the activated carbon-based catalyst is deactivated, the whole bed is regenerated. The heat medium required for regeneration is a small amount of clean flue gas that is pressurized by the circulating fan and reheated by the boiler furnace. The regeneration gas produced by carbon materials is carried out of the combined desulfurization and denitrification unit by the heat medium, and mixed with the fresh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com